CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

MSFC-SPEC-3679

National Aeronautics and REVISION A

Space Administration EFFECTIVE DATE: October 22, 2018

George C. Marshall Space Flight Center

Marshall Space Flight Center, Alabama 35812

EM30

MSFC TECHNICAL STANDARD

PROCESS SPECIFICATION -

WELDING AEROSPACE

HARDWARE

Approved for Public Release; Distribution is Unlimited

MEASUREMENT SYSTEM

ENGLISH/METRIC (SI)

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 2 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

DOCUMENT HISTORY LOG

Status (Baseline/

Revision/

Cancelled)

Document

Revision

Effective Date

Description

Baseline

-

10/11/2012

Baseline Release; document authorized through

MPDMS. [Baselined by Upper Stage Element

Control Board Directive CE4-01-0239, (PCN

CE001107, CR CLV-US-0481).]

Revision

A

10/22/2018

Added section 1.3 – Units of Measurement. Moved

sections 1.4 – Safety and 1.5 – Specific Process

Weld Requirements to section 3.0 – Requirements.

Added CGA specifications and removed cancelled

gas specifications from section 2.0 – Applicable

Standards and Documents. Moved Acronyms and

Definitions from section 3.0 to Appendix I –

Acronyms and Definitions. Removed section 5.1.5

– Weld Equipment Requalification and added

section 5.1.10 – Weld Equipment Modification.

Clarified section 7.3.2 – Weld Testing

Methodology. Moved section 9.5.2.b – Equipment

Fluctuations to Section 5.1 – Welding Equipment.

Reformatted Tables in Appendix A.

Clarified intent of Confidence Weld Requirements

and moved sections within 7.3 for a logical

approach.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 3 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

TABLE OF CONTENTS

PARAGRAPH PAGE

SCOPE ................................................................................................................................... 8

Purpose ................................................................................................................................ 8

Applicability ....................................................................................................................... 8

Units of Measurement ......................................................................................................... 9

Tailoring .............................................................................................................................. 9

APPLICABLE DOCUMENTS .......................................................................................... 10

Applicable Standards and Documents .............................................................................. 10

Reference Documents ....................................................................................................... 12

Order of Precedence .......................................................................................................... 12

REQUIREMENTS .............................................................................................................. 13

Safety ................................................................................................................................ 13

Specific Process Weld Requirements ............................................................................... 13

JOINT CLASSES................................................................................................................ 14

Inspection Criteria ............................................................................................................. 14

Joint Classifications .......................................................................................................... 14

EQUIPMENT ...................................................................................................................... 15

Welding Equipment .......................................................................................................... 15

Tooling and Fixtures ......................................................................................................... 16

Electron Beam Welding .................................................................................................... 17

MATERIALS ...................................................................................................................... 18

Base Metals ....................................................................................................................... 18

Filler Metals ...................................................................................................................... 18

Shielding Gas .................................................................................................................... 18

Tungsten Electrodes .......................................................................................................... 19

FSW Pin Tools .................................................................................................................. 19

Anvils and Plug Weld Backing Material .......................................................................... 19

Friction Plugs .................................................................................................................... 19

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 4 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

WELDER PERFORMANCE AND WELD PROCEDURE QUALIFICATION ......... 20

Welder Performance Qualification ................................................................................... 20

Weld Procedure Specification........................................................................................... 20

Procedure Qualification Records ...................................................................................... 22

Records ............................................................................................................................. 24

PREWELD OPERATIONS ............................................................................................... 25

Weld Joint Design ............................................................................................................. 25

Preweld Cleaning .............................................................................................................. 25

Preweld Joint Fit-up .......................................................................................................... 26

Weld Start and Run-Off Tabs ........................................................................................... 27

Laser and Electron Beam-to-Joint Alignment .................................................................. 27

PRODUCTION WELDING .............................................................................................. 28

Equipment Operational Readiness Check ......................................................................... 28

Temperature Control. ........................................................................................................ 28

Tack Welding .................................................................................................................... 28

Welding Techniques ......................................................................................................... 28

Welding Procedure............................................................................................................ 29

POSTWELD OPERATION ............................................................................................... 30

The Weldment ................................................................................................................... 30

General Workmanship Requirements ............................................................................... 30

Dimensional Requirements ............................................................................................... 30

Weldment Straightening ................................................................................................... 33

Postweld Heat Treatment Requirements ........................................................................... 34

Weldment Quality Requirements ...................................................................................... 34

Repair Welding ................................................................................................................. 34

Material Review Board ..................................................................................................... 35

VERIFICATION................................................................................................................. 36

General .............................................................................................................................. 36

Postweld Inspection .......................................................................................................... 36

Records ............................................................................................................................. 37

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 5 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

LIST OF APPENDICES

Appendix Page

Appendix A Procedure Qualification Weld Strength Requirements ................................................ 39

Appendix B Weld Joint Dimensional Requirements ........................................................................ 44

Appendix C Weld Nugget Dimensional Requirements .................................................................... 46

Appendix D Weld Quality Requirements ......................................................................................... 65

Appendix E Weld Procedure Specification Information .................................................................. 73

Appendix F Recommended Weld Filler Metals ............................................................................... 75

Appendix G Preweld and Postweld Cleaning Methods .................................................................... 82

Appendix H Reference Documents .................................................................................................. 83

Appendix I Acronyms and Definitions ............................................................................................. 85

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 6 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

LIST OF TABLES

Table Page

Table I. Minimum Inspection Requirements .................................................................................... 14

Table II. WPS Allowable Qualified Thickness Range ..................................................................... 20

Table III. GTAW Process Butt Weld Ultimate Tensile Strength Requirements .............................. 40

Table IV. VPPA Process Butt Weld Ultimate Tensile Strength Requirements ................................ 41

Table V. FSW Process Butt Weld Ultimate Tensile Strength Requirements ................................... 41

Table VI. Close-out FPW in FSW Process Ultimate Tensile Strength Requirements ..................... 42

Table VII. Fusion Butt Weld Ultimate Tensile Strength Requirements for Superalloys ................. 43

Table VIII. Fusion Butt Weld Ultimate Tensile Strength Requirements for Titanium Alloys ......... 43

Table IX. Fusion Butt Weld Ultimate Tensile Strength Requirements for Stainless Steel Alloys ... 43

Table X. Preweld Joint Fit-up Requirements .................................................................................... 44

Table XI. Postweld Joint Fit-up Requirements ................................................................................. 45

Table XII. Dimensional Requirements for Butt Welds – Fusion

1

.................................................... 46

Table XIII. Dimensional Characteristics of Aluminum Alloy Butt Welds ...................................... 50

Table XIV. Dimensional Requirements ............................................................................................ 52

Table XV. Weld Surface and Volumetric Acceptance Criteria – Aluminum Alloys ....................... 65

Table XVI. Surface and Volumetric Acceptance Criteria – Steels, Heat Resistant Alloys .............. 71

Table XVII. Weld Surface and Volumetric Acceptance Criteria – Titanium Alloys ....................... 72

Table XVIII. Recommended Parameters to be Recorded in a WPS ................................................. 73

Table XIX. Filler Alloys Recommended for Aluminum Alloys and Combinations ........................ 75

Table XX. Filler Alloys Recommended for Carbon and Low Alloy Steels and Combinations ....... 76

Table XXI. Filler Alloys Recommended for Stainless Steels and Combinations ............................ 77

Table XXII. Filler Alloys Recommended for Nickel- and Cobalt-Base Alloys and Combinations . 79

Table XXIII. Filler Alloys Recommended for Copper Alloys and Combinations ........................... 81

Table XXIV. Filler Alloys Recommended for Titanium Alloys and Combinations ........................ 81

Table XXV. Acceptable Preweld and Postweld Cleaning Methods ................................................. 82

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 7 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

LIST OF FIGURES

Figure Page

Figure 1. Welding Techniques .......................................................................................................... 29

Figure 2. Mismatch and Peaking ...................................................................................................... 31

Figure 3. Fillet Weld Throats ............................................................................................................ 32

Figure 4. Fillet Welds ....................................................................................................................... 33

Figure 5. Aluminum Fusion Butt Weld ............................................................................................ 46

Figure 6. EBW Butt Weld ................................................................................................................. 47

Figure 7. EBW Max Weld Crown and Root Widths for Penetration Depths (D) ≤ 1.6 in [41 mm] 48

Figure 8. Min EBW Root Width for Penetration Depths (D) ≤ 0.2 in [5 mm] ................................. 49

Figure 9. Min EBW Root Width for Penetration Depths (D) of 0.2-1.6 in [5-41 mm] .................... 50

Figure 10. C-FSW Zone .................................................................................................................... 51

Figure 11. SR-FSW Zone ................................................................................................................. 51

Figure 12. Titanium Full-Penetration Joint Welds ........................................................................... 53

Figure 13. Titanium Butt Joint Maximum Allowable Weld Width (W) versus Thickness (t) ......... 54

Figure 14. Titanium Fillet Joint Maximum Allowable Weld Width versus Thickness .................... 55

Figure 15. Titanium Maximum Fillet Weld Size L

MIN

= thickness of the thinnest member ............ 56

Figure 16. Titanium Fillet Weld Dimensions for Acute Angle and Drop Through ......................... 56

Figure 17. Weld Size Requirements for Butt Welds......................................................................... 57

Figure 18. Class A Butt Weld Fusion Zone Weld Size Limits ......................................................... 58

Figure 19. Class B Butt Weld Fusion Zone Weld Size Limits ......................................................... 59

Figure 20. Class C Butt Weld Fusion Zone Weld Size Limits ......................................................... 60

Figure 21. Weld Size Requirements for T and Corner Welds .......................................................... 61

Figure 22. Class A, T and Corner Weld Fusion Zone Weld Size Limits ......................................... 62

Figure 23. Class B, T and Corner Weld Fusion Zone Weld Size Limits .......................................... 63

Figure 24. Class C, T and Corner Weld Fusion Zone Weld Size Limits .......................................... 64

Figure 25. External Discontinuities for Aluminum Alloys ............................................................... 69

Figure 26. Internal Defects for Aluminum Alloys ............................................................................ 70

Figure 27. EBW Porosity Acceptance Criteria for Steels, Heat Resistant ........................................ 72

Figure 28. Conventional-Friction Stir Welding Process ................................................................... 90

Figure 29. Self Reacting-Friction Stir Welding Process ................................................................... 90

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 8 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

SCOPE

This process specification establishes uniform requirements for the design, fabrication, and

inspection of welds in flight hardware. This process specification may also be used for special test

articles and ground support equipment. This specification combines the lessons learned from

extensive Agency-wide welding engineering experiences and combines the requirements of project,

Center, other government, and industry documents used for the manufacture of historic spaceflight

hardware such as Saturn, the Space Shuttle, and the International Space Station.

When this process specification is specified on contract documents, the contractor may submit an

alternative, corporate, detailed weld process specification that meets the intent of this specification.

Industry, government, and company specifications may be used for welding hardware in lieu of this

specification if approved by the responsible National Aeronautics and Space Administration

(NASA) Technical Authority. The content of this process specification meets the intent of NASA-

STD-5006A.

Purpose

The purpose of this process specification is to establish the minimum process control requirements

for the design, fabrication (including the qualification of welders, welding operators, and welding

procedure specifications), and quality assurance of manual, semi-automatic, mechanized, and

automatic welds in flight hardware, special test articles and ground support equipment used by or

for Marshall Space Flight Center (MSFC). This process specification will be used for flight

hardware. This process specification may be used on special test articles and ground support

equipment.

Applicability

This process specification is approved for use by MSFC and may be cited in contract, program, and

other documents as a technical requirement. This process specification may also apply to

contractors and subcontractors to the extent specified or referenced in their contracts.

This standard applies the following convention: all mandatory actions (i.e., requirements) are

denoted by statements containing the term “shall”, the term “will” denotes an expected outcome,

and the terms “may” or “should” denote explanatory or guidance text indicated in italics beginning

in Section 4.0.

Applicable Processes

This process specification is applicable to fusion arc, solid-state, resistance and high-energy

density weld processes for joining metallic materials. These include, but are not limited to, the

following and the pulsed derivate:

(1) FCAW - Flux-Cored Arc Welding

(2) GMAW - Gas Metal Arc Welding

(3) GTAW - Gas Tungsten Arc Welding

(4) PAW - Plasma Arc Welding

(5) SMAW - Shielded Metal Arc Welding

(6) SAW - Submerged Arc Welding

(7) VPPA - Variable Polarity Plasma Arc

(8) Direct Drive Friction Welding

(9) Inertia Friction Welding

(10) FRW - Friction Welding

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 9 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

(11) FSW - Friction Stir Welding

(12) FPW - Friction Plug Welding

(13) EBW - Electron Beam Welding

(14) LBW - Laser Beam Welding

Applicable Materials

This process specification covers all metallic materials used in the manufacture of flight hardware.

Units of Measurement

This standard makes use of both U.S. Customary Units (US) and the International System of Units (SI).

The latter are shown within brackets ([ ]) or in appropriate columns in tables and figures. The

measurements may not be exact equivalents, therefore, each system must be used independently.

Tailoring

Tailoring of this process specification shall be formally documented as part of the program or project

requirements and approved by the responsible NASA Technical Authority. These requirements may be

tailored by constructing a matrix of applicable paragraphs and non-applicable paragraphs. Tailoring may

include using existing or previously developed contractor processes and standards as a submittal of the

various required plans. Otherwise, the tailoring of requirements may be documented in the Materials and

Processes Selection, Control, and Implementation Plan by providing the degree of conformance and the

method of implementation for each requirement identified herein.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 10 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

APPLICABLE DOCUMENTS

Applicable Standards and Documents

The latest issues of the following documents form a part of this specification to the extent specified

herein. In the event of a conflict between the documents referenced herein and the contents of this

specification, the content of this specification will take precedence. The contractor may pursue

substituting equivalent specifications and documents to the ones identified herein as long as the

substitution does not compromise the intent of the specifications and documents identified herein and is

approved by NASA/MSFC before implementation.

Military

MIL-HDBK-1823 Nondestructive Evaluation System Reliability Assessment

MIL-A-18455 Argon, Technical

MIL-PRF-27401 Propellant Pressurizing Agent, Nitrogen

MIL-PRF-27407 Propellant Pressurizing Agent, Helium

BB-C-101 Federal Specification Carbon Dioxide (CO

2

): Technical and USP

BB-H-886 Federal Specification Hydrogen

CGA G-4.3 Commodity Specification for Oxygen

CGA G-5.3 Commodity Specification for Hydrogen

CGA G-6.2 Commodity Specification for Carbon Dioxide

CGA G-9.1 Commodity Specification for Helium

CGA G-10.1 Commodity Specification for Nitrogen

CGA G-11.1 Commodity Specification for Argon

National Aeronautics and Space Administration (NASA)

NASA-STD-5006A General Fusion Requirements for Aerospace Materials Used in Flight

Hardware

NASA-STD-5009 Nondestructive Evaluation Requirements for Fracture-Critical Metallic

Component

NASA-STD-5019 Fracture Control Requirements for Spaceflight Hardware

NASA-STD- 6016 Standard Materials and Processes Requirements for Spacecraft

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 11 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

NASA-STD-8739.12 Metrology and Calibration

MPCV 7016 Cross Program Fluid Procurement and Use Control Specification

NPR 8715.1 NASA Occupational Safety and Health Program

NPR 1441.1 NASA Records Management Program Requirements

Other Publications

ASTM E8/E8M Standard Test Methods for Tension Testing of Metallic Materials

AWS A2.4 Standard Symbols for Welding, Brazing, and Nondestructive

Examination

AWS A3.0 Standard Welding Terms and Definitions

AWS A5-ALL Filler Metal Procurement Guidelines

AWS A5.01M/A5.01 Welding Consumables – Procurement of Filler Metals and Fluxes

AWS A5.12M/A5.12 Specification for Tungsten and Oxide Dispersed Tungsten Electrodes for

Arc Welding and Cutting

AWS B2.1/B2.1M Specification for Welding Procedure and Performance Qualification

AWS B4.0 Standard Methods for Mechanical Testing of Welds

AWS C6.1 Recommended Practices for Friction Welding

AWS C6.2 Specification for Friction Welding of Metals

AWS C7.4/C7.4 M Process Specification and Operator Qualification for Laser Beam

Welding

AWS D17.1 Specification for Fusion Welding for Aerospace Applications

AWS D17.2/D17.2 M Specification for Resistance Welding for Aerospace Applications

AWS D17.3 Specification for Friction Stir Welding of Aluminum Alloys for

Aerospace Applications

AWS G2.4/G2.4 M Guide for the Fusion Welding of Titanium and Titanium Alloys

AWS QC1 Standard for AWS Certification of Welding Inspectors

NAS 410 NAS Certification & Qualification of Nondestructive Test Personnel

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 12 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

NAS 1514 Radiographic Standard for Classification of Fusion Weld Discontinuities

SAE AMS 2680 Electron-Beam Welding for Fatigue Critical Applications

SAE AMS 2770 Heat Treatment of Aluminum Alloy Raw Material

SAE AMS-W-6858A Welding, Resistance: Spot and Seam

Reference Documents

The documents listed in Appendix H are provided as background information for users of this

specification, defining the source of the requirements in sections 4.0 through 11.0 of this specification.

The listing in this section does not levy any new or relieve any specific requirements that are imposed

by this specification or other contractual documents associated with procurement of this specification

end item.

Order of Precedence

When requirements in this specification conflict with those on the engineering drawing, the

requirements on the engineering drawing will take precedence. Conflicts between this specification

and other requirements documents will be resolved by the responsible NASA Technical Authority.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 13 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

REQUIREMENTS

Safety

Industrial Safety

Appropriate personal protective equipment shall be used in all hazardous processes.

All hazardous materials and processes that are required in compliance with provisions of this

process specification and that are located or performed at sites other than MSFC are subject to

applicable federal, State, and local safety codes, standards, and regulations.

All hazardous materials and processes that are required in compliance with provisions of this

process specification and that are located or performed at MSFC shall be subject to NPR 8715.1.

System Safety

System safety engineering (SSE) shall identify critical and catastrophic hazards and

mitigations to eliminate and/or control the hazards of the welding operations.

SSE shall participate within the various program working groups, panel reviews, and

procedures and drawing reviews of welding systems and processes.

SSE shall participate in welding process reviews and decisions to ensure that safety concerns

are addressed and appropriate safety requirements and design criteria are implemented in accordance

with applicable program Safety, Reliability, and Quality Plan.

Specific Process Weld Requirements

Resistance Welding

Resistance welding shall be in accordance with AWS D17.2/D17.2M, or SAE AMS-W-6858A.

Laser Beam Welding

LBW shall be in accordance with AWS C7.4/C7.4M.

Friction and Inertia Welding

Direct drive friction or inertia welding shall be in accordance with AWS C6.2.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 14 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

JOINT CLASSES

Inspection Criteria

Welds performed using this process specification shall be classified in accordance with the

consequences of joint failure as described in the following sections.

Welds shall be inspected per Table I.

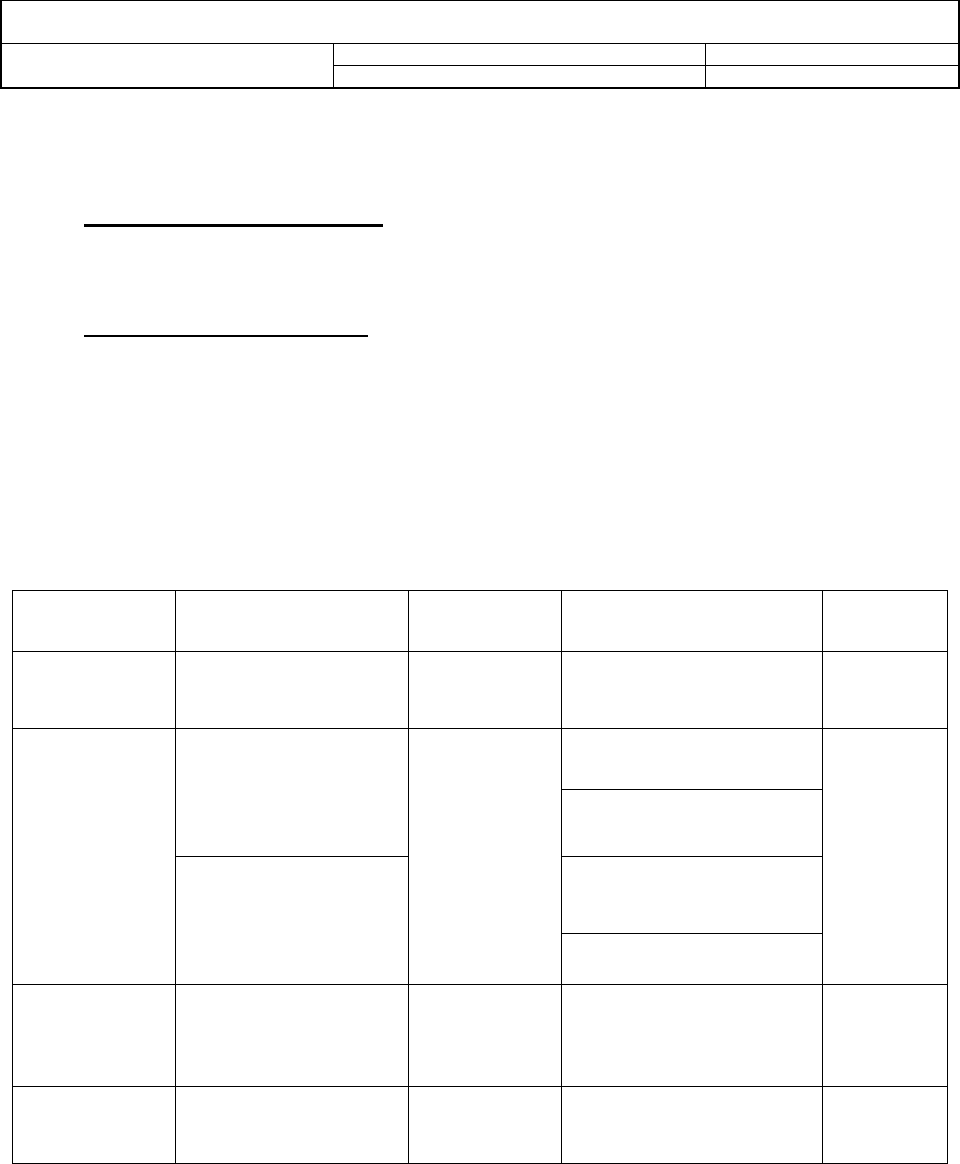

Table I. Minimum Inspection Requirements

Method of Inspection

Weld Class

A

B

C

Visual

X

X

X

Dimensional

X

X

X

Surface

X

X

–

Volumetric

X

X

1

–

Additional Inspection When Required by Drawing

X

X

X

1

Class B welds shall be subjected to volumetric inspection if required by engineering design and

specified by drawing or special instruction.

Joint Classifications

Class A Joints

A weld joint whose failure would result in loss of crew, loss of vehicle, or loss of mission

shall be classified as a Class A joint.

Class A welds shall pass quantitative surface and volumetric NDE and visual inspection in

accordance with Table I and Section 11.0.

Class A fillet welds shall require a Materials Usage Agreement (MUA) in accordance with

NASA-STD-6016.

Based on consequences of failure, all fracture-critical welds are, by definition, Class A joints. If the quality of

the Class A joint cannot be verified as required by this specification, e.g., inaccessible volume or root surfaces,

then alternative rationale for acceptance is to be presented to the responsible NASA Fracture Control Board for

approval as required by NASA-STD-5019.

Class B Joints

A fail-safe weld joint shall be classified as a Class B joint.

Class B welds shall pass quantitative NDE and visual inspection in accordance with Table I

and Section 11.0.

Class C Joints

A nonstructural weld joint shall be classified as a Class C joint.

Class C welds shall pass a visual inspection in accordance with Table I and Section 11.0.

Class C welds shall be fully contained so failure in service would have minor or no effect on

the efficiency of a system and so endangerment to personnel would not occur.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 15 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

EQUIPMENT

Welding Equipment

All welding equipment shall be capable of producing welds that meet the quality requirements

specified herein.

Welding equipment shall be procured in accordance with an approved specification.

Equipment parametric fluctuations, variations that occur in equipment without human

intervention, shall be characterized by the equipment vendor and may not be cause for rejection.

Violations of tolerances related to equipment variations during the steady-state portion of the

weld that occur for less than 6 seconds shall not be cause for rejection.

Variations caused by the sampling rate per second can cause the readings to be outside the certified range. As

long as the number is random (hence, the 6-sec limit), it is not cause for rejection.

Weld parameters controlling the heat input for automatic and mechanized welds shall be

recorded continuously using automatic recording devices during the weld operation.

Process parameter data shall be logged at a rate that sufficiently captures all essential variable

data and minimizes the risk of signal artifacts.

The minimum recommended data capture rate for FSW is 5 Hz.

Process parameter log files shall be stored electronically in compliance with contractual

requirements

Equipment fluctuations or natural variations that occur in equipment without human

intervention and change the readings of the qualified nominal parameter settings shall not be cause for

rejection.

EBW equipment shall be a high vacuum type for welding in 5x10

-4

torr [6.7x10

-2

Pa] (or better)

vacuum.

Acceptance Testing

New or relocated welding machines shall be acceptance tested under the cognizance of the

responsible organization before release to manufacturing departments for production welding.

Equipment shall meet the requirements of the applicable purchase specification or design

specification.

All equipment (electrical and mechanical) shall operate reliably within the range of

parameters and duty cycle to be used for welding of production parts.

Calibration

Calibration shall be in accordance with NASA-STD-8739.12. For MSFC operations,

reference MPR 8730.5 in Appendix H.

Welding shall be accomplished using equipment containing calibrated data indicators within

manufacturer-specified tolerance ranges that display and/or record welding parameters.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 16 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Measuring instruments, meters, gauges, or direct reading electrical control circuits to be used

for welding operations shall be calibrated.

Calibration shall be verified periodically at intervals specified by the manufacturer of the

welding equipment, not to exceed 1 year, or when any maintenance or repair is performed that may

have changed calibration.

Current calibration status shall be posted or made available at the equipment and verified prior

to use.

Calibration record(s) shall be maintained by the responsible cognizant organization and made

available upon request.

The office of record for MSFC calibration records is the MSFC Metrology and Calibration Laboratory.

Maintenance and Maintenance Records

A preventive maintenance plan shall be implemented for welding equipment.

Welding machines shall have adequate periodic preventive maintenance service.

A current record of each maintenance repair shall be maintained for each welding machine.

Maintenance records shall be maintained by the responsible cognizant organization and made

available upon request.

Records shall include unique identification of equipment, date, and time of service/repair,

description of work completed, and traceability to employee performing the maintenance.

Weld Equipment Modification

Weld equipment validation shall be required when the welding equipment has failed to

accomplish the intended function or when any major modification is made to the equipment.

Major modifications may include any changes to relevant sensor equipment, support hardware,

software, or the weld system affecting process control.

When any major modification is made to the equipment a validation plan shall be submitted to

the responsible NASA Technical Authority for approval.

Equipment validation documentation shall be retained as temporary records per section 11.3.7

and made available upon request.

Tooling and Fixtures

General Requirements

Tooling and fixtures shall be identified in the Weld Procedure Specification (WPS).

Tooling and fixtures used in the welding operation shall be constructed of materials that do

not adversely affect the weld process and are not detrimental to the weld quality.

Tooling and fixtures shall not be a source of contamination of the weld or of the part being

welded.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 17 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Fixtures within 2 in. [5 cm] of the weld joint shall be visually free from rust, oxide scale, dirt,

oil, grease, paint, low melting alloys, e.g., lead, tin, cadmium, and other contaminants detrimental to

weld quality.

Paint may be within 1 in. [2.5 cm] on FSW fixtures.

Clamping and Alignment

Tooling and fixtures shall maintain component alignment during welding and ensure

compliance with dimensional requirements of section 10.3 of this process specification.

In FPW, there shall be contact between the component and the backing anvil.

Magnetic Materials

When used with arc or EBW, magnetic materials shall be degaussed before welding.

Degaussing of magnetic materials shall be controlled by the WPS when necessary for the

successful completion of the weld.

Degaussing – Prior to welding, ferromagnetic parts or tooling which have been subjected to

the influence of magnetic fields (e.g., GTAW tack welded, machined using magnetic chucks, or

magnetic particle inspected) shall be degaussed prior to welding.

Degaussing is to prevent arc and electron beam deflection while welding the joint.

Chill Bars

Chill bars shall not be used in such a manner that the weld joint location surfaces pick up chill

bar material.

Chrome-plated copper chill bars may be used because copper or copper alloys have resulted in liquid metal

embrittlement of austenitic stainless steels and some cobalt alloys.

Electroless nickel plating introduces phosphorus, which is detrimental to the weld process.

Aluminum, aluminum alloys, or other low melting alloys shall not be used for chill bars for

non-aluminum alloy weld joints.

Electron Beam Welding

EBW shall be performed in a vacuum with absolute pressure of 0.001 torr [0.133 Pa] or lower.

Back-up material used to deflect or absorb residual EBW energy shall be of the same alloy as

the part being welded, except when authorized by the NASA Technical Authority.

Alternate back-up materials may be used when specified by the WPS.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 18 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

MATERIALS

Base Metals

Unless otherwise specified or approved by the procuring agency, the base metal alloy shall

conform to applicable material specifications as defined on the engineering drawing.

The base metal type and condition, as well as the appropriate material specification shall be

recorded as a part of the WPS.

Weld start and run-off tabs, when used, shall be of the same alloy as the material being joined

and be welded with the same filler metal specified on the drawing or WPS.

Backing material may be used when authorized by the WPS.

Filler Metals

Weld filler materials shall be purchased according to AWS A5.01/A5.01M.

Unless otherwise specified or approved by the procuring agency, filler metal alloy shall

conform to all AWS A5 filler metal material specifications (AWS A5-ALL).

Weld filler materials and the appropriate specifications shall be recorded on the WPS.

Weld filler materials shall be stored under conditions to maintain filler material cleanliness and

quality.

Uncoated weld filler wires shall be identified with a unique identification placed at the lowest

level of control, i.e., wire, package, tube, to ensure material traceability of all uncoated welding filler

wires.

Recommended weld filler metals are listed in Appendix F.

Metal consumable inserts shall be certified, their material traceability maintained, and both

recorded as part of the WPS.

Material traceability for friction plugs shall be ensured.

Commercially pure titanium filler metal shall not be used for joining Ti-6Al-4V weld joints.

Shielding Gas

Welding-grade gases conforming to the applicable industry or military specifications shall be

used for gas shielding when required.

Argon gas shall conform to the requirements of MIL-A-18455 or CGA G-11.1.

Nitrogen gas shall conform to the requirements of MIL-PRF-27401 or CGA G10.1.

Oxygen gas shall conform to the requirements of CGA G-4.3.

Helium gas shall conform to the requirements of MIL-PRF-27407 or CGA G-9.1.

Hydrogen gas shall conform to the requirements of BB-H-886 or CGA G-5.3.

Carbon dioxide gas shall conform to the requirements of BB-C-101 or CGA G-6.2.

The shield gas type and flow rates shall be recorded as a part of the WPS.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 19 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Inert gas back-side shielding shall be used on joints requiring full or partial penetration on

alloys susceptible to heavy oxide formation on the root side, the formation of which cannot be removed

by wire brushing and will interfere with surface inspection.

Only helium or argon shielding gas shall be used for welding titanium and titanium alloys.

Tungsten Electrodes

Tungsten electrodes shall conform to AWS A5.12/A5.12M.

The electrode diameter, tip shape and alloy shall be recorded as a part of the WPS.

FSW Pin Tools

FSW pin tools (shoulders and pins) and tack tools shall be made of materials that resist wear

during welding.

Pin and shoulder service life shall be demonstrated to meet the intended use and the use of pins

and shoulders limited to the demonstrated life.

Pins and shoulders that have reached the specified service life shall be marked and removed

from service to preclude accidental future use in the FSW production process.

If used for more than one weld joint, pins and shoulders shall be cleaned and inspected as

required before reuse on production hardware.

Pin tools shall be visually inspected after each production weld for unacceptable wear and

damage. Cracks, pits, flakes, and missing or broken threads shall result in the rejection of the pin tool

from use in production.

Findings of pin tool visual inspections shall be recorded and hardware welded with damaged pin

tools dispositioned before acceptability for use.

Pin tool design and materials shall be recorded as part of the WPS.

Anvils and Plug Weld Backing Material

Unless otherwise specified or approved by the procuring agency, anvil materials shall conform

to applicable government and/or industry specifications for each given alloy group.

Anvil material shall be resistant to deformation under the loads and temperatures experienced

during C-FSW and FPPW.

Anvil material shall not chemically react with the components to be joined.

Anvil and plug weld backing materials shall be recorded as part of the WPS.

Friction Plugs

Unless otherwise specified or approved by the procuring agency, friction plug materials shall

conform to applicable government and/or industry specifications for each given alloy group and their

material traceability be ensured.

Plugs shall be stored in an area that precludes their degradation by humidity, contamination, or

chemical attack.

Plug weld design and material shall be recorded as part of the WPS.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 20 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

WELDER PERFORMANCE AND WELD PROCEDURE QUALIFICATION

Welder Performance Qualification

Operators of welding equipment shall be certified by successful completion of a qualification

test for the applicable process.

Each fusion welder or fusion welding operator shall be qualified in accordance with AWS

D17.1, Section 5 and accepted to Class A requirements of this process specification.

7.1.1.1.1 All qualification groove welds shall be radiographically inspected.

7.1.1.1.2 All fillet welds with a base metal thickness more than 0.063 in [1.6 mm] shall be bend tested

or examined metallographically.

Other requirements may be added but not be substituted for the requirements in AWS D17.1 Section 5.

FSW operators shall be qualified in accordance with AWS D17.3, Section 7 and accepted to

Class A requirements of this process specification.

FPW operators shall be qualified in accordance with AWS D17.3, Section 7, using a square

groove test weld in sheet for making plug welds accepted to Class A requirements of this process

specification.

Welder qualification testing shall be repeated at intervals not exceeding 5 years or when there is

evidence to question the ability of the welder or welding operator to meet the requirements for

qualification.

To maintain qualification, welders and welding operators shall have performed the weld process

on the alloy groups for which they are certified within the previous 6 months.

Proficiency demonstration shall be required if a welder or welding operator has not performed

the weld process on the alloy groups for which they are certified within the previous 6 months.

Records of operator certification documentation shall be maintained by the contractor’s quality

assurance organization as temporary records per section 11.3.7 and be provided to the procuring agency

before welding flight hardware.

Weld Procedure Specification

A WPS shall be qualified for each thickness and material combination. The allowable qualified

thickness range is shown in Table II.

The WPS shall be qualified on the production equipment before welding of the first production

part.

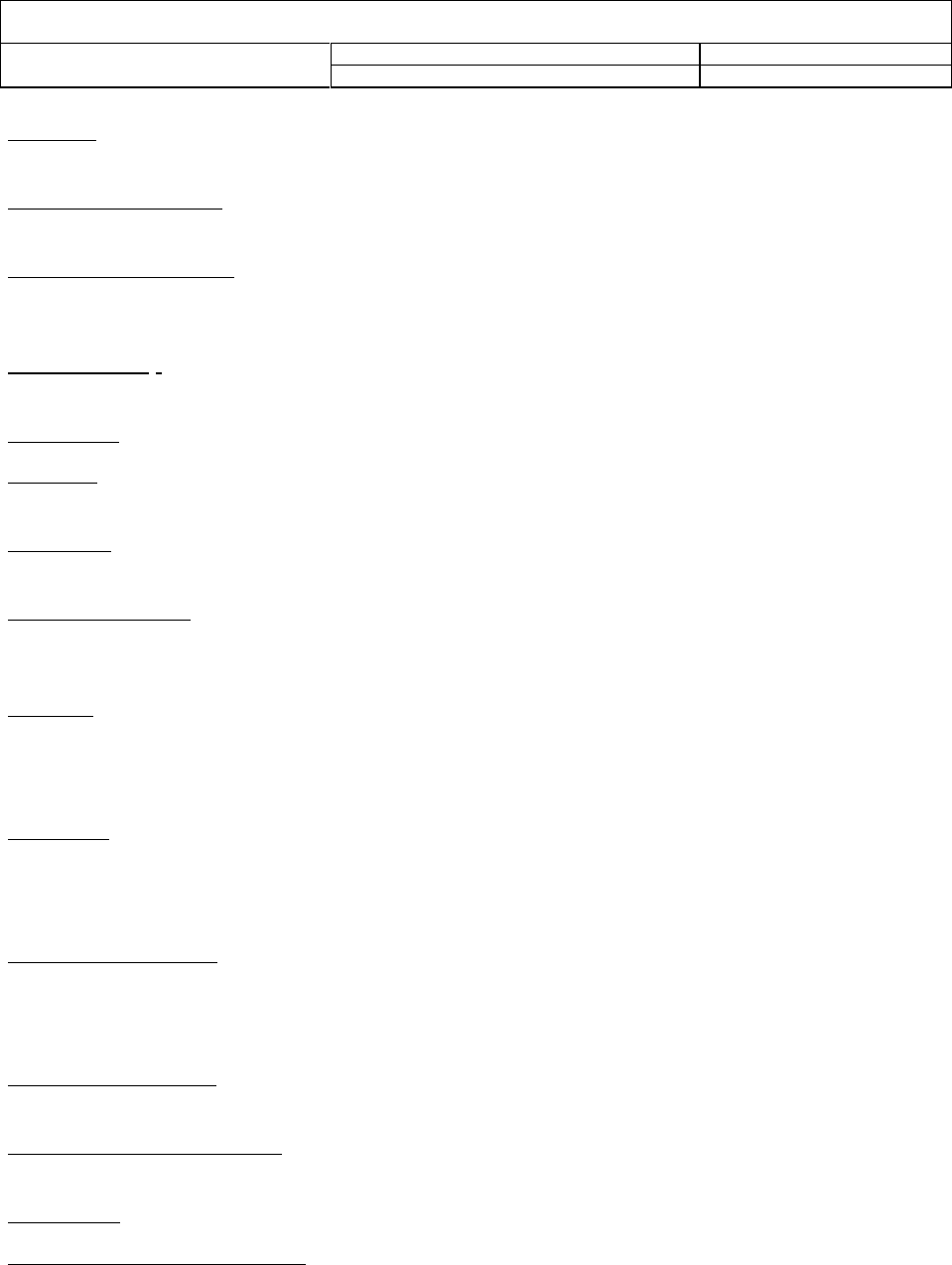

Table II. WPS Allowable Qualified Thickness Range

Process Application

Thickness (t) Range, in [mm]

Automatic

±0.020 [0.51]

Semi-Automatic

±0.020 [0.51]

Mechanized

±0.020 [0.51]

Manual

-0.5t / +2.0t

Orbital Tube

±0.1t

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 21 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Appendix E lists information that may be included in a WPS.

All test and evaluation data shall be recorded in the PQR.

The WPS shall contain all the information necessary to produce welds that consistently meet the

strength and quality requirements.

All essential variables shall be identified on the WPS.

For weld qualification tests, base metal and consumables shall be identified by lot or heat

number, type, and condition.

This base metal and consumable identification shall be maintained through all evaluation

processes.

The WPS shall document all other prewelding operations, setup conditions, welding

equipment, and any other pertinent information about the welding system used that affects the welding

operation.

Operator trim parameter tolerances used for automatic, semi-automatic, and mechanized

welding shall be listed in the qualified WPS.

Test samples representing the minimum and maximum heat input bounded in the WPS for

automatic, semi-automatic, and mechanized welds shall be tested in accordance with section 7.3 of this

process specification to verify acceptable welds

Procedure qualification welds shall be inspected using visual and NDE as specified in section

10.0 of this process specification, in accordance with Class A requirements.

Following visual and nondestructive inspection, the qualification welds shall be subjected to

the same processes as the production parts, including reinforcement removal, mechanical deformation,

stress relief, and thermal treatments associated with artificial aging or any operation affecting

mechanical properties.

Rejectable surface indications may be removed using mechanical means (sanding or

polishing), not rewelding. All visual and surface indications noted on the qualification welds that have

been mechanically removed shall be recorded in accordance with section 7.3.1 and the records retained

with the qualification weld documentation.

Operating ranges for current and voltage shall be established during the WPS qualification for

the steady-state portion of manual welds.

Tapered thickness welds shall be qualified at the maximum and minimum thickness (see

Table II) and with a full-length confidence weld (specified in section 7.3.4).

In recognition of the differences in welding conditions between a test panel fixture and a major

weld tool, the weld schedule developed on the test panel fixture shall be adjusted to the degree

necessary when welding on the major weld tool.

The variation shall be noted on the WPS.

The adjustment shall be allowed one time only on the first part welded on the major weld tool.

An adjustment approach that allows more than one adjustment shall be approved by the

responsible NASA Technical Authority.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 22 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

A confidence weld shall be completed before welding production hardware in accordance

with the requirements of 7.3.4.

Procedure Qualification Records

All test results, including visual, dimensional, and NDE, shall be recorded in the PQR.

The provisions of AWS B2.1/B2.1M, may be followed for fusion welds.

Weld Testing Methodology

Welds shall be tested in accordance with AWS B4.0. Alternative methods for weld performance

qualification verification shall be approved by the NASA Technical Authority.

For FSW, weld process zones should be evaluated using the qualified WPS at panel and confidence weld level.

Weld process zones may include intersections, weld overlap regions, restarts and closeout processes. This data

should be evaluated to the vehicle design requirements.

Tensile Tests

7.3.2.1.1 A minimum of five specimens shall be tested to qualify a groove weld procedure.

7.3.2.1.2 Plug weld tensile test specimens gauge width shall be a minimum of 1.3 times the major

diameter of the plug weld.

7.3.2.1.3 At a minimum, tensile specimens shall be tested to destruction at room temperature.

7.3.2.1.4 Percent elongation in 1.0 in. [2.5 cm] and/or 2.0 in. [5 cm] gauge lengths, 0.2% offset yield

stress, and ultimate tensile strength shall be recorded.

7.3.2.1.5 Percent elongation for round samples shall be measured across a length of 4 times the

diameter.

7.3.2.1.6 Weld strength shall meet or exceed the values in Appendix A.

7.3.2.1.7 Qualification welds for aluminum alloys used in cryogenic applications shall be tensile

tested at the intended use cryogenic temperature and at room temperature.

A minimum of four test specimens shall be tested to destruction.

Shear Tests

7.3.2.2.1 A minimum of five specimens shall be shear tested for fillet welds in corner, T, lap, or edge

joint configuration to qualify the weld procedure.

When it is not feasible to fabricate shear test specimens from qualification welds, shear tests may be

implemented in accordance with AWS B4.0.

7.3.2.2.2 The shear ultimate strength shall meet 60% of the weld ultimate tensile strength requirement

shown in Appendix A, unless otherwise approved by the responsible NASA Technical Authority.

Metallographic Examination

7.3.2.3.1 The welded joint shall be sectioned transverse to the direction of welding and the surface

adequately prepared for visual examination in an unetched condition at a magnification of 10X for weld

characteristics and defects.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 23 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

7.3.2.3.2 The section shall be lightly etched to reveal microstructure and reexamined at a higher

magnification (a minimum of 50X and not greater than 200X) for dimensional requirements and the

following weld quality requirements:

Overall fusion or consolidation of the weld, root penetration, burn-through, and blowholes.

Convexity, concavity, and size of bead, nugget or fillet.

Undercutting, underthickness, and overlapping.

Inclusions or voids.

Cracks.

Titanium Chemistry

7.3.2.4.1 Titanium weld qualification samples shall be analyzed for hydrogen, oxygen, and nitrogen

content, in accordance with the requirements of the base metal specification, to assure conformance to

the purity requirements.

7.3.2.4.2 The level of interstitial gases in the completed weld shall not exceed the worst-case

maximum level permissible in the procurement specification for the base materials being welded.

7.3.2.4.3 The weld cross section in titanium welds shall contain no titanium hydrides (TiH

2

) or alpha

case.

These two detrimental phenomena are indications of the hydrogen content exceeding the solubility limit and an

oxygen-enriched alpha-stabilized surface resulting from air contamination at elevated temperatures,

respectively.

Specimens described in section 7.3.2 of this process specification shall be produced and tested

at a minimum interval of 5 years for Class A and Class B welds to verify PQR data.

Failed qualification welds that have anomalies with a clear definable cause may be repeated with a 2-for-1

replacement.

Additional testing (fatigue, simulated service, hardness, impact, etc.) may be performed in support of meeting the

design requirements.

Confidence Weld Requirements

A confidence weld for each of the following different weld configurations shall be made and

tested in accordance with section 7.3.2 of this process specification to validate the WPS. Class C welds

are not required to have a confidence weld performed for qualification.

7.3.4.1.1 Tapered thickness welds made with automatic, semi-automatic, or mechanized weld

processes.

7.3.4.1.2 Pressure vessel or pressurized structure welds; excluding pressurized component welds.

7.3.4.1.3 All SR-FSW.

7.3.4.1.4 All C-FSW.

7.3.4.1.5 Cases in which the procedure qualification weld does not provide an appropriate

representation of the product form, e.g., forging, casting, extrusion, or geometry of the components

being welded, e.g., tubing, rolled shape.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 24 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

7.3.4.1.6 Class A weld without root side access to verify full penetration.

7.3.4.1.7 Primary structural vehicle or payload welds. This may include payload attachment

hardware or similar structures that constitute the primary load path within or between the vehicle and

payload.

The confidence weld shall replicate the production part with respect to section thickness,

alloy, heat treat condition, joint preparation, preweld cleaning, and fit-up and be made in the actual

production weld fixture, using the actual production welding equipment.

The confidence weld shall replicate the production weld with respect to length, startup, and

tailout or closeout.

7.3.4.3.1 A minimum of 15 total specimens shall be tested from the confidence weld(s).

Five specimens shall be taken from the beginning, five specimens from the middle, and five

specimens from the end of the confidence weld. Specimen removal locations shall be approved

by the NASA Technical Authority.

a) Beginning – As near the weld start as part geometry allows but outside of any overlap

region

b) Middle – As near the weld midpoint as part geometry allows

c) End – As near the weld end as part geometry allows but prior to any overlap region

In FSW, the closeout process shall be tested at the service temperature.

For weldments of insufficient size or configuration, the NASA Technical Authority shall

approve the test approach.

The pathfinder article may be used for the confidence weld if the above criteria are met.

Qualification shall be required if any of the essential variables on the WPS are modified.

Records

Records of test specimens that meet the acceptance requirements of this process specification

shall be signed and dated by a Safety Mission Assurance (SMA) representative as an accurate record of

the welding and testing of the procedure test weldment.

The WPS and PQR shall be prepared and retained as temporary records in accordance with

section 11.3.7, with the current WPS being accessible at the welding station to the welder or welding

operator.

All WPSs and PQRs shall be maintained and made available for review by the responsible

NASA Technical Authority before production.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 25 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

PREWELD OPERATIONS

Weld Joint Design

Joint configurations shall be documented in the WPS and on the design drawing.

Acceptable joint designs are butt, lap, corner, T, and edge. Corner and T joint designs should be designed to

minimize susceptibility to lamellar tearing.

Class A and Class B full-penetration weld joint configurations that will be inaccessible for root

side inspection are subject to the requirements of section 7.3.4 and shall be identified on engineering

drawings and require approval for use as a weld joint design by the responsible NASA Technical

Authority.

For Class A welds, faying surfaces of joints shall have a surface roughness of 32 to 125 µin

[0.81 to 3.2 µm] per ASME B46.1.

LBW and EBW weld joint edges shall be machined parallel to ensure proper fit-up and meet the

preweld joint fit-up requirements in Appendix B.

FSW joint design shall be butt joint configuration only.

Plug weld joint preparation shall be performed per the WPS or Engineering Drawing. This may

include deburring.

Preweld Cleaning

Preweld cleaning of contaminants detrimental to weld quality or filler materials and surfaces to

be welded shall be in accordance with Appendix G.

Preweld cleaning shall be accomplished in a controlled environment that does not degrade weld

quality and that is maintained until the weld operation is complete.

After surface preparation, parts shall be covered or otherwise protected to prevent

contamination until welding is completed.

Personnel performing the cleaning operation or any subsequent operation shall wear powder-

free, non-vinyl, moisture barrier gloves.

Before use, tooling (including hold-down clamps, anvils, and parts of welding fixtures that

contact or are placed in close proximity to the weld joint) shall be free of oil, moisture, and foreign

materials.

Tools and instruments used for measurements or other devices that contact the surfaces to be

welded shall be free of oil, grease, moisture, or other foreign materials before use.

Tools shall be cleaned initially and intermittently as necessary.

Preweld and interpass cleaning requirements shall be included in the WPS.

Stainless steel wire brushes shall be used in all instances where wire brushing is performed.

Low-current (10 ampere maximum), reverse–polarity, high-frequency arc cleaning (using manual, automatic,

semi-automatic, or mechanized welding equipment) may be used to remove oxides from iron-, nickel-, and

cobalt-base alloys.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 26 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Fusion welding shall be started within 24 hrs. of initiating preweld cleaning, unless otherwise

permitted by the responsible NASA Technical Authority.

Time between initiation of preweld cleaning and welding shall be documented in production

build records.

In aluminum alloys, C-FSW joints will subsequently be intersected by fusion welds shall be

cleaned by draw filing or scraping the abutting edges and scraping or wire brushing the crown and root

surfaces of the weld land 0.5 in [12.7 mm] beyond the shoulder diameter.

All SR-FSW joints in aluminum alloys shall be cleaned by draw filing or scraping the abutting

edges and mechanically abrading the crown and root surfaces of the weld land 0.5 in [12.7 mm] beyond

the shoulder diameter.

Following the mechanical cleaning operations described in sections 8.2.11 and 8.2.12 above, solvent cleaning by

wiping with lint-free clean cloth may be permitted.

The FSW full-penetration pass shall be started within 48 hrs. of initiating preweld joint cleaning

unless otherwise permitted by the responsible NASA Technical Authority.

Tack welding is not considered a full-penetration weld.

EBW shall start within 40 hrs. after surface preparation has been completed, unless otherwise

permitted by the responsible NASA Technical Authority, with the following exceptions:

EBW of aluminum alloys shall be performed within 8 hrs. after being cleaning.

If parts have been vacuum dried and stored in a sealed plastic film (other than polyethylene or

nylon) bag purged with dry argon or gaseous nitrogen, the parts shall be welded together within 100

hrs. of cleaning.

Weld joints adjacent to brazed surfaces shall be cleaned in accordance with Appendix G to

remove contamination from brazing operations.

All brazing alloy deposits shall be removed from the weld joint region that includes the joint

and the area within 0.25 in [6.4 mm] of the joint, unless otherwise specified on the engineering

drawing.

When welding precision-cleaned hardware, all welding of assemblies for precision-cleaned

systems (including tube preparation) shall meet the requirements of MPCV 7016.

Plugs used for friction plug welding and the material to be plug welded shall be cleaned by

abrasion to remove the oxide layer, followed by solvent cleaning within 8 hrs. of plug welding.

Preweld Joint Fit-up

After the parts have been mated, positioned and tacked for the welding operation, the joint shall

be verified for compliance with the preweld and postweld dimensional requirements of Appendix B of

this process specification.

Preweld joint gap requirements for specific materials and processes shall meet the requirements

listed in Appendix B.

The interrelationship of mismatch, joint gap, peaking, and pin tool offset shall be shown by

engineering analysis or test to assure that positive margins of safety exist for FSW.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 27 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Weld Start and Run-Off Tabs

Weld start and run-off tabs (when used) shall be of the same alloy as the detail parts being

welded.

Weld start and run-off tabs shall be cleaned in the same manner as the parts.

Tabs shall be integral with the part, being either machined in, welded with the same filler metal,

or rigidly attached to the part pieces before assembly.

Length of weld start and run-off tabs shall be established, based on the confidence panel test

results.

Use of weld start and run-off tabs shall be included in the WPS.

Laser and Electron Beam-to-Joint Alignment

Flat and Circular Welds

Before welding every weld joint of every production run, the entire length of the joint shall be

leveled to within ±0.005 in [±0.127 mm] using a calibrated dial indicator.

The assumed centerline of the beam shall be aligned within 30 min of the gun angle defined in

the approved weld parameter, as determined using a calibrated inclinometer in conjunction with a

surface at a known reference angle to the joint faces.

Circumferential Welds

Before welding every weld joint of every production run, the axis of the assembly shall be

leveled, using a calibrated dial indicator to within ±0.005 in [±0.127 mm] in relation to reference

surfaces for weld joint faces perpendicular to the axis.

For off-axis joints, the assumed centerline of the beam shall be aligned within 30 min of the

gun angle defined in the approved weld parameter, using a calibrated inclinometer in conjunction with

a surface at a known reference angle to the joint faces.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 28 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

PRODUCTION WELDING

Equipment Operational Readiness Check

A welding equipment operational readiness check shall be made immediately before a production weld

to verify that the equipment is operating properly.

An equipment checklist may be used to ensure equipment performance. Items such as pintool part and serial

number(s) (FSW), torch setup (fusion), air pressure, water pressure, shield gas flow, and other factors affecting

equipment performance may be verified before weld initiation.

Temperature Control.

Preheat, interpass, and postheat temperatures shall be controlled so as not to degrade the

properties of the material being welded.

These parameters shall be recorded in the applicable WPS.

Tack Welding

Tack welding shall be allowed, provided they are fully consumed by the final weldment.

After the final weldment is completed, the tack areas shall be inspected to the requirements of

the finished weld.

Tack welding parameters shall be included in the WPS and used to generate PQR data.

Tack welding parameters are not essential variables.

Aluminum alloy joints to be FSW shall be tacked using FSW unless authorized by the

responsible NASA Technical Authority.

Other tacking methods may be used provided requirements 9.3.1, 9.3.2 and 9.3.3 are met.

A tack weld made with EBW or LBW shall be made with a substantially reduced power density

from the certified full-penetration pass, up to and including the full length of the weld.

A full-penetration tacking pass using certified parameters may be used.

If a full-penetration tacking pass using certified parameters is used, it shall not exceed

10 percent of the weld joint length for EBW.

If a full-penetration tacking pass using certified parameters is used, it shall terminate in the

weld start and run-off tabs when applicable.

Welding Techniques

Square groove welds shall be completely penetrated from one side (Figure 1A).

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 29 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Figure 1. Welding Techniques

Partial-penetration groove welds shall be used only for Class C joints, unless approved by the

responsible NASA Technical Authority.

Two-sided welding of butt joints (Figure 1B) shall only be allowed under the following

conditions:

The weld shall be performed in a prepared groove joint (Figure 1C and Figure 1D), where it

can be verified the initial pass consumed the entire abutting edge.

Partial-penetration welds from one side shall be machined into the penetration root to sound

metal before completing the next pass.

At a minimum, visual inspection shall be used to ensure penetration.

Welding Procedure

A specific WPS for each weld shall be required for all production welds in accordance with the

requirements of section 7.2.1.

Procedure Departure

Any departure from the qualified WPS during production welding shall require withholding of

the component for MRB disposition, except as noted in section 5.1.4.

MRB records shall be maintained as temporary records per section 11.3.7.

The cause for departure shall be determined and corrective action taken before further

production welding.

Cosmetic weld bead / passes shall only be allowed if included in a qualified WPS.

After welding, the EBW vacuum chamber shall not be vented until the component has cooled to

a temperature below its oxidizing temperature, as specified in the qualified WPS.

SR-FSW shall be welded with the pin tool offset toward the retreating side of the joint in

accordance with Appendix B.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 30 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

POSTWELD OPERATION

The Weldment

Each completed weldment (both face and root sides) and the adjacent base metal for a minimum 0.5 in

[12.5 mm] on either side of the weld shall be inspected to ensure compliance with the requirements of

sections 10.2, 10.3, and 10.6 as dictated by the class of the weld, unless approved by the responsible

NASA Technical Authority.

General Workmanship Requirements

Uniform appearance of weld deposits, buildup, and root reinforcement shall be verified by visual

confirmation.

The face and root sides shall be free of surface cracks, crater cracks, other defects open to the

surface, and oxide scale.

Visual inspection of the root surface of C-FSW may be omitted if etch and dye penetrant inspection are

performed.

The weld deposits shall be free of open voids or unfused overlapping folds.

For fusion welds the edge of the weld deposit shall blend smoothly into the base metal without

unfused overlaps or undercuts.

Titanium alloy welds and adjacent base metal shall meet the color requirements of AWS

G2.4/G2.4M.

With the exception of titanium alloys, discoloration caused by vapor deposition during EBW may be acceptable.

The surface of FSW shall be free of galling, tears, or blisters.

By-products of the welding process, such as weld-spatter, oxide scale, soot, flash, or other by-

products, shall be removed from the welded component.

Dimensional Requirements

Welded Butt Joints

Welded butt joints shall have 100% penetration.

Welded butt joints shall meet the geometrical requirements in Appendix C.

The root bead width in fusion welds shall not exceed the maximum weld width specified in

Appendix C.

The allowable postweld mismatch (Figure 2) shall not exceed the values specified in

Appendix B.

The allowable postweld peaking (Figure 2) of the welded joint and adjacent base metal shall

not exceed the values in Appendix B.

A standard template or other calibrated electronic measurement device having specified

reference points shall be used for determination of peaking and mismatch.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 31 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Figure 2. Mismatch and Peaking

The combined effect of mismatch and peaking on the efficiency of the weld joint is such that one can be

increased if the other is decreased. A limited amount of mismatch and peaking greater than the values

in Appendix B can be tolerated if it can be shown by engineering analysis or test that positive margins

of safety exist.

Weld Reinforcement Removal

Weld reinforcement, both face side and root side, shall remain, unless specified by the

engineering drawing.

The weld bead reinforcement may also be removed to eliminate defects occurring in the outer zones of

the reinforcement unless otherwise specified on the engineering drawing.

For fusion welds, reinforcement removal shall not thin the weld or base metal below drawing

dimensional requirements.

When flush contour is required by the welding symbol, weld reinforcement shall not exceed

0.015 in [0.4 mm].

Metal removal shall be such that the mechanically reworked area blends smoothly, e.g., 0.125

in [3.2 mm] radius, with adjacent material without abrupt sectional changes.

Surface roughness, after reinforcement removal, shall not exceed 250 µin [0.006 mm] or the

specification on the drawing.

Grinding of base metal shall not be done when wall thickness cannot be verified after

grinding.

MSFC Technical Standard

EM30

Title: Process Specification – Welding

Aerospace Hardware

Document No.: MSFC-SPEC-3679

Revision: A

Effective Date: October 22, 2018

Page 32 of 92

CHECK THE MASTER LIST – VERIFY THAT THIS IS CORRECT VERSION BEFORE USE

Flash material in solid-state welds shall be removed.

Techniques to remove flash, metal slivers, anvil marks on C-FSW and other sharp or raised

metal shall not interfere with postweld NDE inspections.

Material thickness shall not be reduced below the allowed underthickness specified in Appendix