ENVIRONMENTAL ASSESSMENT KORE

Power − KOREPlex Facility, City of

Buckeye, Maricopa County, Arizona

Environmental Assessment and Draft Finding of No

Significant Impact

DOE/EA-2222

June 2023

KOREPlex Facility Environmental Assessment

Contents

Page i

CONTENTS

1.0 Purpose and Need ......................................................................................................... 1

1.1 Purpose and Need for Agency Action .......................................................................... 1

1.2 Background .................................................................................................................. 1

1.3 Scope of Environmental Assessment ........................................................................... 2

2.0 Description of the Proposed Action ............................................................................. 4

2.1 Construction ................................................................................................................. 6

2.1.1 Facilities .................................................................................................................... 6

2.1.2 Stormwater Management ........................................................................................... 8

2.1.3 Utilities ....................................................................................................................... 8

2.1.4 Transportation ........................................................................................................... 9

2.1.5 Schedule ................................................................................................................. 10

2.2 Operations ................................................................................................................. 10

2.2.1 Personnel ................................................................................................................ 10

2.2.2 Traffic and Transportation ........................................................................................ 11

2.2.3 Production ............................................................................................................... 11

2.2.4 Waste Management ................................................................................................. 19

3.0 Environmental Consequences ................................................................................... 20

3.1 Aesthetics and Visual Resources ............................................................................... 20

3.2 Water Resources ....................................................................................................... 21

3.2.1 Surface Water .......................................................................................................... 21

3.2.2 Groundwater ............................................................................................................ 23

3.3 Air Quality .................................................................................................................. 23

3.3.1 Setting ..................................................................................................................... 23

3.3.2 Emissions Analysis .................................................................................................. 23

3.4 Biological Resources.................................................................................................. 27

3.4.1 Vegetation ............................................................................................................... 27

3.4.2 Wildlife ..................................................................................................................... 27

3.5 Cult

ural Resources .................................................................................................... 28

3.5.1 Historic Properties ................................................................................................... 28

3.5.2 Consultation with Native American Tribes ................................................................ 29

3.6 Socioeconomic Resources and Environmental Justice .............................................. 30

3.6.1 Socioeconomics ...................................................................................................... 30

3.6.2 Environmental Justice .............................................................................................. 31

3.7 Human Environment .................................................................................................. 32

3.7.1 Transportation ......................................................................................................... 32

3.7.2 Public and Occupational Safety and Health ............................................................. 33

3.7.3 Waste Management ................................................................................................. 34

3.8 Cumulative Impacts ................................................................................................... 36

3.8.1 Air Quality ................................................................................................................ 37

3.8.2 Greenhouse Gas Emissions .................................................................................... 37

3.8.3 Transportation ......................................................................................................... 38

4.0 Draft Finding ................................................................................................................ 39

KOREPlex Facility Environmental Assessment

Contents

Page ii

5.0 List of Preparers .......................................................................................................... 40

5.1 U.S. Department of Energy ........................................................................................ 40

5.2 Hilgartwilson, LLC ...................................................................................................... 40

5.3 KORE Power, Inc. ...................................................................................................... 40

6.0 References ................................................................................................................... 41

KOREPlex Facility Environmental Assessment

Contents

Page iii

LIST OF FIGURES

Figure 1 Regional Overview .............................................................................................. 3

Figure 2 Aerial Photograph ............................................................................................... 5

Figure 3 Proposed Action Site Layout ............................................................................... 7

Figure 4 Mixing ................................................................................................................12

Figure 5 Coating ..............................................................................................................13

Figure 6 Drying ................................................................................................................13

Figure 7 Roll Pressing ......................................................................................................14

Figure 8 Notching/ Slitting ................................................................................................14

Figure 9 Die Cutting .........................................................................................................15

Figure 10 Stacking .............................................................................................................15

Figure 11 Welding ..............................................................................................................16

Figure 12 Electrolyte Filling ................................................................................................16

Figure 13 Formation ..........................................................................................................17

Figure 14 Aging .................................................................................................................18

Figure 15 Degassing and Sealing ......................................................................................18

Figure 16 Grading ..............................................................................................................19

Figure 17 FEMA Flood Zones and National Wetlands Inventory ........................................22

Figure 18 Air Quality ..........................................................................................................24

LIST OF

TABLES

Table 1 Estimated Development Areas by Phase ............................................................ 4

Table 2 Estimated Facility-Wide Emissions ....................................................................26

Table 3 Population and Ethnicity (2020 Census) ............................................................31

Table 4 Selected Variables from EPA’s EJ Screening Tool .............................................32

Table 5 Annual Projected Operational Waste Generation and Management ..................35

Table 6 Estimated GHG Emissions .................................................................................37

LIST OF APPENDICES

Appendix A List of Permits

Appendix B Battery Basics

Appendix C Screening Analysis for Threatened and Endangered Species

Appendix D Consultation with Agencies and Native American Tribes

KOREPlex Facility Environmental Assessment

Contents

Page iv

ACRONYMS AND ABBREVIATIONS

Acronym

Definition

Act Section 136 of the Energy Independence and Security Act of 2007, as amended

ADEQ Arizona Department of Environmental Quality

ADOT Arizona Department of Transportation

AGFD Arizona Game and Fish Department

APE area of potential effect

APS Arizona Public Service Company

ATVM Program Advanced Technology Vehicle Manufacturing Loan Program

BACT best available control technology

CFR Code of Federal Regulations

City City of Buckeye

CO carbon monoxide

CO

2

carbon dioxide

DOE U.S. Department of Energy

EA environmental assessment

EJ environmental justice

EPA U.S. Environmental Protection Agency

FEMA Federal Emergency Management Agency

FTZ Foreign Trade Zone

GHG greenhouse gas

GWh gigawatt-hours

HAP Hazardous air pollutant

HVAC heating, ventilation, and air-conditioning

IPaC Information for Planning and Consultation

KORE Power KORE Power, Inc.

LFP lithium-iron-phosphate

LPO Loan Programs Office

MC Maricopa County

MCAQD Maricopa County Air Quality Division

NAAQS National Ambient Air Quality Standards

NATA

National Air Toxics Assessment

NEPA National Environmental Policy Act

NMC nickel-manganese-cobalt

NMP n-methyl-pyrrolidone

NO

X

nitrogen oxides

OSHA the Occupational Safety and Health Administration

PM Particulate-matter

PM

10

equal to or smaller than 10 microns in diameter

PM

2.5

less than 2.5 microns in diameter

RCRA Resource Conservation and Recovery Act

SHPO State Historic Preservation Office

SO

2

sulfur dioxide

KOREPlex Facility Environmental Assessment

Contents

Page v

Acronym

Definition

SR State Route

U.S.C. United States Code

USFWS U.S. Fish and Wildlife Service

VOC volatile organic compound

KOREPlex Facility Environmental Assessment

Purpose and Need

Page 1

1.0 PURPOSE AND NEED

1.1 Purpose and Need for Agency Action

The purpose and need for agency action are to comply with the U.S. Department of Energy

(DOE) mandate under Section 136 of the Energy Independence and Security Act of 2007, as

amended (Act) (42 United States Code [U.S.C.] Section 17013), to select projects for financial

assistance that are consistent with the goals of the Act.

KORE Power, Inc. (KORE Power), is a developer of large-scale battery cells, which are

produced primarily to support utility-scale energy storage systems and the e-mobility industry.

KORE Power has applied for a loan pursuant to DOE’s Advanced Technology Vehicle

Manufacturing Loan Program (ATVM Program), which was established to provide loans to

automobile and automobile parts manufacturers for the cost of re-equipping, expanding, or

establishing manufacturing facilities in the U.S. that produce advanced technology vehicles or

qualified components. The primary goal of the ATVM Program is to improve fuel economy for

light-duty vehicles and thereby reduce ozone precursors, greenhouse gas (GHG) emissions,

and particulate matter emissions associated with vehicle emissions.

Construction and operation of the proposed manufacturing facility would help to ensure a

reliable and independent U.S.-based supply of large-scale battery cells. Ultimately, the KORE

Power manufacturing facility would have an estimated annual production capacity of

approximately 12 gigawatt-hours (GWh) and be powered, in part, by an on-site solar

cogeneration plant. KORE Power has applied for financial assistance under the ATVM Program

to support development of the first phase of the proposed manufacturing facility. Phase 1 would

include construction and operation of an approximately 1.15-million-square-foot building that

would house two production lines, with an annual capacity of approximately 6 GWh. The project

would also involve administrative offices, material storage and mechanical systems buildings,

parking and access roads, and stormwater retention facilities.

The batteries produced by KORE Power support zero-emission EVs and will displace vehicles

with internal combustion engines and their associated emissions, such as ozone precursors,

particulate matter, and GHGs that contribute to global warming, as is consistent with the primary

goal of the ATVM Program. Financially supporting KORE Power's proposals would help bring

battery cells and batteries to market and into greater use, while contributing to the expansion of

zero-emission propulsion, thereby reducing overall national emissions of air pollutants and

human-caused GHGs.

1.2 Background

The ATVM Program is administered by DOE’s Loan Programs Office (LPO). LPO originates,

underwrites, and services loans for eligible projects, including those involving automotive or

component manufacturers. Pursuant to 10 Code of Federal Regulations (CFR) 611.2, eligible

projects include re-equipping, expanding, or establishing a manufacturing facility in the U.S. to

produce qualifying advanced technology vehicles or qualifying components; engineering

integration performed in the U.S. for qualifying advanced technology vehicles and qualifying

components; or manufacturing, recycling, processing, reprocessing, remediating, or reusing

materials, components, or subcomponents involving critical minerals, critical minerals

production, or the supply chain for such materials, as set forth in Executive Order 13953,

Executive Order Addressing the Threat to the Domestic Supply Chain from Reliance on Critical

Minerals from Foreign Adversaries, and Executive Order 13817, A Federal Strategy to Ensure

Secure and Reliable Supplies of Critical Minerals, as amended. The primary goal of the ATVM

Program is to improve fuel economy for light-duty vehicles and thereby reduce ozone

KOREPlex Facility Environmental Assessment

Purpose and Need

Page 2

precursors, greenhouse gas (GHG) emissions, and particulate emissions associated with

vehicle fuel combustion. The ATVM Program is designed to stimulate production of the

technology required to meet program objectives.

To fund its project, KORE power applied to the DOE ATVM Program for financial assistance.

LPO determined that the application substantially complete per the rules governing the ATVM

Program in 10 Code of Federal Regulations (CFR) Part 611. KORE Power was subsequently

invited to enter into the LPO’s due diligence process.

1.3 Scope of Environmental Assessment

LPO has prepared this EA to address the planned new construction and operation of Phase 1 of

the proposed manufacturing facility (the KOREPlex) on an approximately 214-acre parcel

(project area) in Buckeye, Maricopa County, Arizona (Figure 1). Future phases of the

KOREPlex facility are outside the scope of analysis for this EA and are not considered in this

evaluation.

Section 2.0 of this EA describes the construction and operation of the KOREPlex manufacturing

facility (the project) that is subject to LPO’s financial assistance, e.g. the proposed action.

Section 3.0 provides details regarding existing conditions occurring within and around the

project area and analyzes the potential environmental consequences (impacts) associated with

construction and operation of the KOREPlex manufacturing facility. Based on LPO’s review of

the scope of the project (i.e., construction and tooling of the new facility in Buckeye, Arizona),

the existing site conditions, and permit status, the scope of the issues analyzed in this EA

includes:

Aesthetics and visual resources

Water resources, including surface water and groundwater

Air quality, including GHG emissions and climate change

Biological resources, including vegetation, wildlife, and special-status species

Cultural resources

Socioeconomics and environmental justice and

Human environment, including transportation, public health and safety, and waste

management.

These resource areas were identified as potentially being affected by the project and each was

assessed to determine the nature, extent, and significance of those impacts (see Section 3,

Environmental Consequences). The assessment combined desktop research and analysis of

existing available information with select field studies, including site assessments related to

cultural resources, biological resources, and the identification of potential jurisdictional waters of

the U.S.

Because the site for the proposed KOREPlex facility is

in a rural area, on previously disturbed

land (former agricultural production) away from sensitive noise receptors, and within an area

zoned for industrial use, impacts on soil, geology, land use, recreational resources, as well as

noise sensitive receptors are not anticipated. Additionally, the U.S. Army Corps of Engineers

has concurred that waters of the U.S., including wetlands, do not occur in the project area

(USACE 2022). As such, all of the aforementioned resources areas are not included in the

scope of this EA.

KOREPlex Facility Environmental Assessment

Purpose and Need

Page 3

Figure 1 Regional Overview

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 4

2.0 DESCRIPTION OF THE PROPOSED ACTION

KORE Power is seeking to develop a manufacturing facility for the production of battery cells to

support energy storage systems and e-mobility industries. As depicted in Figure 2, KORE

Power proposes to construct the manufacturing facility on an approximately 214-acre parcel of

land located south of the Union Pacific Railroad between Baseline Road and the Buckeye Canal

and between State Route (SR) 85 to the west and Rooks Road to the east. The project area lies

within the north half of Section 1 of Township 1 South, Range 4 West, of the Gila and Salt River

Meridian.

The proposed KOREPlex facility will be located on private land approximately 1.5 miles west of

the Buckeye city center and historic downtown. The landscape setting in the vicinity of the

KOREPlex facility is predominantly rural, consisting primarily of agricultural land. However,

residential master-planned communities exist northeast and southeast of the project area.

Commercial and industrial uses exist or are under construction immediately west of SR 85,

south of the project area along Maricopa County (MC) 85 and to the north along Baseline Road.

The current land use designation is Employment, per the Imagine Buckeye 2040 General Plan,

Future Land Use Map (Matrix Design Group, 2018, as amended 2022). The current zoning

designation is General Commerce, per the Buckeye Zoning Districts Map (City of Buckeye,

2022). The project area is also within Buckeye’s Downtown Incentive District, which establishes

certain reduced fees to encourage redevelopment and growth in the City’s center.

During construction, the entire 214-acre site will be subject to mass grading and related

activities, including, but not limited to, grading for construction offices and laydown areas. The

entire project site has been previously disturbed by agricultural activities and includes fields,

access roads, and irrigation facilities.

Table 1. Estimated Development Areas by Phase

Primary Component

Estimated Development Area (acres)

Phase 1

Phase 2

Total

Buildings and tanks 26 24 50

Access roads and parking areas 30 20 50

Electrical substation 6 -- 6

Road, utility, and trail easements 25 -- 25

Drainage & retention 50 -- 50

Total

137

44

181

Landscape area* 12 10 22

*

The City of Buckeye requires 10 percent of the site to be subject to landscaping/site enhancement. This will overlap

and include portions of the area designated for drainage and retention; therefore, it is not included in the site totals.

The timing of for landscaping is subject to change.

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 5

Figure 2 Aerial Photograph

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 6

2.1 Construction

2.1.1 Facilities

The proposed DOE loan will support development of the first phase of the project, which will

include construction and operation of an approximately 1.15-million-square-foot manufacturing

facility that will house two production lines with an annual capacity of approximately 6 GWh. The

facility will also include administrative offices, material storage areas, buildings for mechanical

systems, an electrical substation, employee parking and access roads, and stormwater

retention facilities. Figure 3 Proposed Action Site Layout shows the preliminary site plan for

the project.

1

The manufacturing facility will comprise three primary sections, each of which will be

approximately 600 feet by 400 feet. Including the connected raw materials warehouse and

finished goods warehouse, the overall footprint of the main building will cover more than

900,000 square feet (roughly 2,250 feet long [east–west] by 400 feet wide [north–south]. The

manufacturing facility will have a single story, with varying ceiling clearances, depending on

equipment. The maximum building height will be approximately 75 feet. The building foundation

will be constructed with cast-in-place reinforced-concrete drilled piers/caissons. The roof system

will be fabricated with steel trusses supported by steel columns. The interior building floor will be

concrete, with epoxy coating (or similar) in some areas. Metal decking/equipment platforms will

be erected in some areas to accommodate some of the process units and/or heating,

ventilation, and air-conditioning (HVAC) systems. The manufacturing facility will include space

for battery production as the process progresses from the raw materials receiving area (with

truck bays) at the east end of the building to the finished goods area at the west end of the

building, at which point the batteries will be shipped by tractor-trailer rigs (see Section 2.2.3).

Accessory rooms and facilities will generally be constructed along the center spine of the

building (e.g., restrooms, employee break rooms, employee offices, conference rooms, quality

assurance laboratories, control rooms).

Other facilities will be staged in supporting structures south of the manufacturing facility; the

placement of these facilities, including tanks for chemical storage, will generally correspond to

the requirements of a particular process step. It is anticipated that four 30,000-gallon tanks and

one 5,000-gallon tank will be needed for electrolyte storage. Additional chemical storage will be

required for n-methyl-pyrrolidone (NMP) and carbon nanotubes. The chemical storage areas will

be constructed with cast-in-place reinforced-concrete for containment purposes; these areas will

slope to a sump pump in one corner to facilitate waste removal, if needed. Containment areas

will provide chemical-resistant water stops and have an epoxy coating to decrease absorption.

A pre-engineered metal building will be constructed to store defective and at-risk cells at the

west end of the area south of the manufacturing facility.

HVAC systems will include a combination of equipment, such as dehumidification units, rooftop

units, air rotation units, air handling units, and exhaust fans, for climate control and process

service. Preliminarily, the primary climate control system is anticipated to include an estimated

38 dehumidification units and 62 rooftop units.

1

The site layout depicted in Figure 3 is a preliminary site plan and subject to refinement and change.

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 7

Figure 3 Proposed Action Site Layout

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 8

The project will include an administration building at the west end of the manufacturing facility;

the administration building will be a two-story structure, consisting of approximately

30,000 square feet on each level. Visitor parking and an entrance will be provided farther to the

west. Facilities east of the manufacturing facility will include a chiller yard and compressed air

plant, a nitrogen plant, and an area for a substation that will be operated and maintained by the

Arizona Public Service Company (APS) (see Section 2.1.3). One guard house and gated entry

will be provided for Foreign Trade Zone (FTZ) ingress and egress along the north access road;

the guard house will comprise prefabricated modular assemblies.

2.1.2 Stormwater Management

The stormwater retention areas to be constructed will be capable of managing the volume of

runoff generated in the project area as a result of a 100-year, 2-hour return storm event.

Stormwater runoff from the northern portion of the site and building will be directed to an

approximately 10-acre retention basin at the northwest corner of the project area. Stormwater

runoff from the southern portion of the building and remainder of the project area will be directed

to an approximately 30-acre retention area along the southern edge of the project area.

Stormwater will be managed using a combination of overland flow and open channels to direct

runoff to surface inlets; runoff will flow into an underground storm collection system or directly to

retention areas. The basins will retain stormwater and discharge through evaporation and

drywells.

The project area will also have a regional stormwater conveyance channel along the eastern

edge of the property. It is not anticipated that on-site stormwater runoff will intermingle with off-

site stormwater conveyed in the regional channel. The size and configuration of the regional

channel have not been determined.

2

2.1.3 Utilities

Wet Utilities

Potable water will be provided by the City of Buckeye (City). This water will be used for drinking;

it will also be used in restrooms and a closed-loop chiller water. The City’s water will also feed

into a reverse-osmosis

and de-ionization treatment unit, providing ultrapure process water for

the facility.

A new water main will be constructed along the Rooks Road alignment. The new main will

connect to existing water lines in Baseline Road and MC 85. Water demand at the facility is

anticipated to total approximately 500 acre-feet per year, which is roughly half the amount of

water that had been used annually for irrigation associated with agricultural use.

3

KORE Power

plans to provide up to two locations for groundwater wells to the City in the project area.

4

Fire protection services will be provided by the City of Buckeye; water for fire-flow demand will

be provided from the City’s water distribution system. This will be supplemented by a fire-

2

If the channel is constructed as an underground culvert, the corresponding easement will be roughly 20 to 30 feet

wide. Alternately, if the channel is constructed as an earthen ditch, the width will be roughly 150 to 170 feet. Other

configurations, such as those involving drainage tiles or shotcrete, may be considered; these will alter the footprint of

the drainage easement.

3

The project area is under Irrigation Grandfather Right No. 58-103039.001, with an annual allotment of 985.73 acre-

feet of water (Arizona Department of Water Resources, 2023).

4

Groundwater wells will be constructed, operated, and maintained by the City of Buckeye; the wells are not a part of

the scope of this analysis. Groundwater from wells in the project area will be conveyed through water transmission

mains to an existing water campus; following potential treatment and chlorination, potable water will be conveyed

(indirectly) to the KORE Power facility through the City’s water distribution system.

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 9

protection pumphouse and storage tank that will be constructed on-site. The storage tank will be

sized in accordance with the requirements of the Fire Marshal, providing an available fire flow of

4,000 gallons per minute for 4 hours, or 960,000 gallons, and booster pumping capacity.

Domestic wastewater will be conveyed generally to the southeast corner of the site and

discharged from a connection to the City’s existing wastewater collection system in Rooks

Road. A small on-site lift station may be required to facilitate this connection. Currently, process

wastewater is anticipated to be collected from sumps located throughout the plant and pumped

to a wastewater treatment area south of the Phase 1 manufacturing facility. The primary

sources of process wastewater are anticipated to be water from cleaning the mixing areas and,

infrequently, tray washing.

The volume of process wastewater is estimated to be approximately 20,000 gallons per month.

Process wastewater is anticipated to be pretreated on-site and then discharged to the City’s

existing wastewater collection system. Routine sampling and monitoring will ensure compliance

with local limits established by the City of Buckeye’s industrial pretreatment program (City of

Buckeye, 2021). Alternately, process wastewater will be collected, stored in holding tanks with

secondary containment, and hauled by tanker truck to an off-site facility for treatment.

Dry Utilities

APS will be the electric utility provider. An electrical substation will be constructed on

approximately 6 to 8 acres of the site to facilitate three-phase, 69-kilovolt service to the site.

Natural gas service will be provided by Southwest Gas; it is assumed that the connection will

enter the site from the northeast and run east along the northern utility right of way.

It is anticipated that communication facilities will include fiber optic/internet. Robust internal

control systems will be designed and integrated into the facility.

2.1.4 Transportation

Access for construction on the site will be via northbound SR 85; a second point of

ingress/egress will be provided via Rooks Road northbound to Baseline Road at the northeast

corner of the site.

In anticipation of operations, KORE Power is working with the City of Buckeye and the Arizona

Department of Transportation (ADOT) to develop appropriate access routes and traffic solutions

for facility operations. As part of the project, the following improvements to transportation

infrastructure are anticipated, based on the latest draft of the traffic impact analysis (Southwest

Traffic Engineering, 2023).

Improvements to SR 85 will consist of the addition of a right-turn acceleration/ deceleration

lane along the frontage of the KOREPlex facility, in accordance with ADOT guidelines. This

driveway will be the primary route for employee and visitor ingress and egress to the site

(“west access”).

The primary truck access route to the facility will be via MC 85 and Rooks Road.

− For Phase 1, truck access to the KOREPlex facility will be via Rooks Road near the

northeast corner of the site (“north access”).

− Ultimately, a second point of connection to the KOREPlex facility will be added to Rooks

Road (“south access”).

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 10

− The southbound and northbound turn lanes to Rooks Road from the north and south

access roads on the KOREPlex facility will provide adequate storage to facilitate traffic

movements.

KORE Power will dedicate 70 feet along the eastern frontage of the project area, providing a

right of way for half-street improvements along Rooks Road plus an 8-foot-wide public utility

easement. The half-street improvements are anticipated to include three travel lanes, along

with a curb, gutter, and sidewalk.

The City of Buckeye will extend improvements to the Rooks Road alignment south of the

KOREPlex facility; this will include adding a bridge over the Buckeye Canal.

Stop signs will regulate traffic from Rooks Road to MC 85 and from Rooks Road to Baseline

Road. These intersections will be monitored as the KOREPlex facility and other developments

progress. Traffic signals will be installed when warranted.

It is anticipated that dual right-turn lanes will be constructed at the intersection of Southern

Avenue and northbound SR 85, either as part of the second phase of the KOREPlex facility

or if warranted by other development in the area.

2.1.5 Schedule

Construction of the KORE Power facility will include site preparation and the installation of

temporary facilities, security fencing, access roads, parking lots, and construction laydown

areas.

Clearing and grubbing will be followed by mass grading of the site. Building construction will

start with forming and pouring the concrete foundations. Wet and dry utilities will be brought to

the project site. Building and process structure erection will be initiated shortly thereafter. The

installation of mechanical systems and process equipment, as well as electrical and

instrumentation infrastructure, will be the final construction step, leading to commissioning and

the start of operations.

Phase 1 construction was initiated during the fourth quarter of 2022; construction completion is

anticipated in fourth quarter of 2024.

5

Up to 1,000 new jobs are anticipated during construction.

KORE Power will be responsible for compliance with federal, state, and local laws and

regulations, including, but not limited to, the Clean Air Act, Clean Water Act, National Historic

Preservation Act, and Endangered Species Act. The City of Buckeye will issue building permits

in accordance with City and Maricopa County codes and ordinances. The general contractor will

be responsible for compliance with permits for construction, including, but not limited to, a dust

control permit from the Maricopa County Air Quality Division (MCAQD) and stormwater pollution

prevention permits issued by the Arizona Department of Environmental Quality (ADEQ). A list of

the permits that have been completed or are in process is included in Appendix A, List of

Permits.

2.2 Operations

2.2.1 Personnel

The KOREPlex facility is anticipated to require approximately 1,500 employees for operation of

Phase 1 buildout. Preliminarily, the facility will operate on two 12-hour shifts per day, 7 days per

5

DOE issued a memorandum entitled Allowable Interim Actions under NEPA Review – KORE Power (Loan #A1017)

on November 28, 2022, which contemplated the initiation of construction activities prior to completion of the NEPA

review process.

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 11

week, with personnel rotating 36-hour and 48-hour work weeks. Buildout of Phase 2 will support

an estimated 3,000 employees on the same rotating schedule.

2.2.2 Traffic and Transportation

Phase 1 of the project is anticipated to generate approximately 100 truck trips per day plus

employee trips. Raw material deliveries will enter the site via the Rooks Road entrance on the

east side of the facility. After passing through a guard station, deliveries will be directed to the

truck bays at the east end of the manufacturing facility. Chemical deliveries and supplies will be

transferred to fixed tanks located within the secondary containment area along the delivery

route on the south side of the building. Shipping of the outgoing product will occur at the truck

bays on the west end of the manufacturing facility.

The primary truck access route to and from the site will be the north access driveway from

Rooks Road to MC 85 and then to SR 85 at the existing signalized intersection. The west

access driveway, with right-in/right-out traffic movements to SR 85, will be the primary route for

employee and visitor access. When SR 85 ultimately transitions to a limited access freeway, it is

anticipated that access along the western edge of the site will connect to a frontage road.

2.2.3 Production

Generally, battery cells comprise three primary components: electrodes (anodes and cathodes),

electrolytes, and separators. Battery cells can be packaged into different form factors (or

shapes) and then sold individually as battery cells or assembled into modules, battery packs, or

larger configurations (refer to Appendix B, Battery Basics).

By using various materials and chemicals for the primary components, batteries can be tailored

for different applications. KORE Power proposes to manufacture lithium-ion battery cells, using

nickel-manganese-cobalt (NMC) in pouch form and/or lithium-iron-phosphate (LFP) chemical

configurations in prismatic forms. The NMC and LFP batteries may be assembled into modules

and packs and integrated into e-mobility products and/or used for utility-scale energy storage.

Although the aforementioned chemistries and form factors are anticipated, research into battery

systems continues; the KORE Power facility may adjust or change its production lines to match

innovative technologies and developments in the future.

The battery production process is highly automated and precise. Many of the individual steps,

as well as much of the production line, include internal or external recycle functions that

eliminate and/or substantially reduce waste streams. Control equipment will be installed where

appropriate to maintain air quality standards.

6

Production will also include quality assurance and

quality control measures to meet performance requirements and ensure product stability and

safety. The process steps generally include:

Production of the electrode

Assembly of the battery cell

Battery formation

Module assembly

The production sequence and major equipment required for the battery cell manufacturing

process are outlined herein.

6

See the additional discussion of air quality control measures in Section 3.2.2

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 12

Electrode Production

Mixing

Raw materials, such as conductive additives, solvents, and binders, are mixed in a dry form and

then combined with liquids to form the cathode slurry, anode slurry, and ceramic slurry (Figure

4).

Figure 4 Mixing

Unifor

m distribution of the components, along with monitoring parameters such as viscosity,

density, and solid content, is directly related to the quality of the battery. The process will be

fully enclosed to avoid gas inclusions and control dust and moisture. Particulate-matter (PM)

emissions generated from the mixing process will be abated with the use of dust collectors.

Coating

As depicted in Figure 5, slurries generated from the mixing step will be evenly spread onto the

current collectors (typically copper and aluminum foils) and dried (Figure 6). NMP solvent will be

used as part of this process; solvent vapors will be abated with use of an exhaust gas recovery

device. Following coating and drying, the collectors will be wound into coils before proceeding to

the roll pressing operation.

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 13

Figure 5 Coating

Figure 6 Drying

Roll Pressing

The coated copper or aluminum foil will be compressed by a pair of rollers (Figure 7). The

electrode foil will be statically discharged and cleaned by brushes or air flow. The material will

be compacted by the top and bottom rollers.

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 14

Figure 7 Roll Pressing

Notching/ Slitting

Typically, rolls are fed to a slitting station in which a wide electrode coil (mother roll) is divided

into several smaller electrode coils (daughter rolls). The individual daughter rolls are then

cleaned and rewound. Figure 8 depicts the general notching and slitting process for both pouch

and prismatic-/cylinder-form batteries.

Figure 8 Notching/ Slitting

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 15

Cell Assembly

Die Cutting and Stac

king

The separated electrode sheets will be fixed with adhesive tape or glue and shear cut with a

punching tool (Figure 9) before being stacked in a repeating cycle of anode, separator, cathode,

separator, etc. (Figure 10). PM emissions generated from the cutting process will be abated by

the dust collector.

Figure 9 Die Cutting

Figure 10 Stacking

Welding, Packing, and Sealing (Pouch)

The current collectors (anodes and cathodes) will be connected to cell tabs using an ultrasonic

or laser welding process (Figure 11). The cell stack will then be positioned in a pouch and

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 16

sealed on three sides (typically). One side of the cell will be left open to add electrolyte. PM

emissions from welding will be abated by the dust collector.

Figure 11 Welding

Baking

Cells will be placed in a large oven and dried at high temperature and under vacuum to control

moisture and oxygen.

Electrolyte Filling

As depicted in Figure 12, the electrolyte will enter the cell, which is under vacuum, with help

from a high-precision dosing needle. The liquid electrolyte consists of organic carbonates that

generate volatile organic compound (VOC) emissions. VOC emissions will be abated by carbon

beds.

Figure 12 Electrolyte Filling

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 17

The cell will al

so get activated (wetted) by applying pressure and relying on the capillary effect.

Finally, the pouch foil will be sealed under vacuum.

Formation

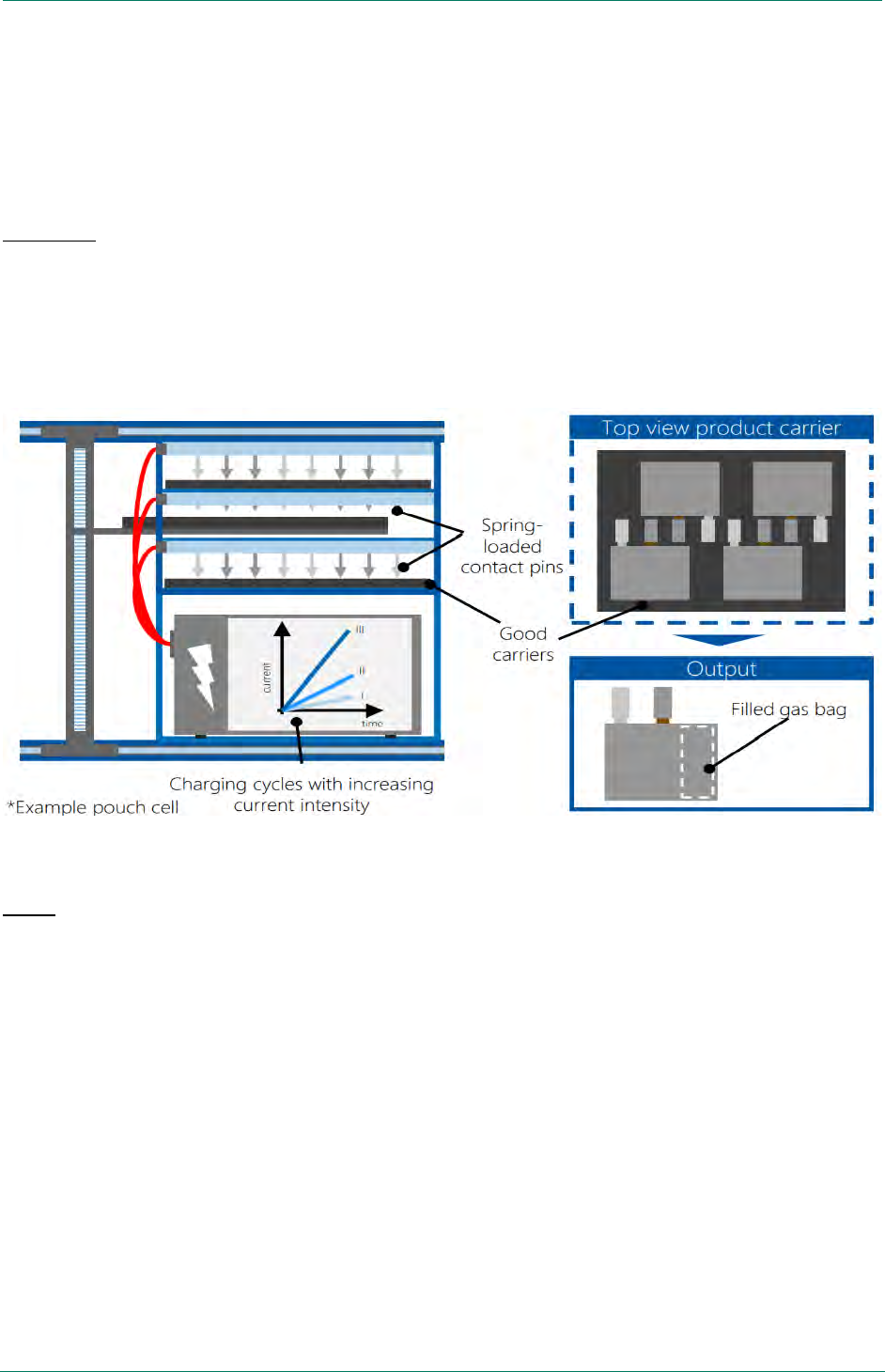

Formation

The cells will be activated for the first time by charging and (possibly) discharging during the

formation step (Figure 13). Defined currents and voltages will then applied to embed lithium ions

in the anode and establish an interface layer between the electrolyte and the electrode (the solid

electrolyte interface).

Figure 13 Formation

Aging

The aging process will be used for quality assurance; cell characteristics and performance will

be monitored and measured (Figure 14).

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 18

Figure 14 Aging

Degassing and Sealing

Off gases can be produced during the first charging of a cell; the gases will be collected in a

vacuum chamber for removal and treatment. Following degassing, the cell will be sealed under

vacuum, and the gas bag will be separated and properly disposed of. As needed, final folding

and gluing will be conducted to reduce the dimensions of the pouch cell. These steps are

depicted in Figure 15.

Figure 15 Degassing and Sealing

Grading

Grading is used to determine cell quality by analyzing data such as capacity, internal resistance,

and voltage drop over time (Figure 16). Testing of the cells may include pulse tests, internal

resistance measurements, visual inspections, voltage tests, and leakage tests.

KOREPlex Facility Environmental Assessment

Description of the Proposed Action

Page 19

Figure 16 Grading

Module

Assembly

Sorting

After testing, cells will be grouped according to their performance data. Cells that do not meet

performance specifications will be sent to recycling.

Module Assembly and Pac

king

Once the tests have been completed and passed, the cells will be packed and shipped or

integrated into battery energy storage systems.

2.2.4 Waste Management

Lithium-ion battery production is inherently a closed system that produces little to zero waste

material. Waste materials within the system are recycled back into the process to maintain

efficiencies. Defective cells (with or without electrolyte) are identified at several steps in the

process; these make up the majority of the solid waste generated by the production process.

Generally, the defective cells will be recycled. Other solid wastes generated by the production

process include electrode sheet and/or separator scrap, cutoff or defective pieces, and

aluminum-plastic film cutoff from the welding and packing step. Solid waste that cannot be

recycled will be disposed of at an appropriate facility.

During operations, isolation tanks/cases for the management and control of defective cells will

be staged throughout the production line, with smaller cases located more frequently and sized

to handle individual cells. Larger isolation tanks will be established for the different steps in

production. The isolation tanks/cases will eliminate potential risks from defective cells and be

appropriate to the corresponding stage of production.

The KOREPlex facility will generate both solid and liquid hazardous and non-hazardous waste

from manufacturing processes. Solid non-hazardous waste is generally associated with routine

building operations and maintenance. The storage, transport, recycling, and disposal of waste

material will be in accordance with applicable federal, state, and local environmental

regulations. Section 3.7.3 provides additional information related to waste generation and

management.

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 20

3.0 ENVIRONMENTAL CONSEQUENCES

In each of the following sections, a specific resource area is addressed with both qualitative

and, where applicable, quantitative information to concisely describe the nature and

characteristics of the resource that may be affected by the project, as well as the potential

impacts (direct and indirect) on that resource from the project given proposed controls. A

conclusion regarding the significance of impacts is provided for each resource area.

Section 3.8, Cumulative Impacts, provides a review of the present and reasonably foreseeable

federal and nonfederal actions that may contribute to a cumulative impact when added to the

impacts of the project. The impacts of past actions were reviewed and are included as part of

the affected environment to establish the current condition of the resource (i.e., the baseline

condition) that may be affected by the project.

3.1 Aesthetics and Visual Resources

The project area is situated in the Buckeye Valley. The White Tank Mountains lie approximately

10 miles to the north (north of Interstate 10). The Gila River is roughly 3 miles to the south.

South of the river, the terrain rises slightly in the Buckeye Hills. The historic center of the City of

Buckeye is about 1.5 miles to the east.

Historically, the predominant land use in the City of Buckeye was agricultural production, which

was interspersed with industrial uses and residential development. Agricultural fields continue to

convert to industrial and residential uses. Existing and planned warehousing and manufacturing

uses tend to align along major transportation corridors. The northbound lanes of SR 85 border

the project area on the west, the Union Pacific Railroad forms the northern boundary, and the

Buckeye Canal lies adjacent to the south. Rooks Road forms the eastern boundary of the

project area.

South of the Buckeye Canal, a gas station, tire shops, truck and transport facilities, equipment

yards, and other enterprises front MC 85. A strip of similar, as well as agricultural, uses lie north

of the railroad and south of Baseline Road. Fertizona, a concrete batch plant, and the new

(under construction) APS Western Service Center lie west of the southbound lane of SR 85. A

residential property lies east of Rooks Road on the north side of the Buckeye Canal (at the

southeast corner of the project area) (Figures 1-3).

After construction, the site would contain manufacturing facilities and buildings, an electrical

substation, a water storage facility, retention ponds, and paved parking lots. A setback of 400

feet would separate facilities from adjacent roadways and other land. Exterior building materials

would include steel, glass, and concrete panels that would be designed to offer aesthetically

pleasing breaks in color and material across the face of each building. Landscaping would

consist of a variety of native, low-water-use, and desert-adapted plants. Trees would be

strategically placed to offer shade along walkways and cool parking lots, and understory

planting would be used to soften and connect the project to the ground plane. Plantings along

adjacent perimeter streets and at the entrance would be used to enhance the aesthetic appeal.

Because the area is zoned for industrial use, existing and planned manufacturing and other

industrial facilities are adjacent to the project area, and landscaping would be incorporated,

impacts on aesthetics and visual resources as a result of the project would not be significant.

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 21

3.2 Water Resources

3.2.1 Surface Water

The project area lies within the historic floodplain of the Gila River. The hydrology within the

study area has been altered by development, transportation structures, agriculture, and

irrigation features. The Buckeye Flood Retarding Structure system, constructed by the Flood

Control District of Maricopa County in 1975, parallels Interstate 10 and intercepts and diverts

stormwater runoff from the White Tank Mountains to the north. The Roosevelt Canal, located

approximately 2.3 miles north of the project area, prevents stormwater flows from south of

Interstate 10 from reaching the project area. The Union Pacific Railroad is located along the

northern boundary of the project area; the Buckeye Canal traverses the southern boundary. The

project area is composed entirely of agricultural fields; return flows are captured in a constructed

basin at the southwest corner. The project area receives negligible stormwater flows from

upgradient areas and does not contribute flows to downgradient areas. The drainage channel to

be constructed along the west side of the Rooks Road alignment is part of a recommended

regional solution for stormwater management (Dibble, 2009).

Floodplains

The project site is currently comprised of undeveloped agricultural land that generally slopes to

the south at a fall of approximately 0.7 percent. Under existing conditions, stormwater run-on

from off-site areas that may affect the project area are limited. Stormwater run-on tends to pond

along the north side of the Union Pacific Railroad, which parallels the northern boundary of the

site.

As depicted in Figure 17, the southern portion of the project area (along the Buckeye Canal) is

on a Federal Emergency Management Agency (FEMA) Flood Insurance Rate Map, Panels

0413C2580L and 0413C2115L (FEMA, 2013). The majority of the property is within Special

Flood Hazard Area “Zone X” (i.e., an area with a 0.2 percent annual chance of a flood hazard or

an area with a 1 percent annual chance of a flood with average depth of less than 1 foot or with

drainage areas of less than 1 square mile). The portion of the project area lying adjacent to the

Buckeye Canal is delineated as Special Flood Hazard Area “Zone AH” (i.e., an area with a 1

percent annual chance of shallow flooding, usually in the form of a pond, with an average depth

ranging from 1 to 3 feet). The base flood elevation for this portion of the project area is 881 feet.

Stormwater management for the KORE Power facility includes collection facilities (underground

piping and open channels) to convey stormwater runoff away from structures to retention areas.

Drywells would be constructed within the retention areas to facilitate the infiltration of ponded

water. The retention areas would also account for the volume of stormwater retained in the

project area prior to development, as mapped in FEMA Special Flood Hazard Area Zone AH. A

Conditional Letter of Map Revision would be submitted to revise floodplain mapping accordingly.

Construction activities would be conducted under an Arizona Pollutant Discharge Elimination

System Construction General Permit and a notice of intent would be filed with the ADEQ. As a

result of these detailed best management practices, a Stormwater Pollution Prevention Plan and

various on-site erosion and sediment controls, impacts to surface water resources, including

floodplains, would not be significant.

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 22

Figure 17 FEMA Flood Zones and National Wetlands Inventory

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 23

3.2.2 Groundwater

The average depth to groundwater in the project area is approximately 35 to 50 feet below the

ground surface (ADWR, 2022). Although KORE may provide locations for groundwater wells for

the City of Buckeye, construction and development of the well sites would be conducted by the

City. Therefore, the wells are outside the scope of analysis for this EA.

Excavation activities for the KORE Power facilities would not reach the depth of groundwater;

thus, the project would have no direct or indirect impact on groundwater. The manufacturing

process is not water-intensive; water to the facility would be provided by the City of Buckeye.

The KOREPlex facility would not have a direct impact on groundwater sustainability.

Furthermore, the conversion of the project area from agricultural use to manufacturing would

reduce the groundwater demand from the project area. Impacts to groundwater resources would

not be significant.

3.3 Air Quality

3.3.1 Setting

Air quality is determined by the ambient concentrations of pollutants that are known to have

detrimental effects on public health and the environment. In accordance with Section 109 of the

Clean Air Act, the U.S. Environmental Protection Agency (EPA) has promulgated National

Ambient Air Quality Standards (NAAQS) for six criteria pollutants: carbon monoxide (CO), PM,

lead, sulfur dioxide (SO

2

), ozone, and nitrogen oxides (NO

X

) (40 CFR 50). Standards for PM

exist for two categories of particles: those equal to or smaller than 10 microns in diameter

(PM

10

) and those equal to or less than 2.5 microns in diameter (PM

2.5

). Areas that do not meet

the air quality standards are designated as “non-attainment areas.” A designation of non-

attainment submits an area to regulatory control of pollutant emissions so that attainment of the

NAAQS can be achieved within a designated time period.

The EPA regulates emissions of air pollution from mobile and stationary sources under the

authority of the Clean Air Act. The MCAQD has jurisdiction over stationary air pollution sources

in the county and administers the permitting program pursuant to Part 70 of the Clean Air Act.

Operating permits issued by MCAQD are legally enforceable documents. They are designed to

improve compliance with the Clean Air Act by specifying control measures for facilities with the

potential to emit pollutants.

The project area is within Maricopa County, which is currently designated as an attainment area

with respect to the NAAQS, except for the 8-hour ozone and PM

10

standards (EPA, 2022a).

Specifically, the project area is in attainment for the NAAQS, except for the 8-hour ozone

standard. The non-attainment area for PM

10

is adjacent to the project area and to the east

(Figure 18).

3.3.2 Emissions Analysis

Air emissions would result from construction and operation of the proposed KOREPlex facility.

Generally, impacts on air quality from construction activities are considered short-term impacts,

lasting only for the duration of construction. Operational impacts are considered long-term

impacts, occurring while the facility is in use. Required permits, air quality standards, and the

consequences of the project on air quality are discussed below.

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 24

Figure 18 Air Quality

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 25

Construction

Air emissions resulting from development of the proposed facility would include fugitive dust

(PM

10

and PM

2.5

) associated with construction activities (e.g., earthmoving) and emissions from

vehicles and equipment (e.g., CO, SO

2

, NO

x

, precursors to ozone) may result in temporary

impacts to the Project site. To reduce emissions of pollutants, during construction, appropriate

construction best management practices would be implemented, and vehicles and equipment

would be properly maintained. Contractors would be required to comply with the best

management practices specified in the Dust Control Permit; additional measures to minimize

soil erosion and sedimentation are mandated under the Arizona Pollutant Discharge Elimination

System Notice of Intent/Construction General Permit, which would also minimize dust

generation. Because of the relatively short duration of air emissions associated with

construction, and the best management practices that would be employed, impacts on air

quality during construction would not be significant.

Operation

In accordance with the MCAQD Part 70 permit program, industrial operations that have the

potential to emit 5.5 pounds per day or 1 ton per year of any regulated air pollutant are required

to obtain an air quality permit to operate the facility. The type of permit issued by MCAQD

requires a detailed review of facility systems, projected emissions, and the current ambient air

quality. New manufacturing facilities must demonstrate use

and implementation of best

available control technology (BACT) to reduce emissions, as practicable.

Permits

set emission limitations and define monitoring, recording, and reporting requirements

and are valid for 5 years. Although an owner may revise and/or transfer an air quality permit,

continued operation of the facility

must be in accordance with the active permit.

Because the proposed facility would be a new stationary source with the

potential to emit

regulated pollutants, an application for a permit to operate is being prepared for submittal to the

MCAOD. Expected emissions from the KOREPlex manufacting process include:

PM emissions from the mixing stage

VOC emissions during the coating and drying stage

Hazardous air pollutant (HAP) emissions from chemical usage in die cutting

PM emissions during laser cutting (permit exempt)

VOC emissions during electrolyte filling

NO

X

, CO, VOC, PM

10

, PM

2.5

, SO

2

, and HAP emissions from natural gas combustion in HVAC

units

7

VOC emissions from storage tanks

KORE Power would use an exhaust gas recovery device with an estimated 95 percent control

efficiency to abate NMP emissions during cathode application, thereby meeting the BACT

requirement. Carbon beds with an estimated 95 percent control efficiency would abate VOC

emissions during the electrolyte filling process and from storage tanks, also in accordance with

BACT requirement. Dust collectors and carbon beds would comply with MCAQD regulations to

control visible emissions, fugitive dust and PM, and VOC emissions.

7

The KOREPlex facility is evaluating the efficiency of two approaches to climate control (i.e., air-conditioning and

heating): a combination of dehumidification and rooftop units or air handling units. In either case, natural gas

combustion would power the climate control systems. For the purposes of this analysis, 38 dehumidification units and

62 rooftop units are assumed to be necessary for cooling or heating the facility. If elected, the air handling units would

be anticipated to have lower emissions.

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 26

Based on information from the air permit application, Table 2 summarizes anticipated emissions

from continuous operation of the facility with BACT measures implemented. The anticipated

maximum emissions of all pollutants would be below the MCAQD permit threshold for a Major

Facility (Class I). As such, a Class II permit issued by the MCAQD would be applicable for long-

term operation of the facility. Compliance with permit conditions would prevent pollutant levels

from exceeding the NAAQS within non-attainment areas.

Table 2. Estimated Facility-Wide Emissions

Source

Pollutant

Controlled

Emissions

(pounds/year)

Controlled

Emissions

(tons/year)

Major Facility

Threshold

(tons/year)

Natural gas combustion NO

X

21,000 11 100

Natural gas combustion CO 5,800 2.9 100

Natural gas combustion, cathode

application, Line 1 electrolyte filling, Line

2 electrolyte filling, storage tanks

VOCs 25,000 13 100

Natural gas combustion, anode mixing

(Line 1 & 2), cathode mixing (Line 1 & 2)

PM 1,200 0.60 100

Natural gas combustion, anode mixing,

cathode mixing (Line 1 and 2)

PM

10

1,200 0.60 70

Natural gas combustion SO

2

100 5.0 x 10

-2

100

Natural gas combustion Benzene 1.3 6.6 x 10

-4

10

Natural gas combustion Formaldehyde 2.8 1.4 x 10

-3

10

Natural gas combustion Total PAHs (exc.

naphthalene)

0.02 8.2 x 10

-6

10

Natural gas combustion Naphthalene 0.05 2.5 x 10

-5

10

Natural gas combustion Acetaldehyde 0.71 3.5 x 10

-4

10

Natural gas combustion Acrolein 0.44 2.2 x 10

-4

10

Natural gas combustion Ammonia 530 0.27 10

Natural gas combustion Ethylbenzene 1.6 7.8 x 10

-4

10

Natural gas combustion Hexane 1.0 5.2 x 10

-4

10

Natural gas combustion

Toluene

6.0

3.0 x 10

-3

10

Natural gas combustion Xylene 4.5 2.2 x 10

-3

10

Cathode mixing Cobalt

compounds

0.53 2.6 x 10

-4

10

Cathode mixing Nickel

compounds

0.53 2.6 x 10

-4

10

Cathode mixing Manganese

compounds

0.53 2.6 x 10

-4

10

Die cutting

*

Acetonitrile 18,000 9 10

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 27

Source

Pollutant

Controlled

Emissions

(pounds/year)

Controlled

Emissions

(tons/year)

Major Facility

Threshold

(tons/year)

Natural gas combustion, cathode mixing,

die cutting

Total HAPs 19,000 9.5 25

ERM, 2022. The estimated emissions assume continuous operation of the KOREPlex facility (8,760 hours/year).

*An alternate die-cutting process, using tape in lieu of acetonitrile, is under evaluation, which would eliminate this

potential emission.

PAH = polycyclic aromatic hydrocarbon

Through implementation of BACT measures and compliance with the MCAQD Class II Minor Air

Quality Permit, the impact on air quality within the analysis area would not be significant.

3.4 Biological Resources

This section describes biological resources that may be affected by implementation of the

project, including vegetation, wildlife, and special-status species.

3.4.1 Vegetation

The project area lies within the Lower Colorado River subdivision of the Sonoran desert scrub

biotic community, as defined by Brown (1994). The project area comprises fallowed fields, most

recently planted in alfalfa (Medicago sativa), and structures used for irrigation and agricultural

operations, (e.g., canals, roadways). Negligible native vegetation is present. A retention pond in

the southwest corner holds return agricultural flows; however, wetland plants are not present.

3.4.2 Wildlife

The project area provides habitat for many species of wildlife. Mammals known to exist within

the vicinity include coyote (Canis latrans), desert cottontail (Sylvilagus audubonii), black-tailed

jackrabbit (Lepus californicus), and round-tailed ground squirrel (Spermophilus tereticaudus).

Lizard species in the vicinity include tiger whiptail (Aspidoscelis tigris), side-blotched lizard (Uta

stansburiana), and Gila monster (Heloderma suspectum). Snakes in the area include western

diamondback rattlesnake (Crotalus atrox) and gophersnake (Pituophis catenifer). Several bird

species are known to occur in the project area, including western burrowing owl (Athene

cunicularia). Detailed information regarding these special-status species can be found in the

Migratory Birds section, below.

Agricultural lands, as well as the retention pond for agricultural return flows, serve as foraging

habitat for wildlife in the project area. Construction would remove land used as foraging habitat

for wildlife, including bird species; however, these individuals would most likely relocate to

adjacent fields and retention ponds. Direct mortality of a few mammals and reptiles may occur

during construction, although the grading and soil disturbance that would occur would be similar

to normal agricultural practices. Construction could temporarily disturb wildlife species that use

habitat adjacent to the project area; however, this disturbance is not expected to be substantial

because loud ground-disturbing activities are common in agricultural lands. Wildlife generally

leave an area upon initial construction. Therefore, the impacts on vegetation, wildlife, and wildlife

populations would not be significant.

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 28

Special-Status Species

Threatened and Endangered Species

Threatened and endangered species and their critical habitat that have the potential to occur in

the project area were evaluated (Appendix C, Screening Analysis for Threatened and

Endangered Species). The evaluation concluded there would be no effect on threatened or

endangered species or their critical habitat from implementation of the project.

Migratory Birds

Migratory birds are protected under the Migratory Bird Treaty Act. Migratory birds observed in

the project area include western burrowing owl, Gambel’s quail (Callipepla gambelii), killdeer

(Charadrius vociferus), red-winged blackbird (Agelaius phoeniceus), yellow-headed blackbird

(Xanthocephalus xanthocephalus), great-tailed grackle (Quiscalus mexicanus), great blue heron

(Ardea herodias), great egret (Ardea alba), mallard (Anas platyrhynchos), and black phoebe

(Sayornis nigricans). The majority of the birds were using the retention pond in the southwest

corner of the project area. Western burrowing owls located on the banks of the irrigation ditches

used irrigation pipes in the agricultural fields for cover prior to site grading. Because of grading,

the project area is not considered suitable breeding habitat for birds. Killdeer and western

burrowing owls are the exception; both of these species nest in or on the ground in disturbed

areas.

Site-specific surveys were conducted for western burrowing owl prior to ground-disturbing

activities. A federally permitted biologist conducted the surveys in conformance with the protocol

outlined in the Arizona Game and Fish Department (AGFD) Burrowing Owl Project Clearance

Guidance for Landowners. Several pairs of burrowing owls, as well as active burrows, were

identified on or adjacent to the site during the survey. A Migratory Bird Special Purpose Permit

was obtained through the U.S. Fish and Wildlife Service (USFWS) for relocation of the owls and

destruction of the nests. Owls were trapped, and active and potential burrows were collapsed

on-site and along the berms of the irrigation canal immediately adjacent to the site, according to

USFWS guidelines.

Fliers regarding western burrowing owl were provided to construction contractors and posted at

the project site for continued management. If an owl cannot be flushed and is in the path of

construction, work should stop until the owl flushes or until a permitted biologist arrives to

evaluate and resolve the situation. A biological monitor would be provided during initial

construction and for future stages of the project if new burrowing owl activity is detected.

With implementation of preconstruction efforts by permitted biologists to remove and relocate

western burrowing owl from the subject site, impacts would be considered negligible and short

term. It is not anticipated that western burrowing owl would occupy active developed portions of

the project area. Should owls repopulate berms on existing canals or retention basins, KORE

Power operations would not be anticipated to affect these individuals. Based on these

considerations, impacts on migratory birds from the project would not be significant.

3.5 Cultural Resources

3.5.1 Historic Properties

A qualified archaeological consultant conducted a Class I site file search and literature review

covering a 1-mile radius around the area of potential effect (APE) and a Class III cultural

resources inventory of the project site (Paleowest, 2022). The archaeological APE consists of a

213.8-acre parcel of farmland, which is situated entirely on private land. The architectural APE

(i.e., site file search radius) consists of the 213.8-acre project footprint as well as a 1-mile buffer

surrounding the area to address potential indirect effects. The survey of the APE identified one

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 29

site, one isolated occurrence, and two in-use historic structures. The identified site includes

historic building foundations and a well that was associated with historic agricultural/farming

practices in the area. The isolated occurrence is a capped well of unknown age. One in-use

historic structure is made up of lateral segments of an irrigation canal, along with roads

associated with farming in the region. The other in-use historic structure is a segment of the 69-

kilovolt transmission line from Buckeye to Gillespie that parallels the eastern edge of the project

area. None of these sites are considered eligible for listing on the National Register of Historic

Places or Arizona Register of Historic Places, and no avoidance measures are recommended

for ground-disturbing activities.

No historic architectural structures, historic areas, or archaeological sites are present within the

project area. On June 9, 2022, a consultation letter was sent to the Arizona State Historic

Preservation Office (SHPO) for Section 106 consultation, requesting concurrence with the

archaeological and architectural APEs, as well as the DOE review and finding of no historic

properties affected. On October 31, 2022, SHPO concurred with the recommendations in the

Class III survey that no archaeological resources in the APE are eligible for listing in the NRHP.

Should unexpected archaeological resources be discovered during construction, activities would

be halted in the immediate area of the discovery until the resources have been evaluated for

NRHP eligibility criteria (36 CFR 60.4) in consultation with the SHPO, Arizona State Museum,

DOE, and/or interested tribal consulting parties, as appropriate, and in accordance with 36 CFR

800.13. Appropriate mitigation would be determined during this consultation.

Due to the absence of eligible architectural and archaeological resources within the APE, the

controls that are in place in the event of an unanticipated discovery, and the SHPO’s

concurrence on the archaeological and architectural findings, impacts on cultural resources as a

result the project would not be significant.

3.5.2 Consultation with Native American Tribes

In conjunction with this EA and the National Historic Preservation Act Section 106 historic and

archeological review process, DOE sent a June 2022 NEPA notice regarding the KORE Power

project to Native American tribes in an effort to identify tribal interest in the project site and

provide an opportunity to make comments or express concerns. The following federally

recognized tribes and councils were contacted (see Appendix D, Consultation with Agencies

and Native American Tribes):

Ak-Chin

Colorado River Indian Tribes

Fort McDowell Yavapai Nation

Fort Mojave Indian Tribe

Gila River Indian Community

Hopi Tribe

Mescalero Apache Tribe

Pascua Yaqui Tribe

Pueblo of Zuni

Salt River Pima-Maricopa Indian Community

San Carlos Apache Tribe

KOREPlex Facility Environmental Assessment

Environmental Consequences

Page 30

Tohono O'odham Nation

White Mountain Apache Tribe

Yavapai Apache Nation

Yavapai Prescott Indian Tribe

Following submission of the notice, each tribe was contacted by telephone to ensure receipt and

respond to any immediate questions or concerns. No immediate concerns were relayed by the

tribes. Next, the DOE contacted the aforementioned tribes upon completion of the cultural

resources survey for the project site. The Pascua Yaqui Tribe, Tohono O'odham Nation, Gila

River Indian Community, and White Mountain Apache Nation requested a copy of the cultural

resources survey for review. All of the aforementioned tribes that reviewed the survey concurred