Unclassified NEA/CSNI/R(2009)5

Organisation de Coopération et de Développement Économiques

Organisation for Economic Co-operation and Development

17-Dec-2009

___________________________________________________________________________________________

English text only

NUCLEAR ENERGY AGENCY

COMMITTEE ON THE SAFETY OF NUCLEAR INSTALLATIONS

STATE-OF-THE-ART REPORT ON NUCLEAR AEROSOLS

JT03276300

Document complet disponible sur OLIS dans son format d'origine

Complete document available on OLIS in its original format

NEA/CSNI/R(2009)5

Unclassified

English text only

NEA/CSNI/R(2009)5

2

NEA/CSNI/R(2009)5

3

THE GROUP HAVING PREPARED THIS SOAR CONSISTED OF

Hans-Josef Allelein GRS, Germany

(Chairman)

Ari Auvinen VTT, Finland

Joanne Ball AECL, Canada

Salih Güntay PSI, Switzerland

Luis Enrique Herranz CIEMAT, Spain

Akihide Hidaka JAEA, Japan

Alain V. Jones formerly JRC Ispra, EC

Martin Kissane IRSN, France

Dana Powers SNL, USA

Gunter Weber GRS, Germany

NEA/CSNI/R(2009)5

4

ANNOTATION ON THE REFERENCES

The reader will find a list of references at the end of each sub-chapter. The advantage of this is close

connection between written text and the quoted reference, the disadvantage is that some references are

listed more than once in the whole report.

The authors hope the advantage will outweigh the disadvantage.

NEA/CSNI/R(2009)5

5

EXECUTIVE SUMMARY

Background

Nuclear aerosol investigations began in the late 1960s and early 1970s. The progress made both in

experimental studies and in code development is attested to by the publication of three CSNI-sponsored

State-of-the-Art Reports (SOAR) on nuclear aerosols since 1979. Initially, fast reactor safety was the main

concern of the work, as reflected in the content of the first aerosol SOAR. The TMI accident in 1979

motivated an interest in LWR source terms and resulted in the production of a supplement to the first

SOAR which concentrated on LWR aerosol issues. In contrast to the fast reactor situation, the large

quantity of steam present in the LWR containment atmosphere following an accident tends to make aerosol

particles more compact, reducing the modelling problem of defining shape factors. On the other hand, two

new effects had to be modelled: deposition due to steam condensation onto surfaces (diffusiophoresis) and

particle growth by steam condensation onto the particles themselves.

The second SOAR dealt with primary-system fission-product release and transport. This SOAR included a

survey of the models available in the literature for homogeneous and heterogeneous nucleation, for vapor

condensation on aerosols, and for aerosol agglomeration, and noted that these and other models had been

incorporated in circuit codes.

The last workshop on aerosols organised by the OECD was held in Cologne in June 1998. One

recommendation made at this workshop was to prepare a SOAR on aerosol behaviour in both the primary

circuit and in containment.

Objectives

Following the recommendation of the Cologne workshop, the CSNI mandated the preparation of a SOAR

with four main objectives:

• To assess the status of existing experimental data and analytical capabilities required for predicting

aerosol source terms from LWR accidents

• To address the strengths and weaknesses of the codes used to predict aerosol behaviour in the

reactor coolant circuit and containment, and provide validation results and uncertainties, in

particular for plant applications,

• To summarise findings from recent ISP exercises on nuclear aerosols and related thermal-hydraulic

behaviour in the reactor coolant circuit and containment.

• To identify safety-relevant pending issues and to propose research activities that will reduce gaps in

the understanding of relevant processes and deficiencies in modelling capabilities.

Scope

The Nuclear Aerosol Writing Group met several times over a three-year period from 2003 to 2006 to

prepare the current SOAR, which provides a survey of issues surrounding the prediction of nuclear aerosol

behaviour in the primary system and containment. It should be noted that the subject matter of the report is

NEA/CSNI/R(2009)5

6

limited to nuclear aerosols and does not extend to other LWR accident source term topics that do not have

a direct bearing on aerosol behaviour.

The structure of this SOAR is in line with the objectives listed above. The introduction is followed by a

background chapter discussing the fundamentals of aerosol behaviour with bibliography of the pertinent

literature. Chapter 3 is devoted to the topics of aerosol formation/growth, transport, and retention and

release. Chapter 4 provides descriptions of codes for modelling circuit and containment aerosol behaviour,

and Chapter 5 describes the experiments used for their validation. Chapters 6 and 7 provide examples of

validation results, and plant applications of source term calculations. Chapter 8 summarises the findings of

the Cologne Workshop and progress made since, and provides recommendations for future work.

Results and their significance

The theoretical, experimental and modelling studies presented in this SOAR summarise the status and

current understanding of a wide range of nuclear aerosol topics. The significance of these results is that

they allow for the identification of existing gaps in code capability and experimental data that prevent

accurate predictions of the source term. A general conclusion from this document is that there still exist a

number of items for which additional work is required. However, the status of aerosol codes and

experimental data-bases has improved substantively since the publication of previous SOARS.

At the time when the 1994 SOAR on circuit aerosols was written, plant analysis codes, (as distinct from

special-purpose research tools) were relatively crude, and their validation base was largely confined to tests

using simulant materials. Now, while these codes still use lumped-parameter descriptions of the thermal

hydraulics that can place some constraints on the accuracy of their predictions, they include a more

complete calculation of gas-phase chemistry, interactions with particles and surfaces in the primary circuit,

and a better treatment of coupling between aerosol dynamics and thermal hydraulics in the containment.

Models are also available for aerosol interactions with engineered safety features such as suppression pools

in BWRs, and complex structures such as steam generators in PWRs.

The experimental database for development and validation of aerosol codes has benefited from more

accurate and extensive instrumentation to measure a wider range of phenomena (e.g., the ability to measure

airborne water). Numerous analytical tests have been performed, and are continuing, to address specific

phenomena such as resuspension, revaporisation, and trapping in complex structures. Large-and

small-scale containment aerosol experiments have also been performed and analysed in international

programmes, notably the KAEVER and VANAM tests. Perhaps the most significant advance on the

experimental side is the availability of integral experiments in the PHÉBUS facility on fission product and

structural material release and transport. These tests demonstrate the complex inter-linkage between

different phenomena and have refined our understanding of nuclear aerosols, particularly in the circuit,

where we are now able to refer to measured particle sizes and compositions. PHÉBUS has also provided

information on specific phenomena such as revaporisation. The PHÉBUS integral experiments are now

complete but post-test analyses and interpretation of the results continues. Data from aerosol-related

experimental programmes such as ARTIST and THAI also still require analysis.

A large number of Probabilistic Safety Analyses (PSA2) plant studies have been performed around the

world, frequently involving aspects of aerosol behaviour. This report provides some examples, including

sensitivity studies that demonstrate the impact of aerosol-related processes, however few such analyses

have been published. The aerosol community is therefore not always fully briefed on the risk-relevance of

the numerous phenomena currently under study. The question of risk significance deserves a more

concerted effort, in aerosol physics as in other relevant fields. This will require additional probabilistic

analysis for new plant designs and evaluation of their sensitivity to various models and parameters.

NEA/CSNI/R(2009)5

7

It is expected that increasingly stringent safety standards and new power reactor designs will generate

aerosol-related safety questions that will require experimental capabilities, analytical tools, and the

expertise to use both intelligently. Aerosol-related computational and modelling capability is now being

utilised to address industrial problems, and major environmental issues such as climate change are

producing a body of knowledge that should be integrated with that developed within the reactor safety

community. The CSNI structure appears well suited to developing structures and mechanisms for

stimulating such cross-fertilisation.

Conclusions and recommendations

A number of conclusions and recommendations have been made throughout the text of this document. The

most important are summarised briefly below subdivided into three categories

Generic Issues

Code-users’ workshop on plant analysis: The CSNI workshop recommended in 1998 that a meeting on

the use of severe-accident codes in plant calculations for source term estimation, including codes used by

utilities, be held. More than eight years after formulation of this recommendation it has still not been acted

upon. There remains a need to harmonise user practices with respect to plant analyses in order to reduce

divergence in results. The objective would ideally be to produce online “best practice” guidelines for the

major codes.

Shape factors: Models describing aerosol dynamics generally assume spherical, fully dense particles but

nuclear aerosols are often neither, particularly those originating from core melt sequences, or accident

scenarios in which large parts of containment have low humidity. The importance of shape factors has been

demonstrated in uncertainty and sensitivity analyses. Although such parametric studies can be performed

for accident scenarios, the difficulty is in knowing what constitutes a “reasonable” variation of the shape

factors for representative conditions. At the minimum, it is recommended that measurements of two

diameters (e.g., aerodynamic and volume-equivalent diameter) of aerosols from prototypical integral

experiments be obtained to determine the dynamic shape factor.

Reactor Coolant System Issues

Analytical support by the use of CFD Codes: CFD treatment of coupled aerosol/flow phenomena is not

universal because of the complexity of the phenomena and geometries, and the effort required for

implementation. At present, efforts are being made to simulate particle transport and deposition in complex

reactor structures with CFD, however more work needs to be done this treatment becomes satisfactorily

accurate.

Mechanical Resuspension: Existing models are inadequate to evaluate the safety impact of aerosol

resuspension in the primary circuit, which is both design- and scenario-dependent. Experiments are

required for the development and validation of models to: a) account for the porosity of a deposit, which

affects the mass and size distribution of resuspended material and b) simulate the effect of shock and

vibrations (alone and in combination with flow increases) on resuspension. There is also limited work on

the resuspension of wet deposits or wet deposits which have dried in situ. It is recommended that scoping

calculations be performed to assess the potential impact of this behaviour on the source term. Finally, it has

to be said that the consequences for a severe accident of a light-water reactor due to resuspension from the

RCS varies depending on the scenario, i.e., bypass or non-bypass sequences. For non-bypass sequences,

the influence of this resuspension on the potential source term may well be insignificant within a few

hours. However, improvement of resuspension modelling with respect to bypass sequences is clearly very

desirable.

NEA/CSNI/R(2009)5

8

Deposition in singularities and complex structures: No significant advances appear to have been made

since 1998 in the experimental investigation or the modelling of deposition in singularities such as changes

in cross section or bends. Some code improvements have been made by including the best-available

models from published literature.

Significant progress has been made with respect to deposition in steam generators (SGs). Most

probabilistic risk assessments (PRAs) and severe accident codes assume that a significant fraction of

fission products flowing through an non-isolated break in a SG escapes to the environment. This may not

be the case however, as demonstrated in several recent experimental programmes. SGTR was the first

European project (2000-2002) to improve understanding in a systematic way of possible retention

mechanisms in tubes and in the complex structures of the secondary side of a SG. In particular, the

PSAERO and HORIZON experiments from Finland were conducted to study in-tube retention whereas

retention in the SG bundle has been investigated in PECA-SGTR and the ongoing ARTIST experiments

(respectively in Spain and Switzerland). In addition, certain modelling efforts to develop a correlation for

the retention in the bundle were initiated. Thorough interpretation of the data from the above experiments

is incomplete and modelling efforts continue. It is expected that the main issues regarding SGTR will be

answered after termination of these activities.

Particle break-up in highly turbulent flows: Highly turbulent flow inside a tube may induce break-up of

particles due to (i) impaction on the walls, (ii) strong shear in the flow or (iii) the vena contracta and shock

wave at the tube exit. This phenomenon was observed, e.g., in Phase I of the ARTIST tests as well as in

supplementary experiments. However, to determine whether aerosol particles may break up in severe

accidents would require more information on the structure and the nature of the bonding forces between

primary particles for severe accident aerosols as well as for the TiO

2

agglomerates used in ARTIST Phase

I. In Phébus tests, which produced more prototypical aerosols, SEM micrographs showed fairly compact,

sintered agglomerate structures unlike the ARTIST TiO

2

particles. Consequently, intra-particle forces can

be expected to be higher in reality than in these TiO

2

agglomerates. Nevertheless, the issue is of some

importance since the generation of submicron particles from supramicron ones leads to less-efficient

retention of the aerosols concerned. In the first instance, accident sequences other than SGTR inducing

highly-turbulent flows need to be identified; comparison of plant calculations without and with (assumed)

break-up for SGTR and the other pertinent sequences would then allow evaluation of the risk relevance of

the break-up phenomenon. If the risk impact is significant then, in the absence of relevant data for severe

accident aerosols, data for prototypical particles are needed in highly-turbulent accident-relevant

conditions.

Impact of Chemistry: The fundamental importance of chemistry to prediction of source terms arising from

potential severe accidents is well established. Nuclear safety codes model chemical reactions using the

thermodynamic equilibrium approach, which relies on having thermodynamic data for each chemical

species covered. Unfortunately, the uncertainties associated with some of these data are often large and

divergence between data series originating from different sources can be considerable. It is recommended

(as is being done for the ASTEC code) that the thermo-chemical data used by codes be thoroughly verified

and that key sources of uncertainty be identified. Moreover, while the thermodynamic approach is

pragmatic, it is of limited value when addressing accident scenarios in which slow chemical kinetics

precludes achievement of thermodynamic equilibrium (e.g. secondary-side, cold-leg and containment

conditions). In this context it is recommended to:

• Assess the value of the simplistic approach (taken in ASTEC/SOPHAEROS and VICTORIA codes)

of assigning user-defined cut-off temperatures below which chemical reactions in the RCS do not

occur. Use of PHÉBUS FP results with respect to iodine in the RCS should prove helpful;

• Follow closely experimental programmes that are investigating reaction rates for iodine species

(e.g., the French CHIP series).

NEA/CSNI/R(2009)5

9

• Assess whether FP species other than iodine, which may reach the containment in the vapor phase,

require kinetic modelling (especially important for hot-leg and high-pressure sequences where vapor

fractions at the RCS breach will be significant).

• Lastly, the effects of radiolysis in the RCS are unknown. Radiolysis may have little impact in the

core region (temperatures being so high that only simple atomic and radical species exist), but may

be important in cooler regions of the RCS involving significant deposits (high local dose rate) such

as in a cold-leg sequence. In terms of direct consequences for aerosols, one effect will be reduction

of the threshold super-saturation at which vapors nucleate since a high density of

electrically-charged condensation nuclei will form. In terms of consequences for the source term, the

meagre state of knowledge renders even qualitative evaluation difficult.

Revaporisation of deposits: Although significant progress has been made regarding studies on

revaporisation from several projects (Phébus FP, the EC 4th Framework Programme projects RVP and

REVAP-ASSESS and the EXSI project), experimental work on revaporisation remains scarce; further

theoretical and experimental developments are necessary to understand the revaporization process. In

addition, the safety relevance ought to be further demonstrated by assessing, conceivably, the impact of a

weak source of fission products from the reactor coolant system for some hours after the main

release-from-core phase.

Containment Issues

Charge effects: Small deposits of aerosols on the outer walls of the 10 m

3

containment vessel in the

PHÉBUS test FPT0 could not be explained by electrophoretic effects. However, even if charge effects on

aerosol deposition are not seen to be significant in test facilities (with or without a radiation field) there is

no firm evidence that this effect would be negligible in an accident. At present there is no consensus

among experts on whether further investigations of charging effects are necessary or not.

Mixed aerosols in condensing atmospheric conditions: Although there has been considerable progress in

modelling aerosol deposition as a function of relative humidity, a comparison of the adequacy of code

results from ISP 37 and ISP 44 indicate that there is still some work to be done to ensure satisfactory

coupling between thermal hydraulic and aerosol models so that these capture correctly aerosol behaviour in

most environments. An additional uncertainty in modelling aerosol behaviour in the containment in humid

conditions arises from determining the hygroscopicity associated with a mixture of aerosols of different

compositions. Finally, there is some uncertainty regarding the density of multi-component aerosols, and

whether this parameter is important for accident conditions with a wide variety of aerosol components.

Both the PHÉBUS tests and the KAEVER experiments suggest that an average aerosol particle

composition and size might be attained in containment. The KAEVER experiments further suggest that this

average particle would behave like the most hygroscopic of its individual components. Confirmation of

these findings, in a large- or intermediate-scale experiment performed under saturated conditions might

significantly simplify modelling aerosol behaviour in wet conditions.

Mechanical Resuspension: Compared with deposits in the primary system, deposits in containment will

have significantly lower particle loadings, and be distributed over larger areas. Resuspension of such

deposits is possible as a consequence of a breach of containment and/or a hydrogen burn. It is

recommended that experimental studies be performed on resuspension of real or simulated deposits at

containment-typical loadings, particularly during flow disturbances, as a function of the deposit

composition and history (dry, wet, wet then dried in situ etc.) and as the result of hydrogen deflagrations.

In addition, probabilistic studies should be undertaken to evaluate the safety significance of containment

resuspension.

NEA/CSNI/R(2009)5

10

Re-entrainment in the Containment: Re-entrainment of particulate fission products will occur at several

water and core melt pools during a severe accident. The release rates of radiological materials are relatively

small but the sources are persistent. A significant contribution to the source term by re-entrainment is

possible in the late accident phase. However, reliable analytical investigations including risk relevant

aspects do not exist yet. With a few exceptions, there are only a few codes able to simulate the FP release

from boiling or flashing sumps.

Up to now all re-entrainment tests including ThAI have been made on ideal systems with appropriate

concentrations of soluble and insoluble materials but without surfactants or impurities. Additional

experiments are required to evaluate entrainment under realistic conditions. After improvement and

validation of re-entrainment models for realistic conditions is achieved reliable accident calculations to

quantify the effect of re-entrainment from boiling pools on the source term will be possible. In the light of

these results it may be desirable to investigate measures reducing the release of fission products by

re-entrainment.

Pool scrubbing: Some BWR and PWR severe accident scenarios involve transport of radioactive aerosols

through pools of water where particles can be retained. This phenomenon, known as pool scrubbing, has

the potential to reduce the source term. Results provided by both stand-alone and integral code models

indicate satisfactory agreement with simple experiments for integral retention. However, a systematic

experimental database is required for validation purposes. Particular attention should be given to removal

of aerosols during formation and subsequent disintegration and coalescence of bubbles, and the effects of

submerged structures and contaminants (surfactants).

Removal by sprays: This issue has been extensively investigated by the French organisations CEA and

IRSN using specific apparatuses and the CARAIDAS, MISTRA and TOSQAN test facilities. The data

should be made accessible to the nuclear community, at least the OECD partners. Validated modelling

based on these experimental investigations has been implemented in the codes ASTEC and TONUS. The

ASTEC model can be found in the open literature. Further work on containment sprays is low priority for

countries that have access to this data but in other countries and for certain advanced designs it remains

important to establish effective removal by spray systems and both experimental and analytical efforts

continue.

Influence of recombiners: Phenomenological experiments have demonstrated that there is a potential for

the operation of Passive Autocatalytic Recombiners (PARs) to generate volatile molecular iodine by

thermal decomposition of metal-iodide containment aerosols. Scoping calculations indicate that this

conversion process might be a significant contribution to the molecular iodine in the containment

atmosphere. It has also to be recognised that iodine may not be the only fission product concerned, e.g.,

some formation of the highly volatile species ruthenium tetroxide might be possible in the conditions

expected within PARs though no investigation of this has been performed. Further experimental

investigations in realistic conditions (mixed-aerosol and mixed-atmosphere composition) are necessary.

Hydrogen-burn effects on suspended aerosols: Heat release by hydrogen burns may have a strong effect

on aerosol characteristics and could possibly liberate volatile forms of iodine. Experiments in the ThAI

facility demonstrate that there is a clear effect of hydrogen-combustion-induced flows on resuspension of

already deposited CsI aerosol. These findings have to be expanded to consider other types of relevant

aerosol species and other plant applications. However, chemical effects on iodine-containing aerosols have

not been studied; information from the ongoing investigation of the impact of recombiners on aerosols may

be relevant.

Release from MCCI pool: The behaviour of aerosols formed after the release from a molten corium

concrete pool was investigated in the 1990s in the ACE phase C and BETA tests and more recently in the

NEA/CSNI/R(2009)5

11

OECD-MCCI and EC Framework Programmes (LPP and MP projects). However, efforts to further aerosol

code development and validation from these experiments has been limited. As there is currently little

known activity in this area it is recommended that the following steps be initiated in the near future:

a)

● Recalculation of the old test results to evaluate the thermodynamic basis of the present models by

comparing concrete erosion processes and aerosol nucleation due to vaporization from the free

upper surface and into gas bubbles in the corium concrete pool,

● Obtain information on the characterization of concrete-based aerosols; conventional

(non-nuclear) knowledge about concrete aerosols may be a good starting point;

● Evaluate information from the EC projects MP and LPP from the specific view of fission

products release due to MCCI;

Penetration of aerosols through leak paths: From a review of available data and models including recent

research in SARNET on dry aerosol transport in cracks, the recommendation can be made that additional

separate effects and integral tests are required:

● Separate effect tests should provide a detailed characterization of the scenarios and the

phenomena necessary for model development and validation of individual depletion mechanisms;

● Integral tests should focus on measuring overall process variables such as mass retained to

provide a data base for checking the overall model performance.

The boundary conditions (hydraulic diameter, curvature of the path, fluid composition pressure drop, wall

temperature, and aerosol size) for these experiments should, obviously, be as close as possible to those

postulated under accident conditions.

For wet aerosols, it is recommended that additional experiments be performed to characterise aerosol

transport through sequential expansion and contraction regions representative of the leak path from

containment to the outside atmosphere and to evaluate the extent of leak-path plugging.

Fire aerosols: Little is known about the properties or amounts of aerosols produced from fires, and how

mixing of flaky fire aerosol with nuclear aerosol particles would impact on the aerosol depletion rate in

containment. There is a need for further experimental investigation of fire aerosols especially from cable

fires. This could be done in a future step of the OECD PRISME and/or the Sandia CAROLFIRE projects.

The aerosol production rate, the particle size distribution and the shape factors are of main concern. It is

recommended that existing multi-component aerosol models be extended in order to simulate the

interaction of fire aerosols with a pre-existing nuclear aerosol.

NEA/CSNI/R(2009)5

12

NEA/CSNI/R(2009)5

13

TABLE OF CONTENTS

EXECUTIVE SUMMARY ............................................................................................................................ 5

TABLE OF CONTENTS .............................................................................................................................. 13

1. INTRODUCTION ................................................................................................................................. 19

2. GENERAL PHENOMENA................................................................................................................... 21

2.1 Aerosol Physics in Reactor Accident Analyses .............................................................................. 21

2.2 Aerosol Formation .......................................................................................................................... 23

2.3 Growth of Aerosol Particles ........................................................................................................... 25

2.3.1 Growth by coagulation ............................................................................................................. 25

2.3.2 Growth by condensation ........................................................................................................... 28

2.4 Aerosol Growth as a Result of Hygroscopicity .............................................................................. 30

2.5 Fractal Nature of Aerosols.............................................................................................................. 31

2.6 Aerosol Deposition ......................................................................................................................... 31

2.6.1 Gravitational settling and diffusion .......................................................................................... 32

2.6.2 Inertial deposition of aerosol particles ..................................................................................... 33

2.6.3 Phoretic deposition processes ................................................................................................... 35

2.7 Resuspension of Deposited Particles .............................................................................................. 36

2.8 Aerosol Removal by Engineered Safety Systems .......................................................................... 37

2.8.1 Steam suppression pools .......................................................................................................... 40

2.8.2 Fan coolers ............................................................................................................................... 41

2.9 Aerosol Removal by Filtered Vents ............................................................................................... 41

2.10 Computer Modelling of Aerosols ................................................................................................... 43

2.11 Annotated Bibliography ................................................................................................................. 43

3. ACCIDENT PHENOMENOLOGY ...................................................................................................... 49

3.1 Formation and Growth ................................................................................................................... 49

3.1.1 Phenomena considered and state of knowledge ....................................................................... 49

3.1.2 Particle formation in the primary system ................................................................................. 52

3.1.3 Containment aerosols ............................................................................................................... 55

3.2 Impact of Thermal Hydraulics........................................................................................................ 57

3.2.1 Impact of thermal hydraulics on aerosol behaviour in the primary circuit .............................. 57

3.2.2 Impact of thermal hydraulics on aerosol behaviour in the containment................................... 59

3.3 Fission-Product Transport and Deposition ..................................................................................... 64

3.3.1 Introduction .............................................................................................................................. 64

3.3.2 Synopsis of RCS phenomena and their modelling ................................................................... 64

3.3.3 Agglomeration of aerosols ....................................................................................................... 66

3.3.4 Deposition of aerosols .............................................................................................................. 67

3.3.5 Containment ............................................................................................................................. 70

3.4 Aerosol Behaviour in Complex Structures of Steam Generator Secondary Site ............................ 73

3.4.1 Issue and status ......................................................................................................................... 73

3.4.2 Theoretical background on possible aerosol removal in the steam generator .......................... 76

3.4.3 Inertial impaction and interception in the separator and dryer sections ................................... 79

3.4.4 Other processes ........................................................................................................................ 79

NEA/CSNI/R(2009)5

14

3.5 Resuspension .................................................................................................................................. 82

3.5.1 Resuspension in primary circuit ............................................................................................... 82

3.5.2 Resuspension in containment ................................................................................................... 85

3.6 Pool Scrubbing ............................................................................................................................... 87

3.7 Re-Entrainment .............................................................................................................................. 92

3.8 Aerosol Formation during High Pressure Melt Expulsion from the Reactor Coolant System ....... 96

3.9 Aerosols from MCCI .................................................................................................................... 100

3.10 Aerosols from Fire ........................................................................................................................ 108

3.11 Spray Systems .............................................................................................................................. 111

3.12 The Impact of Catalytic Hydrogen Recombiners ......................................................................... 121

3.13 Filters ............................................................................................................................................ 123

3.14 Two Phase Flashing Jets and Water Aerosol Behaviour .............................................................. 127

3.15 Penetration Leakages .................................................................................................................... 130

3.15.1 Introduction ............................................................................................................................ 130

3.15.2 Current modelling and experimental studies .......................................................................... 131

3.15.3 Measurement of the retention of wet aerosols ........................................................................ 132

4. MODELLING APPROACHES IN CODES (INCLUDING BASIC VALIDATION) ....................... 137

4.1 Integral Codes ............................................................................................................................... 137

4.1.1 MELCOR ............................................................................................................................... 137

4.1.2 ASTEC (SOPHAEROS and CPA) ......................................................................................... 142

4.1.3 MAAP4 .................................................................................................................................. 147

4.1.4 THALES 2.............................................................................................................................. 149

4.1.5 ECART ................................................................................................................................... 155

4.1.6 APROS SA ............................................................................................................................. 157

4.2 Circuit ........................................................................................................................................... 161

4.2.1 VICTORIA ............................................................................................................................. 161

4.2.2 ATHLET-CD ......................................................................................................................... 168

4.3 Containment ................................................................................................................................. 169

4.31 CONTAIN .............................................................................................................................. 169

4.3.2 COCOSYS ............................................................................................................................. 175

4.3.3 ART/REMOVAL ................................................................................................................... 181

4.3.4 SMART .................................................................................................................................. 183

4.3.5 GOTHIC ................................................................................................................................. 184

4.3.6 KUPOL .................................................................................................................................. 185

5. RECENT VALIDATION WORK ....................................................................................................... 187

5.1 Integral Experiments .................................................................................................................... 187

5.1.1 The PHÉBUS fission product programme ............................................................................. 187

5.1.2 ISP-46 (PHÉBUS FPT1) ........................................................................................................ 190

5.2 Circuit ........................................................................................................................................... 193

5.2.1 Revaporization in the FPT0, FPT1 and FPT2 circuits ........................................................... 193

5.2.2 FALCON (Including ISP-34) ................................................................................................. 194

5.2.3 STORM (Including ISP-40) ................................................................................................... 197

5.2.4 WIND ..................................................................................................................................... 204

5.3 Containment Experiments ............................................................................................................ 207

5.3.1 DEMONA .............................................................................................................................. 207

5.3.2 MARVIKEN-V ...................................................................................................................... 209

5.3.3 LACE ..................................................................................................................................... 211

5.3.5 VANAM (including ISP-37) .................................................................................................. 217

5.3.6 KAEVER (including ISP-44) ................................................................................................. 222

NEA/CSNI/R(2009)5

15

5.3.7 AHMED ................................................................................................................................. 228

5.3.8 VICTORIA ............................................................................................................................. 232

5.4 Aerosol Release in the Course of MCCI (ACE-C) ....................................................................... 236

5.5 REST, REVENT, ThAI Re-Entrainment Tests ............................................................................ 237

5.6 Pool Scrubbing Tests .................................................................................................................... 239

5.7 Resuspension Tests ....................................................................................................................... 242

5.7.1 Continuous flow experiments ................................................................................................. 242

5.7.2 Transient flow experiments .................................................................................................... 243

5.8 Spray Systems (French Tests) ...................................................................................................... 244

5.9 Containment Venting Filters ........................................................................................................ 247

5.9.1 International efforts for qualification of containment venting rilters ..................................... 248

5.9.2 CCI containment venting filter ............................................................................................... 255

5.9.3 Removal of iodine by the containment venting filters ........................................................... 258

5.9.4 International status of use of containment venting filters ...................................................... 258

5.10 Ongoing Tests ............................................................................................................................... 258

5.10.1 Aerosol behaviour in steam generators .................................................................................. 258

5.10.2 EVAN ..................................................................................................................................... 264

5.10.3 Penetration leakage tests ........................................................................................................ 265

5.10.4 ThAI aerosol tests ................................................................................................................... 266

5.10.5 Impact of catalytic hydrogen recombiners ............................................................................. 269

5.10.6 Aerosol growth under saturated conditions (Canadian tests) ................................................. 272

6. EXAMPLES FOR VALIDATION ...................................................................................................... 273

6.1 Comparison of MELCOR Predictions to Experiments ................................................................ 273

6.2 CONTAIN for PHÉBUS FPT1 .................................................................................................... 277

6.3 Example for Uncertainty and Sensitivity Analyses of Two Aerosol Calculations ....................... 283

7. SOURCE TERM CALCULATIONS IN PLANT APPLICATIONS ................................................. 287

7.1 MELCOR Calculation for a US American PWR (Station Blackout Scenario) ............................ 287

7.2 ASTEC Calculation for a German PWR (MB LOCA Scenario) ................................................. 294

7.3 Aerosol-Related Uncertainties in the Prediction of Severe Accident Source Terms ................... 304

8. IDENTIFIED OPEN ISSUES (INCLUDING RECOMMENDATIONS) .......................................... 307

8.1 Introductory Remarks ................................................................................................................... 307

8.2 Generic Issues ............................................................................................................................... 308

8.2.1 Code-users’ workshop on plant analysis ................................................................................ 308

8.2.2 Shape factors .......................................................................................................................... 308

8.2.3 Computational fluid dynamics codes ..................................................................................... 309

8.3 Reactor Coolant System Issues .................................................................................................... 309

8.3.1 Mechanical resuspension ........................................................................................................ 309

8.3.2 Deposition in singularities and complex structures ................................................................ 310

8.3.3 Particle break-up in highly turbulent flows ............................................................................ 311

8.3.4 Influence of chemistry ............................................................................................................ 311

8.3.5 Revaporisation of deposits ..................................................................................................... 312

8.4 Containment Issues ....................................................................................................................... 313

8.4.1 Charge effects ......................................................................................................................... 313

8.4.2 Mixed aerosols in condensing atmospheric conditions .......................................................... 313

8.4.3 Mechanical resuspension ........................................................................................................ 313

8.4.4 Re-entrainment from pools ..................................................................................................... 314

8.4.5 Pool scrubbing ........................................................................................................................ 314

8.4.6 Removal by sprays ................................................................................................................. 315

NEA/CSNI/R(2009)5

16

8.4.7 Influence of recombiners ........................................................................................................ 315

8.4.8 Hydrogen-burn effects on suspended aerosols ....................................................................... 315

8.4.9 Release from MCCI pool ....................................................................................................... 316

8.4.10 Penetration through leak paths ............................................................................................... 317

8.4.11 Fire aerosols ........................................................................................................................... 317

8.5 Concluding Remarks .................................................................................................................... 318

9. APPENDIX 1: Characteristics of Aerosols under LWR Severe Accident Conditions ................... 323

9.1 Context ......................................................................................................................................... 323

9.2 Review of Available Information ................................................................................................. 323

9.2.1 Aerosols in the RCS ............................................................................................................... 324

9.2.2 Aerosols in the containment ................................................................................................... 329

9.3 Discussion .................................................................................................................................... 331

9.3.1 Uranium contribution ............................................................................................................. 331

9.3.2 Tin contribution ...................................................................................................................... 331

9.3.3 Silver contribution .................................................................................................................. 331

9.3.4 Cadmium contribution ............................................................................................................ 331

9.3.5 Indium contribution ................................................................................................................ 331

9.3.6 Fission product contribution ................................................................................................... 332

9.3.7 Size, shape and structure ........................................................................................................ 332

9.3.8 Variability............................................................................................................................... 333

9.3.9 Other considerations ............................................................................................................... 333

9.4 Conclusion .................................................................................................................................... 334

10. APPENDIX 2: Aerosol Shape Factors ............................................................................................. 337

10.1 Fundamentals ................................................................................................................................ 337

10.2 Dynamic and Collision Shape Factors ......................................................................................... 338

11. APPENDIX 3: Spray Modelling Developed from Recent Analytical Work ................................... 345

11.1 Relaxation of Droplets .................................................................................................................. 345

11.2 Droplet Coalescence ..................................................................................................................... 346

11.3 Coupling of Droplet Relaxation and Coalescence ........................................................................ 347

11.4 Evolution of the Atmosphere Conditions ..................................................................................... 349

11.5 Aerosol Removal Modelling ........................................................................................................ 350

11.5.1 Inertial capture ........................................................................................................................ 350

11.5.2 Interception............................................................................................................................. 351

11.5.3 Brownian diffusion ................................................................................................................. 352

11.5.4 Phoretic capture ...................................................................................................................... 352

11.6 Gaseous Iodine Removal by Sprays ............................................................................................. 353

12. APPENDIX 4: Overview of Filtration Devices ............................................................................... 357

12.1 Nuclear Aerosol Filtration ............................................................................................................ 357

12.1.1 Development of the high-efficiency particulate air (HEPA) filter ......................................... 357

12.1.2 Challenges for test procedures ............................................................................................... 359

12.1.3 Demonstrated safety by the use of HEPA filters .................................................................... 359

12.1.4 Deep-bed sand and glass fibre filters ..................................................................................... 359

12.1.5 Brief history of gas adsorption ............................................................................................... 360

12.2 Type of Filters in Use ................................................................................................................... 361

12.3 Normal Operation and Design Basis Accidents ........................................................................... 361

12.4 Brief Review on Mechanisms of Filtration .................................................................................. 363

12.5 Characterisation of Filter Performance......................................................................................... 365

NEA/CSNI/R(2009)5

17

12.6 Cut Diameter Method .................................................................................................................. 367

12.7 Fibrous Filter ............................................................................................................................... 368

12.8 Granular Beds .............................................................................................................................. 370

12.9 Sand Beds .................................................................................................................................... 373

12.10 Gravel Beds ................................................................................................................................. 374

12.11 Venturi Scrubbers ........................................................................................................................ 376

12.12 Water Pools ................................................................................................................................. 379

13. APPENDIX 5: Point-by-Point Review of Issues Identified at the 1998 Aerosol Workshop ........... 385

NEA/CSNI/R(2009)5

18

NEA/CSNI/R(2009)5

19

1. INTRODUCTION

The prediction of nuclear aerosols behaviour associated with postulated accidents in nuclear power plants

is necessary for the assessment of the radiological consequences of these accidents and hence is an

important aspect of reactor safety evaluation. The nature and behaviour of nuclear aerosols can potentially

influence both the course and the consequences of reactor accidents. For example, nuclear aerosols can

affect the performance of engineered safety systems (e. g. air cleaning systems) as well as the magnitude,

dispersion and effects of the radioactive source term leaked to the atmosphere. As a result of the extreme

conditions for nuclear aerosols in case of an accident, they exhibit very dynamic mostly physical, but also

chemical behaviour and pose special analytical and experimental problems different from those associated

with aerosols found under industrial and ambient conditions.

Following a LWR severe accident, the overall radionuclide retention in form of aerosol, both in reactor

coolant system and containment, is the result of three processes: transport, deposition and release from dry

or wet surfaces (resuspension) or (boiling) water pools (re-entrainment).

Approximately a 30 years tradition in the preparation of state-of-the-art reports on nuclear aerosols and the

proceedings of workshops concerning the aerosol issue (summarised in chronological order at the end of

this chapter [1 - 8]) demonstrate the substantial work performed by the nuclear community and the

progress made in this period of 30 years.

Nevertheless at the last workshop in Cologne, 1998, some important issues were identified, where

knowledge did not seem to be sufficient for realible predictions. Following the recommendations of this

workshop the CSNI decided to prepare a state-of-the-art report with three main objectives:

• to summarise the present experimental and analytical knowledge on nuclear aerosols

• to give some examples for validation results and in particular for plant applications, both including

uncertainties

• to identify safety relevant still unresolved issues

Nevertheless, it should be understood that the subject matter of the report is nuclear aerosols, and the report

does not purport to cover the whole field of radioactive source terms for severe LWR accidents. For

example, there is no detailed discussion of fission product chemistry processes that do not have a direct

bearing on aerosol behaviour, such as iodine solution chemistry and organic iodine production.

Finally the authors of this report wish to acknowledge significant contributions from a large number of

colleagues, which have increased the quality of the report considerably.

References

[1] NEA Group of Experts, Nuclear Aerosols in Reactor Safety , A state-of-the-art report by a group

of experts of the NEA committee on the safety of nuclear installations, June 1979

[2] CSNI Specialist Meeting on Nuclear Aerosols in Reactor Safety in Gatlinburg, April 1980

NEA/CSNI/R(2009)5

20

[3] CSNI Group of Experts on Nuclear Aerosols in Reactor Safety, March 1983

[4] CSNI Specialist Meeting on Nuclear Aerosols in Reactor Safety Workshop Karlsruhe, September 1984

[5] NEA Group of Experts, Nuclear Aerosols in Reactor Safety - Supplementary Report

NEA / OCDE /OECD, Paris 1985

[6] Nuclear Engineering Applications Section Species to Aerosols - Workshop on Water-Cooled

Reactor Aerosol Code Evaluation and Uncertainty Assessment, Brussels, September 1987

[7a] OECD / NEA, Aerosol behaviour and thermal-hydraulics in the containment (2

nd

workshop

Brussels 1987, Technical Summary), NEA/CSNI/R(92)1, Fontenay-aux-Roses, 1990

[7b] OECD / NEA Aerosol behaviour and thermal-hydraulics in the containment (2

nd

workshop

Brussels 1987, Proceedings) NEA/CSNI/R(92)1, Fontenay-aux-Roses, 1990

[8] Third OECD Specialist Meeting on Nuclear Aerosols in Reactor Safety GRS-166,

NEA/CSNI/R(98)4, ISBN 3-931995-31-3, Cologne, June 1998

NEA/CSNI/R(2009)5

21

2. GENERAL PHENOMENA

This chapter provides background and introductory information and is directed primarily at those readers

with an interest in being reminded of the fundamentals of aerosol behaviour under severe reactor accident

conditions. In addition, there is an annotated bibliography that will introduce the reader to the pertinent

research literature.

2.1 Aerosol Physics in Reactor Accident Analyses

Most of the radioactive material that can escape from a nuclear power plant during a severe reactor

accident will do so in the form of aerosols. Much of reactor accident analysis is the prediction of the

behaviour of these radioactive aerosols. Aerosols are very small solid particles or liquid droplets suspended

in a gas phase. The suspended solid or liquid particles typically have a range of sizes. Particles may range

in size from 0.01 µm to 20 µm. Aerosol concentrations in reactor accident analyses are typically less than

100 g/m

3

and usually less than 1 g/m

3

. At these concentrations, the aerosol particles little affect the gas

hydrodynamics, but the gas dynamics profoundly affect the behaviour of the suspended particles. The

behaviours of the larger aerosol particles are described usually by continuum mechanics. The smallest

particles have diameters less than the mean free path of gas phase molecules and the behaviour of these

particles can often be described well by free molecular physics. The vast majority of aerosol particles

arising in reactor accident analyses have behaviours in the very complicated regime intermediate between

the continuum mechanics and free molecular limit. In this regime, aerosol behaviour must be described

using some approximate solution of the Boltzmann equation.

The mechanical regimes of aerosol behaviour are usually categorised in terms of the Knudsen number, Kn,

which is the ratio of the mean free path of

gas molecules, λ, to the particle diameter

p

D :

Continuum behaviour is approached for Kn < 0.1 and free molecular flow is approached for Kn > 10.

These regimes vary with temperature and pressure which affect the mean free path. At atmospheric

pressure and room temperature the mean free path of air is about 0.06 µm.

The number density of aerosol particles in a gas phase can be huge - exceeding 10

13

/m

3

. It is quite

impossible to predict aerosol behaviour by calculating the dynamics of individual particles. Instead

aerosols must be considered in a collective sense and the aerosol is taken to have some continuous

distribution of particle sizes. Given sufficient time in a quasi-steady state environment with no continued

injection of aerosol into the gas phase, an aerosol subjected to particle growth by agglomeration and

gravitational deposition onto surfaces will develop a size distribution that is approximated well by a

log-normal distribution. The probability density for particles having sizes in the interval

p

D to

p

D + d

p

D

is:

p

D

2

Kn

λ

=

NEA/CSNI/R(2009)5

22

p

2

p

p

Dn1d

σn21

µ/nD1

exp

σn12

1

)D(pdf

−

π

=

where:

µ = mean particle size

σ = geometric standard deviation of the size distribution

It is common to report aerosol size data in terms of the parameters of the lognormal size distribution (µ and

σ) whether or not the aerosol satisfies the criteria for the lognormal distribution being a good

approximation of the actual size distribution. Example size distribution for the case of a very narrow size

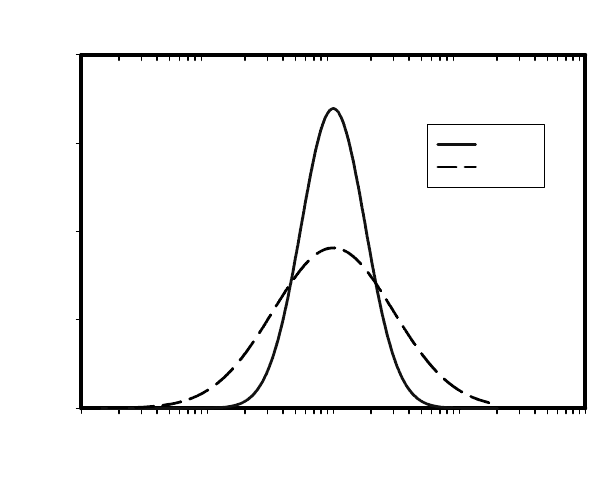

distribution (σ = 1.8) and for the case of a broad distribution (σ = 3) are shown in Fig. 2.1-1.

When there are continuing sources of aerosol to the gas phase or when there are complicated processes

involving engineered safety features much more complicated size distributions develop. It is not

uncommon for aerosols in reactor containments to have bimodal size distributions at least for some

significant periods of time early in an accident.

Salient features of aerosol physics under reactor accident conditions that will affect the nature of the

aerosols are:

• formation of aerosol particles

• growth of aerosol particles

• shape of aerosol particles

• deposition of particles on surfaces

• resuspension of aerosol particles

Introductory or background information on these and other aspects of nuclear aerosols are provided in the

subsections of this chapter that follow. This chapter is concluded with a brief description of the numerical

methods used to model the important aerosol phenomena.

NEA/CSNI/R(2009)5

23

Particle Size (µm)

0.01 0.1 1 10 100

Probability Density

0.0

0.2

0.4

0.6

0.8

σ = 1.8

σ = 3.0

Fig. 2.1-1 Comparison of log normal distributions with different geometric standard deviations, s, and

the same mean, µ

2.2 Aerosol Formation

Aerosol particles can be formed by the mechanical comminution of materials or by the condensation of

vapors. Mechanical processes that produce aerosol particles in reactor accidents include:

• entrainment of solids or liquid droplets in high velocity gas flows,

• expulsion of droplets by gases bubbling through liquids,

• shock waves such as those produced in energetic interactions of molten materials with coolants, and

• high pressure melt ejection from the reactor coolant system.

Mechanical processes seldom produce very fine particles that can remain suspended in the gas phase for

protracted periods of time. Typically, mechanical processes will not produce particles smaller than about

1-2 µm. Furthermore, most mechanical processes that can produce aerosols are not of prolonged duration

and are, thus, not enduring sources of aerosols through large periods of an accident. An exception is the

production of aerosols by the bursting of bubbles of gas sparging through liquids. But, the bubble burst

source is not an especially intense source of aerosol particles. Aerosol production by mechanical processes

is largely ignored in most reactor accident analyses.

Nucleation of particles from supersaturated vapors is the more important source of aerosols in reactor

accidents and certainly the source given the most attention in reactor accident analysis computer codes.

Vapors rich in radioactive materials are formed from high temperature core debris materials. The vapors

become supersaturated as they are transported from the vicinity of the core debris to cooler regions. These

supersaturated vapors can nucleate aerosol particles.

Vapor nucleation is a very complicated physical process even when the vapor consists of a single

condensable species. Nucleation can occur homogeneously from the vapor when the supersaturation ratio

NEA/CSNI/R(2009)5

24

(ratio of the actual partial pressure of condensable species divided by the equilibrium partial pressure of

that species) exceeds a value of 4 - 10. Nucleation is a kinetic process and there is not a sharp onset to this

process. Nucleation is usually taken to be occurring when the rate of particle production exceeds one

particle per cubic centimeter per second. The supersaturation necessary for any particular vapor to nucleate

is a sensitive function of the surface energy of the condensed phase (surface tension in the case of a liquid

being produced from the vapor). The rate of tin vapor nucleation is shown in Fig. 2.2-1 as a function of

temperature for a vapor initially saturated at 1800 K. It can be seen from this example that nucleation

occurs whenever the gas is saturated, but nucleation is quite slow until a substantial supersaturation

develops. That is, the vapor has to cool well below saturation for detectable nucleation to be observed.

Detectable nucleation (Rate > 1 particle/cm

3

-s) of the tin aerosol occurs rather abruptly over a narrow

temperature range at a temperature over 100 K lower than the temperature at which the vapor becomes

saturated. The enormous nucleation rates predicted at still lower temperatures are difficult to realise in

practice because heat liberated by nucleation cannot be dissipated from the system.

Temperature (K)

1600 1620 1640 1660 1680 1700 1720

Nucleation Rate (particle/cm

3

-s)

Nucleation Rate

1 particle/cm

3

-s

Fig. 2.2-1 Nucleation kinetics of tin vapor initially saturated at 1800 K

Heterogeneous nucleation of vapor on ions in the gas phase can occur at supersaturations that are lower

than those needed to drive homogeneous nucleation. The gas phase in a nuclear reactor accident will be

intensely irradiated so there will be relatively high concentrations of ions to act as sites for nucleation.

Some heterogeneous nucleation of vapors will occur. But, supersaturation ratios that will develop when

high temperature vapors escape the regions of core debris into cooler regions can exceed 10

4

. Since

nucleation is kinetic in nature, it is quite likely that both homogeneous nucleation and heterogeneous

nucleation will occur simultaneously.

The theory of nucleation of complex vapors produced in reactor accidents is vastly more complicated than

the theory for single pure vapors outlined above. Indeed, a general theory of nucleation for complex vapors

has not yet been developed. The qualitative features of nucleation from complex vapor mixtures are

expected to be similar to those of pure vapor nucleation although quantitative features may differ and

calculation of these features will involve vapor and condensed phase properties that are not readily

NEA/CSNI/R(2009)5

25

available. Consequently, when nucleation phenomena are considered in accident analyses, approximate

models based on nucleation of single vapors are used. The upper and lower bound models of Reiss, Katz

and Cohen are quite popular.

It is more common especially in the so-called “lumped node” computer models of reactor accidents to omit

mechanistic modeling of nucleation processes. Particle formation is simply assumed to occur when the

vapor reaches saturation. The omission is justified by the rapid development of supersaturation in the gas

flowing into ever cooler environments and the rapid growth of particles that are nucleated from the vapor.

This sudden growth of the nucleated particles can obscure any effects of the details of nucleation kinetics

at the “lumped node” level of approximation. Recently, mechanistic treatments of vapor nucleation have

been included in computational fluid dynamics models of flows during reactor accidents. In some cases,

these models are showing unexpected complexity in the aerosol deposition because of the spatial variations

in the supersaturation along a flow path. These findings are, of course, subjects of continued research.

2.3 Growth of Aerosol Particles

2.3.1 Growth by coagulation

Aerosol particles grow by continued condensation of vapor on the nucleated particles and by the

coagulation of these particles. Vapor condensation on nucleated particles is limited by the rate at which

heat liberated by condensation can be removed. Interior to a cloud of nucleating vapor, only conduction

can remove this heat. Velocity differences between the gas phase and the particles are too small to promote

much convective heat transport and optical paths for radiation heat transfer are effective only near the

perimeter of the cloud. Though some continued vapor condensation will occur, coagulation is the dominant

mechanism of particle growth following nucleation. Coagulation greatly affects the size and consequently

the mobility of aerosol particles, so the aerosol particles quickly develop a size distribution. The evolution

of this size distribution is described by the intergrodifferential equation:

du)uv(n)uv,u(K

v

0

2

1

t

)v(n

−−

∫

=

∂

∂

du)u(n)v,u(K

0

)v(n

∫

∞

−

)v(S)v(n)v(R +−

where:

n (v) = number density of particles of volume v to v + dv (particles/cm

3

)

K (u,v) = collision kernal for particles of volume v and volume u (s

-1

)

R (v) = rate constant for deposition of particles of volume v on surfaces (s

-1

)

S (v) = source rate of particles (particles/cm

3

-s)

The first integral on the right-hand side of this equation is the coagulation of particles of volume u and v- u

to form a particle of volume, v. The second integral is the coagulation of particles of volume v with

particles of any volume to form a particle that is no longer in the v to v + dv volume interval.

Particles coagulate because they cross stream lines of flow to come into contact. There are a variety of

mechanisms that can cause particles to cross stream lines. Each of these mechanisms is characterised by a

distinct collision kernel, K(u,v). The more common collision kernels recognised in models of aerosol

growth during reactor accidents are:

NEA/CSNI/R(2009)5

26

• Gravitational - larger particles sweep out smaller particles as they fall under the force of gravity

()

()

() ()

|uuCvvC|uvv,u

g

4

3

9

2

v)(u, K

3/23/2

2

3/13/1

0

g

p

2

3/4

g

−+∈

µ

Ρ

χ

γ

π

π

=

where:

γ

= collision shape factor

χ = dynamic shape factor

g = gravitational acceleration

p

ρ = material density of the particle

g

µ = gas viscosity

()

2

3/13/1

3/2

0

vu

v

+

β

=∈

β = 0.5 or 1.5

C(v) = Cunningham slip correction factor for a particle of volume v

• Brownian diffusion - fluctuations in molecular bombardment drive particles across streamlines of

flow to contact other particles.

()

()

(

)

(

)

++

µ

=

3/13/1

3/13/1

g

B

u

uC

v

vC

uv

3

kT2

v,uK

where:

k = Boltzmann constant = 1.38066 x 10

-16

ergs/K

T = absolute temperature (K)

• Turbulent dif fusion - turbulent eddies carry particles across streamlines to contact other particles

()

()

2/1

g

gT

3

3/13/1

TD

uv

4

Z3

v,uK

µ

ρ∈

+

π

=

where:

T

∈ = turbulent energy dissipation rate

1.29 ≤ Z ≤ 5.65

• Turbulent inertia - particles expelled from turbulent eddies impact other particles

()

()( )

4/1

g

g

3

T

g

p

3/23/2

2

3/13/1

TI

|vu|uvZv,uK

µ

ρ∈

µ

ρ

−+

′

=

where:

0.188 ≤ Z

′

≤ 0.204

NEA/CSNI/R(2009)5

27

The Cunningham slip correction factor, C(v), that arises in these various expressions for the collision

kernels to account for deviations from continuum mechanics is empirically derived from data for spherical

particles. Many different expressions have been given for this correction factor. A commonly used one is:

()

(

)

(

)

Kn/999.0exp588.0142.1Kn1vC −++=

3/1

v6

2

Kn

π

λ

=

The collision kernels and the slip correction factor are shown in Fig. 2.3-1 and Fig. 2.3-2 as functions of

particle size for a particular set of circumstance (pressure, temperature, etc.).

In many circumstances, one of the mechanisms of coagulation is dominant. There are other circumstances

in reactor accident analyses in which several coagulation mechanisms act with similar magnitudes. This

gives rise to the issue of addition of kernels. Often kernels are simply added. In other cases more

complicated summations are used such as:

() () () () ()

v,uKv,uKv,uKv,uKv,uK

2

TI

2

TDgBtotal

+++=

Research in aerosol physics includes efforts to develop more defensible descriptions of the combined

effects of simultaneous coagulation mechanisms.

u

1/3

(µm)

0.001 0.01 0.1 1 10 100

Collision Kernel

1e-13

1e-12

1e-11

1e-10

1e-9

1e-8

1e-7

1e-6

1e-5

gravitational

Brownian diffusion

turbulent diffusion

turbulent inertia

Fig. 2.3-1 Example collision kernels for various mechanisms of coagulation

NEA/CSNI/R(2009)5

28

Slip Correction Factor

Knudsen Number, Kn

0.001 0.01 0.1 1 10 100

Cunningham Slip Correction Factor, C

0

10

20

30

40

50

Fig. 2.3-2 Cunningham slip correction factor as a function of Knudsen number

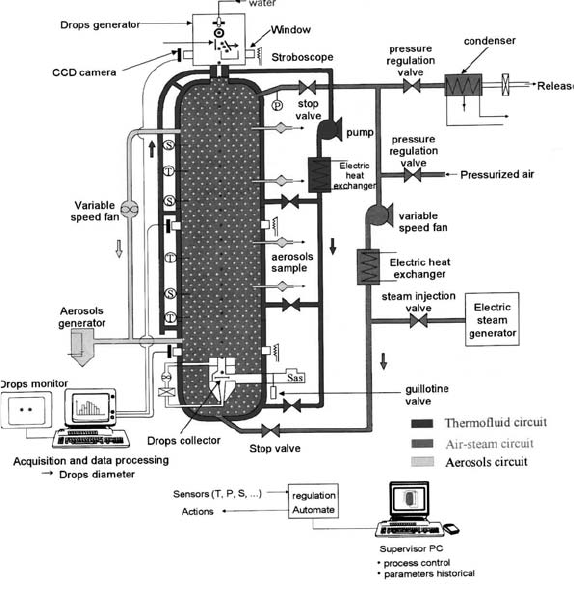

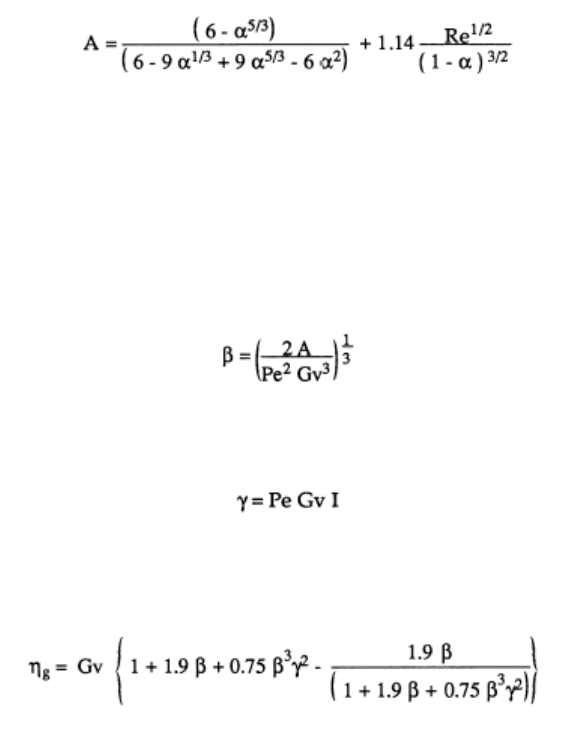

Other coagulation mechanisms can be identified, such as laminar shear. These are not often included in