Front Page

Desiccant Air Dryers

AHLD E-Series

Heatless Regenerative

Models 70, 100, 150, 200, 250, 300, 350,

450, 500, 600, 750, 1000, 1250, 1500,

2000, 2500, 3000, 3500, 4500, 5000 scfm

Installation

& Operations

Manual

Eective October 2017

AHLD Series | Heatless Regenerative Desiccant Air Dryer

2

DRYER DATA SHEET

INTRODUCTION

Model Number: Serial Number:

Dryer Type: Date of Manufacture:

Ship Date: Installation Date:

Customer Name:

Customer Address:

Customer City: State/Zip:

Accessories:

Other:

Thank you for purchasing Aircel’s AHLD E-Series Heatless Regenerative Desiccant Air Dryer with integrated Energy Management

Purge Reduction System. You are now the proud owner of one of the nest desiccant dryers on the market. Aircel AHLD E-Series

dryers are engineered and manufactured to provide you with many years of trouble-free service and provides energy ecient

operation by reducing the overall dry purge air required for regeneration, saving energy and money. To ensure that you get rst

class service from this equipment, we recommend you take some time and read the contents of this manual.

This manual contains all the information required for installing and maintaining your new equipment. It also includes the safety

procedures and corresponding drawings. We strongly suggest that all personnel involved with the machine, read the entire

contents of the manual before proceeding with the installation or maintenance activities.

The manufacturer reserves the right to make changes without any prior notication and is not obligated in any manner.

Infomration in this manual is deemed current at the time of publication and Aircel disclaims all liability for any errors resulting in

any loss or damage.

If you have questions, need additional copies, or would like to schedule an Aircel service technician viist, contact your distributor.

Heatless Regenerative Desiccant Air Dryer | AHLD Series

3

DRYER DATA SHEET

Dryer Inlet Air Flow Rate:

Dryer Inlet Temperature:

Dryer Ambient Temperature:

Dryer Voltage:

Dryer MCA Minimum Circuit Ampacity:

Dryer MOP Maximum Overcurrent Protection:

Dryer Operating Pressure:

Dryer Maximum Operating Pressure:

Dryer Vessel Pressure Relief Valve Setting:

Dryer Desiccant Type:

Dryer Desiccant Weight Total for System:

Dryer Outlet Dew Point:

Dryer Control Time Cycle:

Dryer EMS Dew Point Sensor Setting (for sensor outlet dew point):

High Dew Point Setting:

Demand Cycle Setting:

Outlet Dew Point Readout on Display:

Electrical Drawing Number:

Mechanical Drawing Number:

PLC Software Program Number:

Control Air Filter Element Number:

Inlet Pre-Filter Element Number (option):

Outlet After-Filter Element Number (option):

Inlet Valve:

Purge Exhaust Valve:

Vessel National Board Number (Left and Right Vessels):

Dryer System Weight:

AHLD Series | Heatless Regenerative Desiccant Air Dryer

4

TABLE OF CONTENTS

Dryer Data Sheet 2

Introduction 2

Dryer Data Sheet 3

Safety Precautions 5

Safety Symbols 6

General Safety Instructions 7

Desiccant Safety Precautions 8

Why We Need Compressed Air Dryers 9

Purpose and Intended Use 9

Inspection on Arrival 9

Features & Options 10

Design Parameters 11

Dryer Description 11

How It Works 11

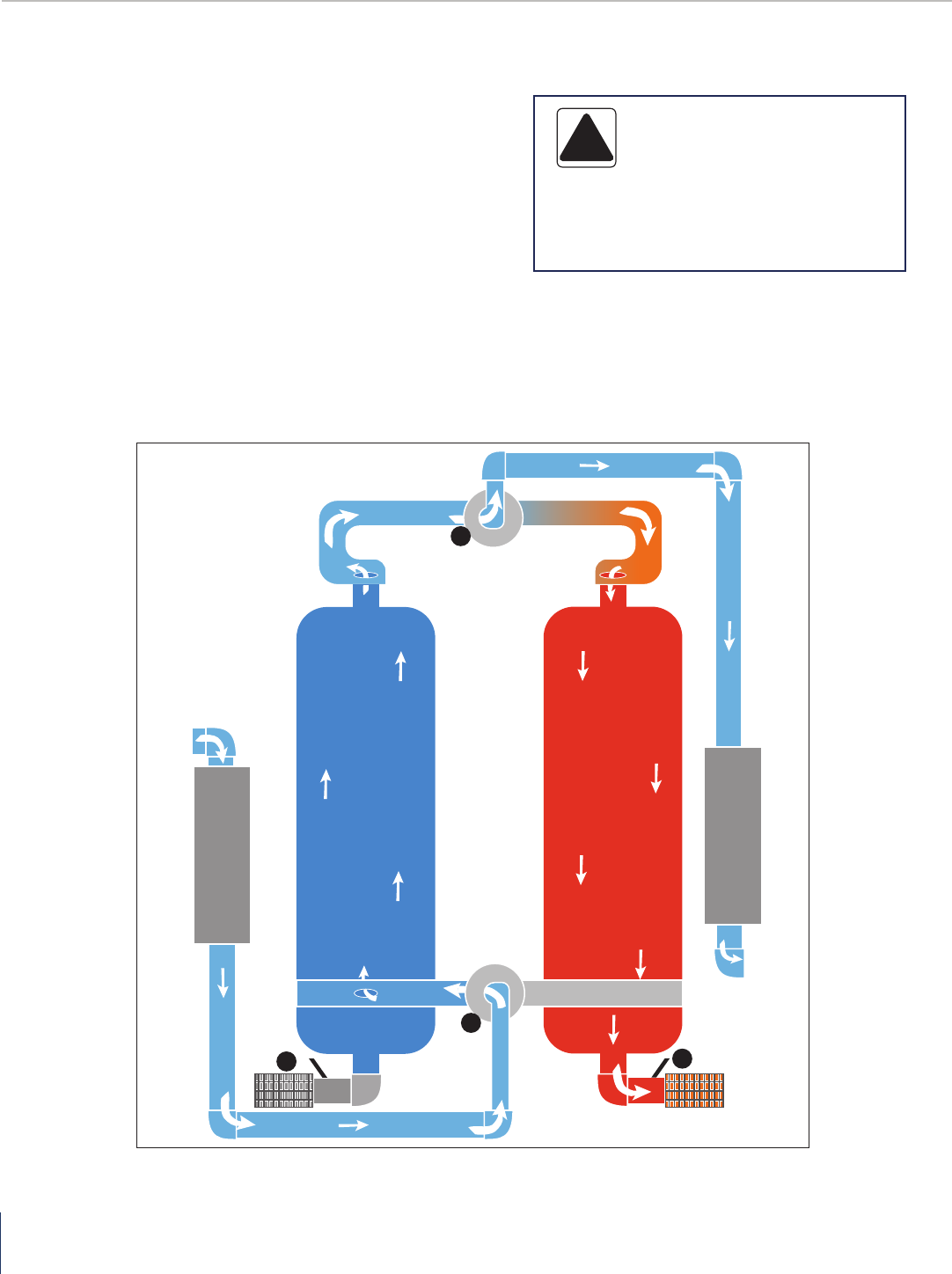

Flow Diagram 12

Installation 13

Pre-requisites for Installation 13

Location 13

Typical Installation Diagram 13

Installation Steps 14

Start-Up and Shut Down Procedures 15

Sequence of Operation 16

Maintenance 17

Weekly Checklist 17

Semi-Annual Checklist 17

Annual Checklist 17

Normal Operation Setup 18

Aircel Programmable Controller (APC) 19

System Navigation 19

Dryer Operations 20

Main Screen Navigation 24

Control Menu Navigation 24

Control Menu Operation 25

Settings Screen Operation 25

Time Control Main Navigation 26

Time Control Menu Operation 26

Analog Screen Navigation 27

Hours of Operation Screen Navigation 27

Alarm Screen Navigation 28

Alarm Pop-Up Screens 29

Troubleshooting Table 30

Appendix 32

Desiccant Material Data Safety Sheet 32

Drawings 37

Service Notes 43

Warranty 47

Heatless Regenerative Desiccant Air Dryer | AHLD Series

5

Notice: For optimum performance, use only Aircel replacement parts.

Notice: For information and notes specific to custom designed and built dryers, reference the drawing package

provided with the unit. See warranty on manual back cover for custom engineered products.

NOTICE

Throughout this manual, signal words are present to advise of safety

precautions and/or standard practices. Obey these signal words as dened

below:

DANGER! - Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING! - Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION! - Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

Notice: used to address practices not related to personal injury.

WARNING!

GENERAL SAFETY PROCEDURES:

• Improper installation, operation, or maintenance may contribute to conditions in the work area or facility that could

result in personal injury and product or property damage. Check that all equipment is properly selected and sized for

the intended use.

• Consult and comply with national and local codes relating to fire or explosion and all other appropriate codes when

determining the location and operation of this equipment.

• Safe and efficient operation of the unit depends on proper installation.

• Authorities with jurisdiction should be consulted before installing to verify local codes and installation procedures. In

the absence of such codes, install unit according to the National Electric Code, NFPA No. 70-latest edition.

• A qualified installation and service agent must complete installation and service of this equipment.

• DO NOT weld on / to pressure vessel or modify it in any way.

• DO NOT remove, modify, or adjust protective or safety devices.

• Lock out power supply and depressurize system before performing maintenance or service work.

• DO NOT operate the equipment with the control panel door open.

AHLD Series | Heatless Regenerative Desiccant Air Dryer

6

SAFETY INSTRUCTIONS

Safety Symbols Used in Manual

IMPORTANT INFORMATION: Readers of the manual must pay extra attention to instructions and information

succeeding this symbol.

WARNING: This indicates that it is dangerous and could result in physical injury and death if the instructions are

not followed correctly.

ELECTRICAL DANGER HIGH VOLTAGE: This means that there is a risk of electrical shock and only authorized

personnel with proper gear must approach it.

HIGH NOISE AREA: All personnel are required to wear ear protectors before approaching the vicinity of the

equipment.

HAZARDOUS FUMES & GASES: Personnel must wear protective gear to prevent inhaling of the gases and fumes.

SUSPENSION POINTS: Look for these symbols before making any attempt to move or relocate your equipment

.

TIPS & SUGGESTIONS: Following these tips can make your work easier.

EXTREME CAUTION: This indicates that there might be possible risk of material damage and personnel are

advised to exercise extra caution.

!

X

Heatless Regenerative Desiccant Air Dryer | AHLD Series

7

GENERAL SAFETY INSTRUCTIONS

What You Must Do

1. Certified/authorized electricians must perform electrical work.

2. Electrical work must conform to the specifications indicated by Aircel and any local or state laws that may apply.

3. Personnel must wear appropriate safety gear before working on any electrical or mechanical aspects of the

machine.

4. Appropriate tools have to be used for all installation and maintenance work. If special tools are required and are

not available to the installation crew, contact the factory or your Aircel representative.

5. A copy of the Operation Manual must be made available to all personnel involved with the installation, operation,

and maintenance of the equipment.

6. Before performing any maintenance operations on the equipment, the unit must be shut down, isolated, electrical

power removed, and completely depressurized.

7. To ensure compatibility and continued trouble free operation, only genuine Aircel parts must be used.

Safe Operating Procedures

1. Pressurize and depressurize compressed air SLOWLY! Always open air valves slowly when pressurizing the airline

system or equipment. Repair air slowly when depressurizing your air system or equipment.

2. Circuit breakers, fusable disconnect, and wiring should conform to national and/or local electrical codes. Make

certain that qualified electrical personnel perform the electrical installation for this unit.

3. Only use original fuses for the rated voltage and current.

4. Shut down the unit in the correct recommended procedure.

5. Before any work on system, always depressurize the unit and remove all electrical power.

6. After shut down, put up warning notice to prevent the unit from being switched “ON” accidentally.

7. Inspect all piping, hoses, and connections. Make sure that all hoses are in good condition and are rated for the

correct working pressure. Do not allow hoses to come into contact with oils, chemicals, or sharp objects.

8. Secure condensate drain lines. Unsecured, flexible drain lines may whip violently under pressure and may cause

bodily harm.

Aircel air dryers do not remove carbon monoxide (CO) and are not safe for human respiration (breathing). Breathing air

must be at least Grade D quality as described in Compressed Air and Gas Association (CAGI) commodity specifications

67.1-1966. User may refer to OSHA 29 CFI 1910.134 for special precautions and equipment suitable for breathing air

applications. Aircel disclaims any liability whatsoever for loss, injury, or damage.

What You Must Not Do

1. Do not make any constructional changes to the unit. Only Aircel or its authorized representatives with the prior

approval can perform any constructional work on the machine.

2. Do not use foreign parts.

3. Compressed air from the dryers is not to be used for breathing purposes - install a breathing air package to

ensure conformance with OSHA regulations.

4. Do not disable or disengage any protective equipment used on the machine.

X

!

!

AHLD Series | Heatless Regenerative Desiccant Air Dryer

8

DESICCANT SAFETY PRECAUTIONS

Desiccant First Aid

Recommendations

INHALATION

Use a contoured dust mask during loading and

unloading operations. If high concentrations are inhaled,

immediately move to fresh air. Keep person calm. If

not breathing, give articial respiration. If breathing is

dicult, give oxygen. Call a physician.

SKIN CONTACT

In case of contact, immediately flush skin with plenty of

soap and water for at least 15 minutes.

EYE CONTACT

In case of contact, immediately flush eyes with plenty of

water for at least 15 minutes. Call a physician.

SPILLS

Clean accidental spills by vacuuming, sweeping, or

flushing to a sewer treated for suspended solids. Avoid

creating excess dust.

WARNING!

INHALATION, SKIN, & EYE IRRITANT:

The desiccant used in this equipment is not considered

hazardous. Contact with and disposal of desiccant

must be in accordance with the relevant MSDS and

all local codes and regulations. The following lists the

more common safety measures to be observed during

loading and unloading operations. Reference the MSDS

in the appendix for complete safety measures.

!

Heatless Regenerative Desiccant Air Dryer | AHLD Series

9

WARNING!

• Failure to lift the unit correctly can result

in sever personal injury or property

damage.

• Use appropriate lifting equipment and

adopt all safety precautions needed for

moving and handling the equipment.

• A hand cart, fork lift, or crane is

recommended for unloading and

installation.

• Lift unit by lifting lugs and frame only. Do

not lift by piping.

!

WARNING!

• Follow proper lock out/tag out

procedures before performing service or

maintenance work.

• Electrical installation must be performed

by a qualied electrician and comply with

all applicable national and local codes.

!

CAUTION!

• A copy of the Operation Manual must be

made available to all personnel involved

with the installation, operation, and

maintenance of the equipment, to avoid

injury to personnel or property damage.

• Appropriate tools must be used for all

installation and maintenance work, to

avoid injury to personnel or property

damage.

!

Why We Need Compressed Air Dryers

Untreated compressed air contains many contaminants such

as water, compressor oil, pipe scale, and contamination from

ambient air. All these contaminants cause excessive corrosion,

erosion, freezing, and regenerative type dryer system with all

recommended ltration will remove these contaminants to

harmless levels. The end result is that instruments that come

in contact with the dry compressed air stay clean and do not

corrode, therefore lasting much longer. Products that may

come in contact with clean, dry, compressed air are virtually

unaected. Therefore, rejection rates are reduced.

Purpose and Intended Use

Misuse or modication of this equipment may result in personal

injury. Do not misuse or modify. The high eciency heated

regenerative desiccant dryer is used exclusively for purifying

compressed air in non-hazardous locations.

The state-of-the-art system is designed and constructed

in accordance with the rules and regulations regarding

adsorption technology and industrial safety. There are hazards

accompanying this type of product if not operated for the

intended purpose by trained and specialized personnel.

Inspection on Arrival

All heated regenerative desiccant dryers are tested and

operated before shipment. However, shipping vibration may

cause damage such as loosening of certain parts. To ensure

smooth installation, it is recommended that immediately upon

receipt of the unit, the system is checked for the following:

1. Inspect unity on delivery.

2. Report any damage to the delivery carrier.

3. Request a written inspection report from the Claims

Inspector to substantiate the claim.

4. File claims with the delivery carrier.

5. Compare unit received with description of product ordered.

Check the serial plate label and make sure that it is the

correct Model was ordered. Note the equipment Capacity

and Power Supply requirements and ensure that they are

in accordance with your specifications. The rated conditions

of the dryer are indicated on the serial plate label. If there

is any discrepancy, contact your representative listed on

the manual back cover.

6. Vibration during shipping can loosen the connections.

Inspect all pipe and tubing and make sure they are all

tightened and secured.

7. Report incomplete shipments to the delivery carrier and

your service representative.

AHLD Series | Heatless Regenerative Desiccant Air Dryer

10

FEATURES & OPTIONS

Standard Features

• Integrated Energy Management Purge Reduction System for ecient energy savings and reduced cost of operation.

• Optimal tower size for low velocities reducing desiccant uidization, and high contact time for ecient low dew point

performance.

• Tower pressure relief valves.

• Standard design capacity based on 100 psig, 100°F inlet air, 100°F ambient air, and Pressure dew point of -40°F.

• Purge exhaust muers for quiet operation.

• Tower pressure gauges for additional visual operation of dryer operation.

• Stainless steel desiccant supports and air diusers to prevent channeling.

• Counter-current reactivation for ecient desiccant regeneration.

• PLC Controlled Electrical System

• Adjustable (5 min., 10 min.) cycle times: 10 minute cycle for the standard -40°F Pressure dew point outlett dew point

systems, 5 minute cycle used in the optional -100°F Pressure dew point outlet dew point systems.

• Controlled repressurization to slowly repressurize the regenerated vessel to line pressure prior to switch over preventing

desiccant bed movement and attrition.

• Fail safe design: Failure of power and/or pilot air causes the purge exhaust valves to close, eliminating loss of air pressure.

The system also provides uninterrupted drying air ow, preventing a deadheading aect.

• Control pilot air lter provides clean air to air control system for long trouble-free reliable operation.

• Desiccant towers are designed, fabricated, and stamped according to ASME code.

• Desiccant ll and drain ports for ease of desiccant replacement.

• Structural steel frame.

• Highly reliable non-lubricated air inlet and outlet valves (APV) Automatic Piston Valve (AHLD 70 E - AHLD 750 E) and high

performance, non-lubricated buttery valves (AHLD-1000 E - AHLD-1500 E).

• Highly reliable angle seat design purge exhaust valves.

• Tower operating LED status lights (left and right tower dryer, left and right tower regenerating).

• On/O switch and power On light.

• NEMA 4 weather resistant electrical system construction.

Additional Options

• -100°F outlet pressure dew point.

• Failure-to-shift alarm with pressure transducers.

• Outlet dew point sensor with dew point readout on system display.

• High humidity alarm.

• Outlet dew point 4-20 ma signal.

• Mounted, piped, and wired ltration packages.

Heatless Regenerative Desiccant Air Dryer | AHLD Series

11

How It Works

1. Moisture saturated compressed air enters the coalescing

pre-lter, where aerosols are coalesced then drained via

an automatic drain system.

2. The moist water vapor-laden inlet air free of liquid

water ows to the inlet of the dryer through the APV

(Automatic Piston Valve) (A), which diverts the inlet air to

one of the towers - in this example, Tower 1.

3. Air ows upward through the adsorbent bed removing

the moisture vapor; the dried airow exits the tower

through the outlet valve (B), owing to the outlet

particulate after lter, which removes particulates

from the air stream. Clean and dry air now ows to the

customer process air distribution system.

4. As one tower is drying air, the other tower will be

regenerating (purging) the adsorbent bed. In this

example, Tower 2 will be regenerating. Prior to

regeneration, the exhaust valve (C) is opened and the

tower is depressurized to near atmospheric pressure, the

tower will now be regenerating. During the regenerating

process, a small portion of dry outlet compressed air is

used, 15% on average based on standard design capacity

of 100 psig, 100°F inlet air, 100°F ambient air, and

pressure dew point of -40°F.

5. The dry regeneration airow is channeled through

the outlet orice to the regenerating tower, removing

moisture from the adsorbent bed and exits the

regenerating tower through exhaust valve (C) and

exhaust muer to ambient. After regeneration cycle

is complete, valve (C) closes, causing Tower 2 to

repressurize to line pressure.

6. Next, the tower will switch when exhaust valve (D)

opens, causing Tower 1 to depressurize and regenerate.

Simultaneously, the inlet and outlet APV valves (A) will

shift the pistons to the low pressure Tower 1, causing

the inlet airow to be diverted to Tower 2, which will now

be the drying tower. This switching process will continue

repeatedly.

7. The dryer control system is completely automatic and

cycles the system through the drying and regeneration

cycles. The standard cycle drying time is 5 minutes,

regeneration cycle is 4 minutes, and repressurizing cycle

is 1 minute.

DESIGN PARAMETERS

DRYER DESCRIPTION

Type of dryer: Desiccant

Power supply: 460 Volt / Three Phase / 60Hz

Desiccant type: Premium Grade Activated Alumina

All Models

Parameter

Description Air Pressure

Air Inlet

Temperature

Ambient

Temperature

Maximum 135 psig 120 (°F) 120 (°F)

Minimum 60 psig 40 (°F) 38 (°F)

AHLD Series | Heatless Regenerative Desiccant Air Dryer

12

A

D

B

C

D

Pre-Filter

Tower 1 Tower 2

After Filter

TYPICAL SCHEMATIC FLOW DIAGRAM

8. The Aircel AHLD E-Series Heatless Dryer incorporates a

unique energy saving control system to reduce purge

air loss with its integrated Energy Management Purge

Reduction System. This system utilizes a moisture

sensor sampling the air from mid-bed of the on-stream

drying tower, after the xed purge time is complete,

the regenerating/purging tower will repressurize. If the

moisture sensor senses a low moisture condition or low

load in the drying tower, the drying tower will remain

in the drying mode after the xed drying time cycle for

an extended period of time. The end result is an overall

purge reduction and signicant energy savings.

CAUTION!

• Do not misuse or modify under any

conditions. Misuse or modication of this

equipment may result in personal injury.

!

Heatless Regenerative Desiccant Air Dryer | AHLD Series

13

INSTALLATION

Pre-requisites for Installation

To ensure a safe and smooth installation, we recommend you

go through the steps indicated below:

• Make sure that all personnel involved have read this

operation manual thoroughly. If you have any questions,

please contact your Aircel represenative or the factory

and we will be glad to assist you. If you need help with

the commissioning, we will be glad to schedule an

Aircel factory service technician to visit your site and

commission the dryer for a nominal fee.

• Have extra copies of the operation manual.

• Special care must be taken while transporting the unit to

the installation site.

• Dryer must not be moved or lifted by the attached piping.

Location

• Careful consideration should be given to the location of

the dryer in order to assure optimum results. Ensure that

the load bearing weight of the floor is adequate for the

weight of the dryer.

• The dryer should be located in an open area and a level

ground. Dryer should be bolted to the floor to eliminate

vibrations.

• The ambient temperature should be between 40°F and

100°F. Low temperature could affect the dryer process

and result in high outlet dew point.

• In conditions where the ambient drops below freezing,

Aircel recommends the use of heat trace on any

coalescing filter sumps and drain lines and the use of

heated type draings.

• Dryer and accompanying filters should be installed with

at least 2-5 feet clearance from the adjoining walls to

provide easy access for routine maintenance.

Drain

Valve

Air or Water

Cooled

Condenser

Air

Compressor

Drain

Valve

Dry Air

to Plant

Drain

Valve

Drain

Valve

After Filter

Pre-Filter

Separator

TYPICAL INSTALLATION DIAGRAM

AHLD Series | Heatless Regenerative Desiccant Air Dryer

14

INSTALLATION

Only qualied personnel should make electrical and

mechanical connections.

• EQUIPMENT FOR INSTALLATION: This dryer does not

need any special tools for installationFoundation: Dryer

should be mounted on a suitably structured flat and level

floor or base that is free from vibration. Special care must

be used when lifting the dryer to prevent tip-over.

• MOUNTING: Bolt dryer to the foundation using the bolt

holes provided in the frame.

• PIPING: Connect the inlet of the dryer to the moist gas

from the compressor/receiver/inlet filter. Install the

inlet piping and the inlet shutoff valve, Install the Outlet

piping and the outlet shutoff valve (a union with a valve

by-pass can be installed at the inlet and outlet valves to

accommodate isolation of the dryer for maintenance).

Compressed air piping has to be least the same size as

the of the inlet and outlet connections of the dryers.

Larger pipe sizes can be used with reducers.

• BACK PRESSURE REGULATOR: Install backpressure

regulator to prevent any possibility of fluidization of

the desiccant bed. When there is a sudden increase

in the demand for compressed air downstream of the

dryer, a huge pressure drop develops and can affect

the performance of the dryer and the drying material

(desiccant).

• DESICCANT: Make sure that the dryer towers are filled

with desiccant. Larger dryers may have desiccant shipped

separately – in which case, the media has to be filled into

the pressure vessels from the desiccant fill ports. Care

must be taken when filling the media and it must be done

gradually to prevent powdering.

• MUFFLER: If the event that mufflers have been shipped

loose, they must be installed and secured.

• BY-PASS: If the dryer is not supplied with optional by-pass

valve it is highly recommended that by-pass valve be

installed around the dryer and filters. These by-pass shut-

off valves will permit the dryer and filters to be removed

from the compressed air system for servicing without

shutting down the entire compress air system.

• ELECTRICAL: Make all electrical connections to the dryer

as shown on the wiring diagram. Special care must be

taken in connecting the proper voltage as indicated on the

specification sheet and wiring schematic.

• ADDITIONAL VALVING/PIPING: When installing

equipment or components keep in mind the serviceability

of the equipment and provide additional valves to isolate,

bypass, and to depressurize as needed.

• EXHAUST: If you intend to vent your exhaust with

additional piping, the discharge piping from the exhaust

should not be piped upward without arrangement for

removing trapped condensate. Make sure that you do not

apply a backpressure on this exhaust system. If exhaust

piping is to be extended, try to stay within 15 to 20 feet

and use the next larger pipe size.

NOTE: It is mandatory that dryer be grounded. Use of

your plants frame as a ground may cause problems with

the control. A fused disconnect is not supplied with this

equipment therefore one must be supplied by customer. All

electrical fuses, breakers, etc. should be properly sized.

Aircel is not liable for any code violations, component damage,

downtime, or consequential damage related to customer

supplied electrical components and connections.

Heatless Regenerative Desiccant Air Dryer | AHLD Series

15

START-UP AND SHUT DOWN PROCEDURES

Start-Up Procedure

At any point during the process of startup or shutdown,

you notice anything unusual; we recommend you refer to

the operation manual immediately. If you cannot nd the

answer in the troubleshooting section, contact your Aircel

representative or the factory at once.

1. Ensure that the dryer is connected to a suitable

compressed air supply. Make sure that the pressure of

the supply is equal to the normal operating pressure of

the dryer.

2. Check to make sure the “shut-off” valves are closed and

that by-pass valve is open.

3. Close all manual drain/vent valves.

4. Slowly pressurize the dryer by gradually (slowly) opening

the inlet shut-off valve to the OPEN position.

5. When both towers of the dryer are completely

pressurized, check the complete system for possible air

leaks. Use soap and water to test all joints and fittings. If

any leaks are detected, immediately depressurize the unit

and correct the leaks.

6. Make certain that nay automatic condensate drain

isolation valves are in the open position so proper

condensate draining can occur.

7. When normal operating pressure is reached, switch on

electrical power (Turn switch to ON position).

8. With by-pass valve closed, open the outlet valve slowly to

allow air downstream.

9. When energized one of the towers should depressurize.

10. Check the operation of several cycles completely by

following the control panel display screen operation, the

panel lights on the electrical box, and the tower pressure

gauges to make certain the dryer system is operating as

displayed. Also refer to the how it works section, flow

diagram, electrical drawing, dryer control display screen

descriptions, and sequence of operation in this manual

for reference.

11. Check the drain valve for proper operation and discharge

of liquid (filters and separators, etc.).

12. Near the dryer outlet (APV) valve, check the control air/

pilot air regulator secondary pressure, the regulator

gauge should read 100 psig. Increase or decrease

regulator knob to achieve a 100 psig control air secondary

pressure reading.

13. Make certain the purge exhaust valves slowly open

within an 8 to 12 second time period, some adjustment

of the flow control valve attached to the actuator may be

required, after adjustment tighten down the locking collar.

14. Make certain a slight amount of air flow is felt at the end

of the EMS RH sensor sample cell exhaust coil tube (this

is normally located at the back of the dryer) adjust the

needle valve to give more or less flow.

15. Review the dryer system display screen shots (in this

manual) to make certain the parameters are set as

needed in the customer dryer.

16. Purge air flow is preset and not adjustable.

After the initial startup, the dryer operation is completely

automatic. To understand the details of the operation, we

recommend you use the how it works section, flow diagram,

electrical drawing, dryer control display screen descriptions,

and sequence of operation in this manual for reference.

Shut-Down Procedure

At any point during the process of startup or shutdown,

you notice anything unusual; we recommend you refer to

the operation manual immediately. If you cannot nd the

answer in the troubleshooting section, contact your Aircel

representative or the factory at once.

1. Slowly OPEN the by-pass valve.

2. Slowly CLOSE the Inlet and outlet “shut-off” valves.

3. To depressurize the dryer after the Dryer is isolated. Turn

the power ON … a purge exhaust valve will open and

the dryer system starts to depressurize, also the manual

vent valve on the outlet afterfilter can be opened to

depressurize the Dryer until the tower pressure gauges

read ‘0’ psig.

4. Switch off electrical power after both towers have been

depressurized.

AHLD Series | Heatless Regenerative Desiccant Air Dryer

16

SEQUENCE OF OPERATION

1. STEP ONE - Vessel 2 Depressurizing (0 - 5 seconds):

Vessel 2 (T2) purge exhaust pilot solenoid valve is

energized which supplies control air to the purge

exhaust valve (V4) which opens slowly, depressurizing

vessel 2 (T2). Simultaneously the inlet valves V1 and V2

shift positions with a pneumatic signal from vessel 2

(T2) purge exhaust pilot solenoid valve to the inlet tower

selector pneumatic pilot valve which in-turn supplies a

pneumatic signal to the inlet valve (V1) and close valve

(V2), directing the inlet air to vessel 1 (T1) to be drying

the air. The air flows up through the desiccant bed and

exits to the outlet valve (V5) to the outlet particulate

filter then to custom dry process air system.

2. STEP TWO - Vessel 2 Regenerating (6 - 240 seconds):

Step 2 is a continuation of step 1 except vessel 2 (T2)

will be regenerating, vessel 2 (T2) purge exhaust valve

(V4 is still open vessel 1 (T1) is drying the inlet air. A

small portion of dry outlet air from vessel 1 (T1) (15%

average based on standard design capacity of 100 psig,

100°F inlet air, 100°F ambient air and PDP of -40°F is

taken through a small orifice in the outlet line and used

to regenerate the desiccant bed in vessel 2 (T2) until

240 seconds has been reached.

3. STEP THREE - Vessel 2 Repressurizing (241 - 300

seconds):

Vessel 2 (T2) purge exhaust pilot solenoid valve will

de-energize causing vessel 2 (T2) purge exhaust valve

(V4) to close, this allows vessel 2 (T2) to repressurize to

line pressure, since air continues flowing through the

small outlet orifice pressurizing vessel 2 (T2). The inlet

tower selector pneumatic pilot valve maintains the inlet

valve (V1 & V2) positions.

4. STEP FOUR - Vessel 1 Extended Drying:

A few seconds before the end of repressurization

the AHLD E-SERIES Controller’s integrated Energy

Management Purge Reduction System looks at the

moisture sensor, if the moisture load is low enough,

vessel 1 (T1) will continue to dry for an extended drying

period until the moisture load has reached a set high

level, the controller will then advance to step 5 and

the vessels will switch. This feature reduces the overall

purge consumption saving energy and money.

5. STEP FIVE - Vessel 1 Depressurizing (0 - 5 seconds):

Vessel 1 (T1) purge exhaust pilot solenoid valve is

energized which supplies control air to the purge

exhaust valve (V3) which opens slowly, depressurizing

vessel 1 (T1). Simultaneously the inlet valves V2 and

V1 shift positions with a pneumatic signal form vessel

1 (T1) purge exhaust pilot solenoid valve to the inlet

tower selector pneumatic pilot valve which in-turn

supplies a pneumatic signal to the inlet air to vessel

2 (T2) to be drying the air. The air flows up through

the desiccant bed and exits to the outlet valve (V6) to

the outlet particulate filter then to the customer dry

process air system.

6. STEP SIX - Vessel 1 Regenerating (6 - 240 seconds):

Step 6 is a continuation of step 5 except vessel 1 (T1)

will be regenerating, vessel 1 (T1) purge exhaust valve

(V3) is still open, vessel 2 (T2) is drying the inlet air.

A small portion of dry outlet air from vessel 2 (15%

average based on standard design capacity of 100 psig,

100°F ambient air and PDP of -40°F) is taken through a

small orifice in the outlet line and used to regenerate

the desiccant bed in vessel 1 (T1) until 240 seconds has

been reached.

7. STEP SEVEN - Vessel 1 Repressurizing (241 - 300

seconds):

Vessel 1 (T1) purge exhaust pilot solenoid valve will

de-energize causing vessel 1 (T1) purge exhaust valve

(V3) to close, this allows vessel 1 (T1) to repressurize to

line pressure, since air continues flowing through the

small outlet orifice pressurizing vessel 1 (T1). The inlet

tower selector pneumatic pilot valve maintains the inlet

valve (V2 and V1) positions.

8. STEP EIGHT - Vessel 2 Extended Drying:

A few seconds before the end of repressurization

the AHLD E-SERIES Controller’s integrated Energy

Management Purge Reduction System looks at the

moisture sensor, if the moisture load is low enough,

vessel 2 (T2) will continue to dry for an extended drying

period until the moisture load has reached a set high

level, the controller will then advance to step 1 and

the vessels will switch. This feature reduces the overall

purge consumption saving energy and money.

Heatless Regenerative Desiccant Air Dryer | AHLD Series

17

MAINTENANCE

Maintenance

Prior to performing and maintenance on the dryer, all

personnel are strongly advised to familiarize themselves

with the equipment by reading the entire contents of

this operation manual. Aircel strongly recommends the

strict adherence of all the safety procedures prior to any

performing and maintenance activity on the dryer.

1. The pressure differential indicator referred to as the

“Delta-P” is a very good indicator of the state of the filter

elements. Maintenance personnel must pay attention

to these to keep the drying running with full efficiency

Change filter elements on a regular basis, once a year

maximum for a 1-shift operation. Change more frequently

if operating 2 or 3 shifts such as every 6 months.

2. The useful life of a filter element depends on the quality

of air. Free open areas for input and exhaust will ensure

lesser intake of dirt and particles.

3. Powder desiccant can accumulate in the muffler and

increase the backpressure in the regenerating tower

change mufflers on a regular basis typically every 2-3

months for optimum performance.

4. Oil and oil vaper can drastically reduce the life of the

desiccant. Take precautions to eliminate all traces of oil

from the airflow.

5. Fluctuating dew point indicates uneven drying and

regeneration between the towers, an exhaust valve may

not be working properly or muffler may be clogged or

dirty, also vessel diffuser screen may be clogged.

Weekly Checklist

1. Check all drain valves, prefilter, afterfilter and separators.

2. Check any pressure differential indicators (Delta-P) on

the pre-filter and afterfilter (filter elements should still be

changed on regular basis once a year maximum for a 1

shift operation. Change more frequently if operating 2 or

3 shifts such as every 6 months).

3. Check dryer for correct operation.

4. Verify dryer is purging at the purge exhaust, after dryer

depressurizes.

5. Check the dew point (if available) to ensure the dew point

is being achieved.

6. Check back pressure in regenerating tower, if more than a

few psig on the pressure gauge, clean or replace exhaust

mufflers (change mufflers on a regular basis typically

every 2-3 months for optimum performance).

Semi-Annual Checklist

1. Remove and inspect all filters for excessive particulate

loading and physical damage – if required replace

prefilters, afterfilters, pilot air filter and mufflers (filter

elements should still be changed on regular basis once

a year maximum for a 1 shift operation. Change more

frequently if operating 2 or 3 shifts such as every 6

months).

2. Check pressure differential indicator and if it turns red,

replace the element.

3. Remove exhaust mufflers. Knock out excess particulate

and back flow with dry compressed air. If particulate

cannot be removed completely change the exhaust

mufflers. Check backpressure in regenerating tower,

if more than a few psig on the pressure gauge, clean

or replace exhaust mufflers. (Change mufflers on a

regular basis typically every 2-3 months for optimum

performance).

4. Check desiccant condition. Powder in the mufflers is an

indication of the status of the desiccant.

5. Check all solenoid valves – coil condition and control

circuit.

6. Check dryer operation.

7. Inspect and clean inlet and outlet APV (Automatic Piston

Valves).

Annual Checklist

1. Replace elements in prefilters, afterfilters, and pilot air

filter.

2. Replace mufflers.

3. Recalibrate dew point analyzer probe (if used) or send

back to factory for recalibration.

4. Check inlet and outlet valve seals. Clean or replace as

needed.

5. Check dryer for proper operation

WARNING!

• Follow any proper lock out/tag out procedure

before performing service or maintenance work.

• Follow all safety procedures prior to performing any

maintenance activiting on the dryer.

!

AHLD Series | Heatless Regenerative Desiccant Air Dryer

18

NORMAL OPERATION SETUP

Normal Dryer System Operation Setup

The following operational sequence should be followed for normal dryer system operation.

1. Make certain all gauge isolation valves, vent valves,

instrument valves, pre-filter drain valves, etc. are in the

correct positions.

2. Make certain the system has been pressurized to line

pressure.

3. Ensure blower intake adjustment valve has been preset

and locked down. Slight adjustment might be needed to

maintain 400°F downstream of heater during the heat

regeneration cycle.

4. Verify control air has pressure, set at 100 psi

5. Confirm the valve upstream of the dew point sensor is

fully open, and valve downstream of the dew point sensor

is slightly open - a slight air flow should be noticed at the

end of the exhaust coil.

6. The Power On/Off switch is set to ON.

7. The System On/Off button must be turned On. This is

accomplished by pressing the System On button on the

control panel in the Main Menu screen. The color will be

green for on and red for off.

8. Service Mode should not be active. Service Mode will not

be visible or shown on the Running Sequence screens

when not active. If Service Mode is shown, the service

routine is active and needs to be place into normal

operation. To deactivate Service Mode from the Running/

Step screens, press the Screen Unlock button until it starts

blinking, then press the Main Menu button, displaying

the Control/Main screen. Next, press the Service Menu

button to activate the service screen. From here, press

the Deactivate Service button. The Service Mode that was

visible on each screen will disappear and the dryer will

resume normal operation.

9. Check the temperature settings in the Control/Main

menu by pressing the Temp Settings button and verify all

settings are correct as needed.

10. Dew point Demand can be turned On or Off in the

Control/Main menu. When On (Green in color), Dew point

Demand is energy saving demand mode, extending the

drying period if below outlet Dew point Demand setting in

the Temp Settings screen. When the Dew point Demand

button is Off (Red in color), the dryer is in fixed time

mode, switching continuously on a standard time cycle.

11. Dry Cool Purge can be turned On or Off in the Control/

Main menu. When On (Green in color), a portion of the

dry air outlet will help cool the regenerating bed and

minimize the pressure dew point swing at switchover.

12. Blower Cool can be turned On or Off in the Control/

Main menu. When On (Green in color), the heater sheath

cooling process will initiate for a total of 8 minutes prior

to the Dry Cool Purge.

13. Typically, the Running Screens/Steps screens should be

displayed on the system screen when in operation. Other

screens (such as the Flow Diagram) can be displayed as

the normal operation screen, if needed.

14. Verify no Common Shutdown alarms are active and

require attention.

15. Make certain any filter, dryer, or user block and bypass

valves are in the correct positions.

16. The system is ready to go on line and dry the process air.

Normal Settings

Heat Control 400

Dew point Demand - 50

High Humidity - 10

Heatless Regenerative Desiccant Air Dryer | AHLD Series

19

AIRCEL PROGRAMMABLE CONTROLLER (APC)

System Navigation

System display shows the dryer operations and provides the user the ability to change certain dryer settings.

Left Arrow

Key

Down Arrow

Key

OK Key * Key

Red LED 1:

Common alarm

light

• Standard alarms:

EMS humidity

probe failure and

drain fault

• Optional alarms:

High humidity,

dew point probe

failure and failure

to shift

Red LED 2: Energy

Savings Active

Light

Up Arrow

ALT key

Right Arrow Key

Text Display

Delete Key

Escape Key

AHLD Series | Heatless Regenerative Desiccant Air Dryer

20

AIRCEL PROGRAMMABLE CONTROLLER (APC)

Dryer Operations

STEP ONE: Select Vessel 2 Depressurizing (0 - 5 seconds)

Vessel 2 (T2) purge exhaust pilot solenoid valve is energized,

supplying control air to slowly open the purge exhaust valve

(V4), depressurizing vessel 2 (T2).

Simultaneously, the inlet valves V1 and V2 shift positions with

a pneumatic signal from vessel 2 (T2) purge exhaust pilot

solenoid valve to the inlet tower selector pneumatic pilot valve.

This action supplies a pneumatic signal to the inlet valves to

open valve (V1) and close valve (V2), directing the inlet air to

vessel 1 (T1) to dry the air.

The air flows up through the desiccant bed and exits outlet

valve (V5) to the outlet particulate filter. The air then moves

down the line, to the customer dry process air system.

STEP TWO: Vessel 2 Regenerating (6 - 240 seconds)

Vessel 2 (T2) is regenerating, Vessel 2 (T2) purge exhaust valve

(V4) is still open, Vessel 1 (T1) is drying the inlet air.

A small portion of dry outlet air from Vessel 1 (T1) (15% average

based on standard design capacity of 100 psig, 100°F ambient

air and PDP of -40°F) is taken through a small orifice in the

outlet line and used to regenerate the desiccant bed in Vessel 2

(T2) until 240 seconds has been reached.

The timer on this step counts to 240 seconds (4-minutes).

A warning sign will flash in the upper right hand portion of the

screen and a red LED alarm light will flash on the PLC display

for any alarm. To view alarms, press the left arrow once from

the main screen.

The screen also displays the relative humidity reading and dew

point (optional).

Heatless Regenerative Desiccant Air Dryer | AHLD Series

21

AIRCEL PROGRAMMABLE CONTROLLER (APC)

Dryer Operations, Cont.

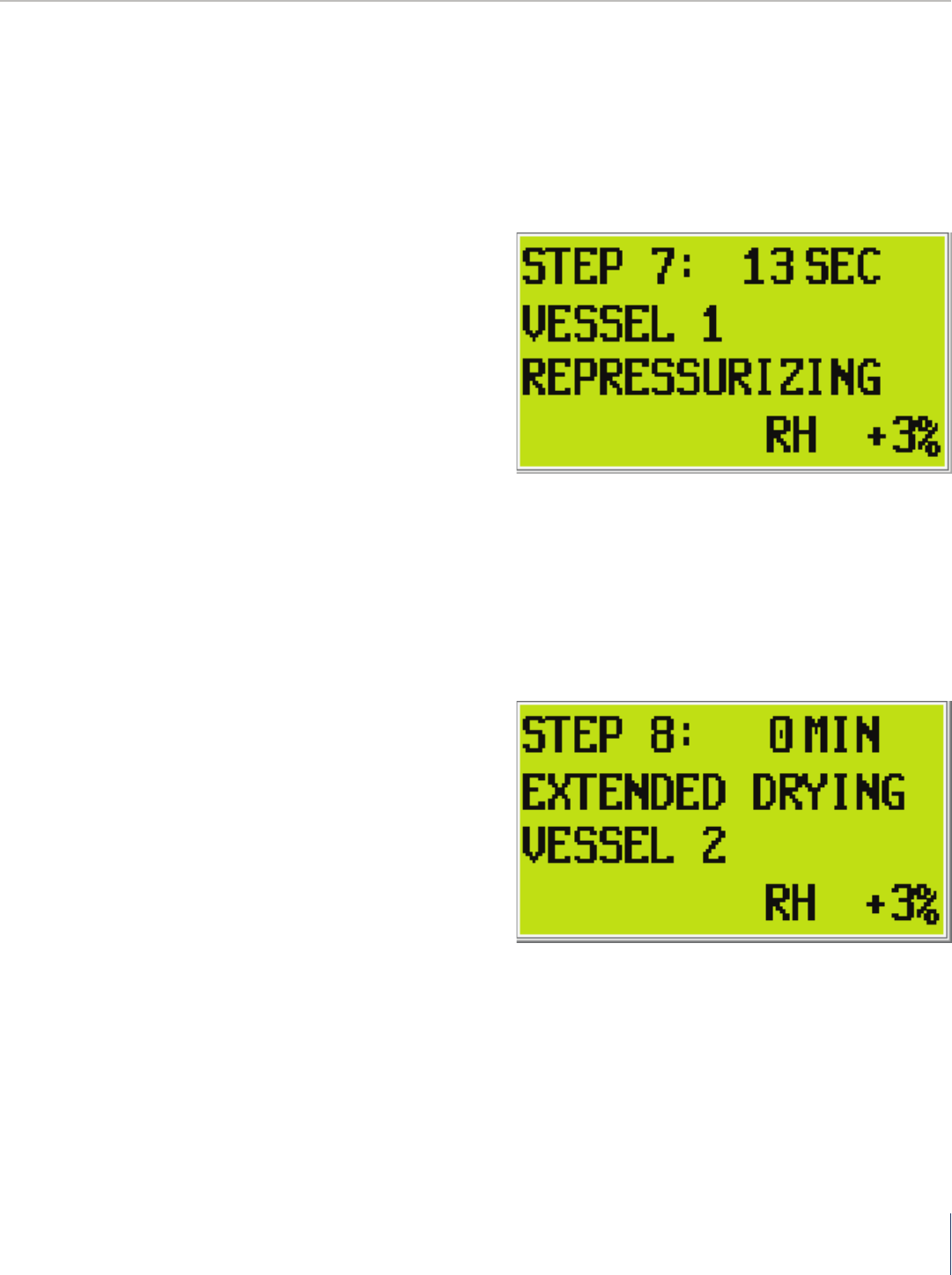

STEP THREE: Opens Vessel 2 Repressurizing (241 - 300

seconds)

Vessel 2 (T2) purge exhaust pilot solenoid valve will de-energize,

causing Vessel 2 (T2) purge exhaust valve (V4) to close,

respressurizing Vessel 2 (T2).

The inlet tower selector pneumatic pilot valve maintains the

inlet valve (V1 & V2) positions.

STEP FOUR: Vessel 1 Extended Drying

A few seconds before the end of repressurization, the

integrated Energy Management Purge Reduction System’s

moisture sensor determines the tower moisture load. If Vessel

1 (T1)’s moisture load is low enough, the tower will continue to

dry for an extended drying period until the moisture load has

reached a set high level or an additional 30 minutes, whichever

comes first. After 30 minutes, the unit will switch and continue

normal operation until the next extended savings step.

At the start of each extended savings step, the PLC checks for

faults, EMS relative humidity sensor value, and high outlet dew

point setting (optional) to ensure if the dryer needs to continue

drying. If so, the dryer will go into extended drying.

This feature reduces the overall purge consumption, saving

energy and money.

Note: If the dryer needs to continue to the next step to

regenerate based on humidity, the extended savings step

4 will be skipped.

AHLD Series | Heatless Regenerative Desiccant Air Dryer

22

AIRCEL PROGRAMMABLE CONTROLLER (APC)

Dryer Operations, Cont.

STEP FIVE: Vessel 1 Depressurizing (0 - 5 seconds)

Vessel (T1) purge exhaust pilot solenoid valve is energized,

supplying control air to the purge exhaust valve (V4),

depressurizing vessel 1 (T1).

Simultaneously, the inlet valves V2 and V1 shift positions with

a pneumatic signal from vessel 1’s (T1) purge exhaust pilot

solenoid valve to the inlet tower selector pneumatic pilot valve.

This supplies a pneumatic signal to the inlet valves to open

valve (V2) and close valve (V1), directing the inlet air to vessel

2 (T2) to begin drying the air. The air flows up through the

desiccant bed and exits to the outlet valve (V6) to the outlet

particulate filter and through to downstream equipment.

STEP SIX: Vessel 1 Regenerating (6 - 240 seconds)

Vessel 1 (T1) is regenerating, Vessel 1 (T1) purge exhaust valve

(V3) is still open, Vessel 2 (T2) is drying the inlet air.

A small portion of dry outlet air from Vessel 2 (T2) (15% average

based on standard design capacity of 100 psig, 100°F ambient

air and PDP of -40°F) is taken through a small orifice in the

outlet line and used to regenerate the desiccant bed in Vessel 1

(T1) until 240 seconds has been reached.

The timer on this step counts to 240 seconds (4-minutes).

Heatless Regenerative Desiccant Air Dryer | AHLD Series

23

AIRCEL PROGRAMMABLE CONTROLLER (APC)

Dryer Operations, Cont.

STEP SEVEN: Vessel 1 Repressurizing (241 - 300 seconds)

Vessel 1 (T1) purge exhaust pilot solenoid valve will de-energize,

causing Vessel 1 (T1) purge exhaust valve (V3) to close,

respressurizing Vessel 1 (T1).

The inlet tower selector pneumatic pilot valve maintains the

inlet valve (V1 & V2) positions.

STEP EIGHT: Vessel 2 Extended Drying

A few seconds before the end of repressurization, the

integrated Energy Management Purge Reduction System’s

moisture sensor determines the tower moisture load. If Vessel

2 (T2)’s moisture load is low enough, the tower will continue to

dry for an extended drying period until the moisture load has

reached a set high level or an additional 30 minutes, whichever

comes first. After 30 minutes, the unit will switch and continue

normal operation until the next extended savings step.

At the start of each extended savings step, the PLC checks for

faults, EMS relative humidity sensor value, and high outlet dew

point setting (optional) to ensure if the dryer needs to continue

drying. If so, the dryer will go into extended drying.

This feature reduces the overall purge consumption, saving

energy and money.

AHLD Series | Heatless Regenerative Desiccant Air Dryer

24

AIRCEL PROGRAMMABLE CONTROLLER (APC)

Main Screen Navigation

Control Menu Navigation

LEFT/RIGHT

LEFT/RIGHT

ALARM

SCREEN

MAIN

SCREEN

CONTROL

MENU

SETTINGS

MENU

LEFT/RIGHT

LEFT/RIGHT

Heatless Regenerative Desiccant Air Dryer | AHLD Series

25

Control Menu Operation

Settings Screen Operation

CONTROL

MENU

AIRCEL PROGRAMMABLE CONTROLLER (APC)

• Push OK to engage the menu

• Scroll to the desired selection and push OK

Settings Screen: For use with optional dew point display and high

humidity alarm

• To engage, push OK then scroll to the desired set point to be

changed.

• Push OK on the set point to be changed and use the up or down

arros to change the set point.

• Push OK to complete the change and ESC to de-select the screen.

Push ESC again to exit to the main screen or use the left or right

arrows to scroll to the next screen.

AHLD Series | Heatless Regenerative Desiccant Air Dryer

26

AIRCEL PROGRAMMABLE CONTROLLER (APC)

Time Control Main Navigation

This time cycle control menu allows the user to choose between a 10 minute standard time cycle and a shorter 5 minute cycle

for lower dew point option.

LEFT/RIGHT

SETTINGS

MENU

ANALOG

SCREEN

LEFT/RIGHT

Time Control Menu Operation

• To change the time cycle, push OK then scroll to the time cycle to

be selected. Push OK then push ESC.

• When changes are complete, push ESC to exit changes. Push ESC

again to return to the main screen.

Heatless Regenerative Desiccant Air Dryer | AHLD Series

27

Analog Screen Navigation

The analog screen simply displays the analog output signals.

Hours of Operation Screen Navigation

The hours of operation screen gives the user the amount of run time as well as the total amount of hours saved with the energy

management system.

LEFT/RIGHT

LEFT/RIGHT

TIME CONTROL

SCREEN

ANALOG

SCREEN

HOURS OF

OPERATION

ALARM

SCREEN

LEFT/RIGHT

LEFT/RIGHT

AIRCEL PROGRAMMABLE CONTROLLER (APC)

AHLD Series | Heatless Regenerative Desiccant Air Dryer

28

ALARM POP-UPS

• No Alarm: Alarm has been corrected

• Bad Probe: The EMS sensor has reached an out of range signal (check sensor and cable)

• High Outlet Dew Point (Option): Dew point has reached set point (check desiccant, pre-filters, control system)

• Failure to Shift (Option): Tower did not properly repressurize

AIRCEL PROGRAMMABLE CONTROLLER (APC)

Alarm Screen Navigation

LEFT/RIGHT

HOURS OF

OPERATION

MAIN MENU

LEFT/RIGHT

Heatless Regenerative Desiccant Air Dryer | AHLD Series

29

Alarm Pop-Up Screens

AIRCEL PROGRAMMABLE CONTROLLER (APC)

No Alarm: The normally closed state of the common alarm relay.

Drain Fault: Shows when the relative humidity (EMS) probe is out of range. This can be

either high out of range or low out of range. When this happens, the signal has either

been lost or the sensor may need to be replaced.

Bad RH Probe: Shows when the relative humidity (EMS) probe is out of range. This

can be either high out of range or low out of range. When this happens, the signal has

either been lost or the sensor may need to be replaced.

High Humidity Alarm: Alarm that is visible when the dew point is higher than the

set point. The set point for the high humidity alarm can be changed but it is not

recommended.

Bad Dew-P Probe: Alarm for the dew point sensor probe out of range. The out of range

can be either high or low. This can be either a complete loss of signal/voltage, the

resistor can be disconnected or the sensor may need to be calibrated.

The FTS Alarm (Failure-to-Shift): Alarm present when a vessel does not depressurize

correctly or if a vessel that is to be drying does not have pressure at or above a certain

set pressure.

AHLD Series | Heatless Regenerative Desiccant Air Dryer

30

TROUBLESHOOTING TABLE

Problem Probable Cause Remedy

High Dew Point

High inlet air ow Reduce inlet air ow

Inlet air temperature above design spec Reduce inlet air temperature to design spec

Poor pre-ltration Check pre-lter element, replace if needed

Inlet air pressure below design spec Increase pressure to the dryer

Desiccant contaminated Replace desiccant

Purge ow orice in the outlet APV valve may

be clogged

Dismantle outlet APV valve, and clean out the orice

Back pressure in regenerating chambers Muers are clogged, install new muers

Exhaust valve(s) not fully opening or closing

Check pilot valve and pilot air supply, dismantle and clean

exhaust valve, check ow control valve attached to purge

exhaust valve actuator may not be adjusted properly (should

be adjusted so exhaust valve opens within a 8-12 minute

time period)

APV valve leaking Dismantle and clean, replace seals and piston if needed

No input power Check that dryer is on with correct voltage

Controller failure Check, replace if needed

High Pressure

Drop

Low inlet pressure Increase inlet pressure to design pressure

Desiccant dusting High inlet ow velocities due to high ow

Inlet pre-lter dirty Inspect and replace as needed

High inlet ow rate Reduce inlet ow rate to meet dryer spec

Outlet lter dirty Inspect and replace as needed

Desiccant diuser screens clogged Inspect and clean as needed

High Back Pressure

in Regenerating

Tower

Purge muer clogged Clean and replace if needed

Desiccant diuser screens clogged Inspect and clean as needed

Restrictive purge exhaust piping Clean and replace with larger pipe if required

Heatless Regenerative Desiccant Air Dryer | AHLD Series

31

TROUBLESHOOTING TABLE

Problem Probable Cause Remedy

Dryer Fails to Shift

Towers

Exhaust valve(s) not functioning

Check pilot valve and pilot air supply, dismantle and clean

exhaust valve. Check ow control valve attached to purge

exhaust valve actuator may not be adjusted properly (should

be adjusted so exhaust valve opens within a 8-12 second

time period).

No input power Check that dryer is on with correct voltage

Controller failure Check, replace if needed

Pilot air supply restricted Check pilot lter, and pilot tubing restriction

Purge ow orice in the outlet APV valve may

be clogged

Dismantle outlet APV valve, and clean out the orice

Input APV valve malfunction Dismantle, clean, and reinstall

Outlet APV valve malfunction Dismantle, clean, and reinstall

Purge Failure

Purge muer clogged Remove and clean, replace if needed

Purge ow orice in the outlet APV valve may

be clogged

Dismantle outlet APV valve, and clean out the orice

Controller failure Check, replace if needed

Exhaust valve(s) not functioning

Check pilot valve and pilot air supply, dismantle and clean

exhaust valve purge exhaust valve actuator may not be

adjusted properly (should be adjusted so exhaust valve

opens within an 8-12 second time period). Check control

system.

Pressurization

Failure

Purge ow orice in the outlet APV valve may

be clogged

Reduce inlet ow rate to meet dryer spec

Exhaust valve(s) not functioning

Check pilot valve and pilot air supply, dismantle and clean

exhaust valve purge exhaust valve actuator may not be

AHLD Series | Heatless Regenerative Desiccant Air Dryer

32

2

.

Composition/information on ingredients

CAS Number

Content (W/W)

Chemical name

1333-84-2

>= 94.0 - <= 100.0 %

Aluminum oxide (Al2O3), hydrate

3

.

Hazard identification

Emergency overview

CAUTION: MAY CAUSE EYE, SKIN AND RESPIRATORY TRACT IRRITATION

.

May cause difficulty breathing

.

Prolonged or repeated contact may result in dermatitis

.

Contact with the eyes or skin may cause mechanical irritation

.

Contains material which may indicate/cause the possibility of sensory and pulmonary irritation

.

Avoid contact with the skin, eyes and clothing

.

Avoid inhalation of dusts

.

Use with local exhaust ventilation

.

Wear a NIOSH-certified (or equivalent) particulate respirator

.

Wear safety glasses with side-shields

.

Wear chemical resistant protective gloves

.

Wear protective clothing

.

Eye wash fountains and safety showers must be easily accessible

.

Potential health effects

Primary routes of exposure

Routes of entry for solids and liquids include eye and skin contact, ingestion and inhalation

. Routes of entry for

gases include inhalation and eye contact

.

Skin contact may be a route of entry for liquified gases

.

4

.

First-aid measures

If inhaled:

Keep patient calm, remove to fresh air

.

If necessary, give oxygen

.

If not breathing, give artificial respiration

.

Seek medical attention if necessary

.

Page: 1/5

(30286124/MDS_GEN_US/EN)

Company

BASF CORPORATION

100 Campus Drive

Florham Park, NJ 07932, USA

Safety data sheet

F200

Revision date : 2009/12/04

Version: 3.0

1

.

Substance/preparation and company identification

24 Hour Emergency Response Information

CHEMTREC: 1-800-424-9300

BASF HOTLINE: 1-800-832-HELP

APPENDIX

Desiccant Material Safety Data Sheet

Heatless Regenerative Desiccant Air Dryer | AHLD Series

33

6

.

Accidental release measures

Cleanup:

Vacuum up spilled product

.

Place into suitable container for disposal

.

7

.

Handling and storage

Handling

General advice:

Avoid dust formation in confined areas

.

Avoid contact with the skin, eyes and clothing

.

Ensure adequate

ventilation

.

Storage

General advice:

Keep container tightly closed in a cool, well-ventilated place

.

Storage stability:

Keep container dry.

8

.

Exposure controls and personal protection

Components with workplace control parameters

Aluminum oxide (Al2O3),

OSHA

PEL 5 mg/m3 Respirable fraction ; PEL 15 mg/m3 Total

hydrate

dust ;

ACGIH

TWA value 1 mg/m3 Respirable fraction ;

Safety data sheet

F200

Revision date : 2008/12/04

Version: 3.0

Page: 2/5

(30286124/MDS_GEN_US/EN)

If on skin:

After contact with skin, wash immediately with plenty of water and soap

.

Consult a doctor if skin irritation

persists

.

If in eyes:

In case of contact with the eyes, rinse immediately for at least 15 minutes with plenty of water

.

Immediate

medical attention required

.

If swallowed:

No hazards anticipated

.

If large quantities are ingested, seek medical advice.

5

.

Fire-fighting measures

Flash point:

Additional information:

Use extinguishing measures to suit surroundings

.

Hazards during fire-fighting:

No particular hazards known

.

Non-flammable.

Protective equipment for fire-fighting:

Wear self-contained breathing apparatus and chemical-protective clothing

.

NFPA Hazard codes:

Health : 0 Fire: 0

Reactivity: 1

Special:

APPENDIX

Desiccant Material Safety Data Sheet

AHLD Series | Heatless Regenerative Desiccant Air Dryer

34

APPENDIX

Desiccant Material Safety Data Sheet

Advice on system design:

Provide local exhaust ventilation to control dust

.

Provide local exhaust ventilation to maintain recommended

P.E.L

.

Personal protective equipment

Respiratory protection:

Wear a NIOSH-certified (or equivalent) particulate respirator

.

Observe OSHA regulations for respirator use (29

CFR 1910.134)

.

Wear appropriate certified respirator when exposure limits may be exceeded

.

Hand protection:

Wear chemical resistant protective gloves., Consult with glove manufacturer for testing data

.

Eye protection:

Safety glasses with side-shields

.

Body protection:

Body protection must be chosen based on level of activity and exposure

.

9

.

Physical and chemical properties

Safety data sheet

F200

Revision date : 2008/12/04

Version: 3.0

Page: 3/5

(30286124/MDS_GEN_US/EN)

Form:

Odour:

Colour:

pH value:

Melting point:

Boiling point:

Vapour pressure:

Density:

Bulk density:

Partitioning coefficient

n-octanol/water (log Pow):

Viscosity, dynamic:

Solubility in water:

10

.

Stability and reactivity

powder, granules, pellets, balls

odourless

off-white

9.4 - 10.1

2,050 °C

No data available

.

No data available

.

No data available

.

approx

.

650 kg/m3

38.0 - 52 lb/ft3

( 68 °F)

No data available

.

No data available

.

insoluble

Substances to avoid:

water

Hazardous reactions:

The product is chemically stable

.

Addition of water leads to increase in temperature

.

11

.

Toxicological information

Oral:

Information on: Aluminum oxide

LD50/rat: > 5,000 mg/kg (OECD Guideline 401)

----------------------------------

Heatless Regenerative Desiccant Air Dryer | AHLD Series

35

APPENDIX

Desiccant Material Safety Data Sheet

Information on: Aluminum oxide

Acute and prolonged toxicity to fish:

DIN 38412 Part 15 static

golden orfe/LC50 (96 h): > 500 mg/l

The product has not been tested

.

The statement has been derived from products of a similar structure and

composition

.

----------------------------------

Information on: Aluminum oxide

Acute toxicity to aquatic invertebrates:

OECD Guideline 202, part 1 static

Daphnia magna (48 h): > 100 mg/l

----------------------------------

13

.

Disposal considerations

Waste disposal of substance:

Dispose of in accordance with local authority regulations

.

Check for possible recycling

.

Disposal requirements are dependent on the hazard classification and will vary by location and the type of

disposal selected

.

All waste materials should be reviewed to determine the applicable hazards (testing may be necessary)

.

14

.

Transport information

Land transport

USDOT

Not classified as a dangerous good under transport regulations

Sea transport

IMDG

Not classified as a dangerous good under transport regulations

Air transport

IATA/ICAO

Not classified as a dangerous good under transport regulations

15

.

Regulatory information

Federal Regulations

Safety data sheet

F200

Revision date : 2008/12/04

Version: 3.0

Skin irritation:

Information on: Aluminum oxide

rabbit: non-irritant (OECD Guideline 404)

----------------------------------

12

.

Ecological information

Page: 4/5

(30286124/MDS_GEN_US/EN)

AHLD Series | Heatless Regenerative Desiccant Air Dryer

36

APPENDIX

Desiccant Material Safety Data Sheet

HMIS uses a numbering scale ranging from 0 to 4 to indicate the degree of hazard

.

A value of zero means that the substance

possesses essentially no hazard; a rating of four indicates high hazard

.

Local contact information

IMPORTANT: WHILE THE DESCRIPTIONS, DESIGNS, DATA AND INFORMATION CONTAINED HEREIN

ARE PRESENTED IN GOOD FAITH AND BELIEVED TO BE ACCURATE , IT IS PROVIDED FOR YOUR

GUIDANCE ONLY

.

BECAUSE MANY FACTORS MAY AFFECT PROCESSING OR APPLICATION/USE, WE

RECOMMEND THAT YOU MAKE TESTS TO DETERMINE THE SUITABILITY OF A PRODUCT FOR YOUR

PARTICULAR PURPOSE PRIOR TO USE

.

NO WARRANTIES OF ANY KIND, EITHER EXPRESSED OR

IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE MADE REGARDING PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION

SET FORTH, OR THAT THE PRODUCTS, DESIGNS, DATA OR INFORMATION MAY BE USED WITHOUT

INFRINGING THE INTELLECTUAL PROPERTY RIGHTS OF OTHERS

.

IN NO CASE SHALL THE

DESCRIPTIONS, INFORMATION, DATA OR DESIGNS PROVIDED BE CONSIDERED A PART OF OUR

TERMS AND CONDITIONS OF SALE

.

FURTHER, YOU EXPRESSLY UNDERSTAND AND AGREE THAT

THE DESCRIPTIONS, DESIGNS, DATA, AND INFORMATION FURNISHED BY BASF HEREUNDER ARE

GIVEN GRATIS AND BASF ASSUMES NO OBLIGATION OR LIABILITY FOR THE DESCRIPTION,

DESIGNS, DATA AND INFORMATION GIVEN OR RESULTS OBTAINED, ALL SUCH BEING GIVEN AND

ACCEPTED AT YOUR RISK

.

END OF DATA SHEET

Safety data sheet

F200

Revision date : 2008/12/04

Version: 3.0

Registration status:

TSCA, US

OSHA hazard category:

Page: 5/5

(30286124/MDS_GEN_US/EN)

State RTK

MA, NJ, PA

released / listed

ACGIH TLV established

SARA hazard categories (EPCRA 311/312):

Acute

SARA 313:

CAS Number

1333-84-2

State regulations

State RTK

CAS Number

1333-84-2

Chemical name

Aluminum oxide (Al2O3), hydrate

Chemical name

Aluminum oxide (Al2O3), hydrate

16

.

Other information

HMIS III rating

Health: 1

Flammability: 0 Physical hazard:

1

Heatless Regenerative Desiccant Air Dryer | AHLD Series

37

APPENDIX

Electrical Schematic Drawings

AHLD Series | Heatless Regenerative Desiccant Air Dryer

38

APPENDIX

Main Power & PLC Input Drawings

Heatless Regenerative Desiccant Air Dryer | AHLD Series

39

APPENDIX

PLC Outlet & Sensor Drawings

AHLD Series | Heatless Regenerative Desiccant Air Dryer

40

APPENDIX

Back Panel Drawings

ITEMNUMBER PARTNUMBER DESCRIPTION QTY

1 AG3197201 BACKPLATEFITS14x 12 1

2 AG3948924 POWERSUPPLY,24VDC 1

3 AG3934769 POWERSUPPLY,5VDC 1

4 AG3251901 ANCHOR,SCREWEND,GRAY 6

6 AG3253101 TERMINALBLOCK,GRAY,J4 2

7 AG3253001 TERMINALBLK,GREEN/YELLOW ,J4 1

8 AG3933672 TERMINALBLOCK,BLUE,J3 4

9 AG3933345 TERMINALBLK,GRAY,J3 30

10 AG3948856 RELAY,SCREWTYPETERMINAL,SPDT 1

11 AG3182201 DUCT,WHITE,NARROWSLOT,1"X2" 3

12 AG3480590 COVER,WHITEDUCT,1" 3

13 AG3933346 TERMINALBLK,GREEN/YELLOW,J3 3

14 AG3948855 RELAY,SCREWTYPETERMINAL,DPDT 3

Heatless Regenerative Desiccant Air Dryer | AHLD Series

41

APPENDIX

Enclosure Layout Drawings

ITEMNUMBER QTY PARTNUMBER DESCRIPTION

50 1 AG3934778 EZDDISPLAY

51 1 AG3934775 EZDPROCESSOR

52 1 AG3934777 EZDI/O MODULE

54 1 AG3935996 ENCLOSURE,MODIFIED,14x12

55 1 AG3935091 SWITCH,PUSHBUTTON, ROUND

56 1 AG3935094 CONTACTBLOCKFORPUSHBUTTON

58 4 AG3935998 LIGHT,BLUE,6MM

59 2 AG3288701 MYERSHUBS

60 2 AG3342801 1/2XCLOSECONDUITNIPPLES

62 2 AG3101501 VA LVE,SOLENOID,3WAY,NEMA4

AHLD Series | Heatless Regenerative Desiccant Air Dryer

42

APPENDIX

Electrical Part Drawings

AHLDE‐SERIESELECTRICALDRAWING,AIRCEL

PROGRAMMABLE

CONTROLLER,NEMA‐4WITHENERGY

MANAGEMENT.

StockNumber StockDescription Quantity Spare?

AG3934778 EZDCONTROLLER,PROCESSOR 1 Y

AG3934775 EZDCONTROLLER,12DCINPUTS 1 Y

AG3934777 EZDCONTROLLER,CPU 1 Y

AG3935996 ENCLOSURE,MODIFIED,14X12 1 N

AG3935091 SWITCH,PUSHBUTTON,ROUND 1 Y

AG3935094 SWITCH,CONTACTBLOCK,FORALL 1 Y

AG3935095 LIGHT, FOR800BSWITCH,LED 1 Y

AG3935096 LENSFORPUSHBUTTON,GREEN 1 Y

AG3935998 LIGHT,PILOT,115V,8MM,BLUE 4 Y

AG3288701 HUB,MYERS,1/2" 2 Y

AG3342801 NIPPLE,CONDUIT ,1/2"XCLOSE, 2 N

AG3481168 STRAINRELIEF,3/8" 3 N

AG3481158 LOCKNUT,3/8" 3 N

AG3481159 RINGSEAL,3/8" 3 N

AG3948855 RELAY,SCREWTYPETERMINAL,DPDT 3 Y

AG3197201 PANE L,BACKPLATE,FITS14x12 1 N

AG3948924 POWERSUPPLY,24VDC 1 Y

AG3934769 POWERSUPPLY,5VDC 1 Y

AG3251901 ANCHOR,SCREWEN D,GRAY 6 N

AG3253101 TERMINALBLOCK,GRAY,J4 2 N

AG3253001 TERMINALBLOCK,GREEN/YELLOW,J4 1 N

AG3933672 TERMINALBLOCK ,BLU,J3 4 N

AG3933345 TERMINALBLOCK,GRAY,J3 30 N

AG3948856 RELAY,SCREWTYPETERMINAL,SPDT 1 Y

AG3182201 DUCT,WHITE,NARROWSLOT,1x2 3 N

AG3101501 VALVE,SOLENOID,3WAY,NEMA4,1/4" 2 Y

AG3933346 TERMINALBLK,GREEN/YELLOW,J3 3 N

AG3480590 COVER,WHITEDUC T,1" 3 N

AG3481460 CORD,SJEEO W,18/3 10 N

AG3480463 WIRE#18,BLUE 80 N

AG3480947 WIRE#18,RED 98 N

AG3480948 WIRE#18,WHITE 17 N

AG3480991 WIRE#18,WHITE/BLUE 9.5 N

AG3373901 WIRE#16,ORANGE 6 N

AG3372301 WIRE#16,GREEN 12 N

Heatless Regenerative Desiccant Air Dryer | AHLD Series

43

SERVICE NOTES

DATE SERVICE PERFORMED NOTES

AHLD Series | Heatless Regenerative Desiccant Air Dryer

44

SERVICE NOTES

DATE SERVICE PERFORMED NOTES

Heatless Regenerative Desiccant Air Dryer | AHLD Series

45

SERVICE NOTES

DATE SERVICE PERFORMED NOTES

AHLD Series | Heatless Regenerative Desiccant Air Dryer

46

SERVICE NOTES

DATE SERVICE PERFORMED NOTES

Heatless Regenerative Desiccant Air Dryer | AHLD Series

47

WARRANTY

Desiccant Air Dryers

(1 Year Limited Warranty Coverage)

Standard desiccant air dyrers come with a limited one year

warranty covering parts and labor.

NOTE: Any unit shipped to us without prior return

authorization will be refused.

WARRANTY PARTS COVERAGE

• Exhaust valves (all models)

• Wafer check valves (800 - 5,000 scfm models)

• Heater

• Blower

• Control board (all heatless models)

• Programmable controller (all heat regenerative models)

• Automatic pisto valves

• Control solenoids

• Re-pressurization valves

• Depressurization valves

• Electrical components (temperature and over-temperature

controllers)

• Instrumentation (air and dierential pressure gauges,

temperature gauges)

SERVICE COVERAGE

• Parts supplied by us to dealer, authorized service repair

center, or job site (end user). See note 5 on page 6.

• Labor provided by us, dealer, authorized service repair

center, or factory.

Zero Loss Drains

(1 Year Limited Warranty Coverage)

COVERAGE

• Parts supplied by us to dealer, authorized service repair

center, or job site (end user). See note 5 on page 6.

• Labor is not covered by our warranty. Customer is

responsible for all labor.

NOTES:

1. Aircel reserves the right to require units to be shipped

back to the factory for proper repair if it deems necessary.

We will make return freight arrangements in this instance.

Aircel warranty will only cover freight charges for

shipments within the continental United States.

2. Warranty does not cover the removal & installation of a

dryer(s) or parts within its warranty period or beyond.

3. Desiccant is not covered under warranty. The average

life expectancy of desiccant is 3 to 5 years when proper

maintenance is performed.

Aircel, LLC.

323 Crisp Circle

Maryville, TN 37801

Parts and Service

For genuine Aircel replacement parts, call:

800.767.4599

For faster service, please have unit’s

model and serial number, part number, or

description.

AircelDryers.com