AS 4775:2007

COMPLIANCE CHECKLIST

AND TECHNICAL

GUIDELINES

TO PREVENT HARM FROM HAZARDOUS SUBSTANCES, TO PEOPLE AND THE ENVIRONMENT

WWW.DALTONINTERNATIONAL.CO.NZ

www.dilnz.co.nz | Tel: 0800 323 223

2

TABLE OF CONTENTS

3 Foreword

4 Introduction

5-7 General Considerations

8 Emergency Shower Checklist

9 Eye/Face Washes Checklist

10 Safety Stations Checklist

11 Guardian Technology

12 Installation and Maintenance

13-15 Corrosive Resistance Guide

COMPLIANCE & TECHNICAL

www.dilnz.co.nz | Tel: 0800 323 223

3

FOREWORD

Businesses use products with hazardous properties (hazardous substances) on a daily basis. Goods that are ammable, corrosive,

explosive, toxic, oxidising or ecotoxic are useful because of their hazardous properties i.e. petrol that didn’t ignite wouldn’t be a

very useful fuel for vehicles.

However, because of their properties, hazardous substances can cause serious harm to people and the environment and

additional care must be taken when storing, handling and disposing of these substances.

Dalton International is dedicated to preventing harm from hazardous substances to people and the environment. We do this every

day by working towards our Vision of being New Zealand’s leading provider of safety solutions for businesses working with

hazardous substances.

www.dilnz.co.nz | Tel: 0800 323 223

4

INTRODUCTION

INTRODUCTION

The selection of emergency eyewash and shower equipment is often a complicated process. In addition to addressing design and

engineering issues, speciers must be aware of regulatory requirements and compliance standards. In Australia and New Zealand

the relevant standard is AS4775:2007 “Emergency Eyewash and Shower Equipment” which sets out requirements for the proper

selection, installation, operation and maintenance of emergency equipment. AS4775:2007 is based on the American standard

ANSI/ISEA Z358.1 and is essentially replicated with change to the units of measure and some other minor changes. E.g. the shower

minimum owrate requirement of 20 GPM (Gallons per minute) in the ANSI standard is changed to 75.7 LPM in the AS/NZS

standard.

To assist speciers and end users in understanding the provisions of the AS4775:2007 standard, Dalton International Ltd has

prepared this Compliance Checklist. In this Checklist, we have summarised and graphically presented the provisions of the standard.

This Checklist can serve as a starting point for designing and planning emergency eyewash and shower systems and also highlights

the maintenance requirements to ensure your chosen equipment continues to function properly.

LEGAL REQUIREMENTS

The Health and Safety at Work Act 2015 (HSWA) is New Zealand’s workplace health and safety law. It introduced new responsibilities

for managing the work-related risks that could cause serious injury, illness or even death.

In workplaces where there is a risk of chemical spills, splashes or accidents the PCBU (Person In Charge of Business or Undertaking)

is required to take all practicable steps to ensure that risks are identied, and either eliminated, isolated or as a last resort mitigated.

Providing emergency showers and eyewashes that comply with AS4775:2007 is part of the solution to mitigate the risk of chemical

splashes.

AS4775:2007 & ANSI Z358.1

AS4775:2007 is based on the American standard ANSI Z358.1 but is not identical. Some minor changes have been made to address

the specic needs of Australian applications, and integrate with other Australian Standards. The main dierences are as follows:

Inclusion of guidance on dimensional constraints for disabled access.

Inclusion of guidance on local materials for plumbing components.

Inclusion of guidance on good design and manufacture.

AS4775:2007 covers the following types of equipment:

Emergency shower equipment.

Eyewash equipment.

Eye/face wash equipment.

Combination shower and eyewash or eye/face wash equipment.

Facilities for disabled persons.

Supplemental equipment including drench hoses and self-contained equipment

The objective of this Standard is to provide uniform minimum requirements for equipment performance, installation, use,

maintenance and training of users, along with relevant test procedures.

This Compliance Checklist summarises the key parts of the standards. It is not intended as a replacement for reading the standards

and we strongly recommend that a copy of the standard be purchased and understood before purchasing any emergency shower

or eyewash equipment.

www.dilnz.co.nz | Tel: 0800 323 223

5

GENERAL CONSIDERATIONS

01

FIRST AID DEVICES

Emergency eyewash and shower units are designed to deliver water to rinse contaminants from a user’s

eyes, face or body. As such, they are a form of rst aid equipment to be used in the event of an accident.

However, they are not a substitute for primary protective devices (including eye and face protection and

protective clothing) or for safe procedures for handling hazardous materials.

02

LOCATION OF EMERGENCY EQUIPMENT

In general, the standard provides that emergency equipment be installed within 10 seconds walking time

from the location of a hazard (approximately 16m). The equipment must be installed on the same level as the

hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel

from the hazard to the equipment should be free of obstructions and as straight as possible.

However, there are certain circumstances where these guidelines may not be adequate. Where workers are

handling particularly strong acids, caustics or other materials where the consequences of a spill would be

very serious, emergency equipment should be installed immediately adjacent to the hazard.

Laboratory environments may also require special consideration. It has been common in many laboratory

buildings to install emergency equipment in a corridor or hallway outside of the lab room. Since a door is

considered an obstruction, this violates the provisions of the standard. For laboratory environments, we

recommend installing (i) recessed laboratory eyewash/shower cabinets inside the lab room and (ii) dual

purpose eyewash/drench hose units at lab sinks. The recessed cabinet units are a space saving design

that satisfy the standard’s requirements for both a shower and an eye/face wash, and are wheelchair

accessible, while the eyewash/drench hoses provide immediate protection for the eyes, face or body when

a spill involves a relatively small amount of hazardous material.

www.dilnz.co.nz | Tel: 0800 323 223

6

GENERAL CONSIDERATIONS

05

CORROSION RESISTANCE

Once connected to a water supply line, water will enter the emergency equipment and stand in the unit

up to the valve(s). When activated, water will ow through the entire unit. Therefore, the unit must be

constructed of materials that will not corrode when exposed to water for extended periods of time. In addition

to this general provision, the standard specically requires that valves be resistant to corrosion. Emergency

equipment should therefore be constructed of materials that will resist rusting and corrosion. Materials that

are considered acceptable for this purpose include brass, galvanized steel and many types of plastics (ABS,

nylon, etc.). However, these materials may not provide durable service when exposed to harsh industrial

conditions, may deteriorate in direct sunlight or be subject to other limitations.

Therefore, for maximum durability, the following materials should also be considered:

Epoxy coated galvanized steel

Epoxy coated brass

Stainless steel

PVC

06

FREEZING

There are many applications where emergency equipment must be installed in areas that are subject to

freezing conditions. Such areas may include any type of outdoor area (bulk material handling facility, tank

farm, etc.), as well as some interior areas (loading docks, low temperature facilities, etc.). In these cases, the

emergency equipment must be protected against freezing.

Equipment that is designed and manufactured to be freeze-resistant should be installed. There are a

number of dierent types of freeze-resistant equipment, including:

Units that have a temperature actuated bleed valve that permits water to ow through the unit when

the temperature drops below freezing. These units are generally used only where the possibility of

freezing is very infrequent.

Units on which the valve is mounted behind a wall or buried below the frost line and is

remote-activated.

Combination units that are electrically heated (heat-traced) and insulated.

Units that have a heated enclosure to fully contain and protect both the equipment and the user.

03

WATER TEMPERATURE

The standard states that the water temperature delivered by emergency equipment should be ‘tepid.’

Tepid is dened to be between 16°C and 38°C. However, in circumstances where a chemical reaction is

accelerated by ushing uid temperature, a facilities safety/health advisor should be consulted to determine

the optimum water temperature for each application.

The delivery of tepid water to emergency equipment may raise complicated engineering issues. At a

minimum, it generally involves providing both hot and cold water to the unit, and then installing a mixing

valve to blend the water to the desired temperature. Guardian oers a variety of mixing valves and turnkey,

recirculating tempering systems to provide tempered water. Please contact Dalton International’s oce for

further information.

04

SHUT OFF VALVES

Plumbed emergency equipment must be connected to a potable water supply line. It may be advisable to

install a shut o valve on the water line, upstream of the unit, to facilitate maintenance of the equipment. If a

shut o valve is installed, provision must be made to prevent unauthorized closure of the shut o valve. Such

provision can include removing the handle of the shut o valve or locking the valve in the open position. Only

maintenance personnel should be authorised to place a handle on or unlock the valve.

www.dilnz.co.nz | Tel: 0800 323 223

7

GENERAL CONSIDERATIONS

07

DISPOSAL OF WATER

The standard does not include any specic provisions regarding the disposal of waste water. However,

designers must give consideration to where waste water will go. In particular, care must be taken that waste

water not create a hazard (i.e. by creating a pool in which someone might slip) or freeze.

Generally, Guardian eyewash, eye/face wash and safety station units are designed with waste connections

for connection to drain piping. WE RECOMMEND THAT EMERGENCY EYEWASH AND SHOWER UNITS

BE CONNECTED TO DRAIN PIPING. FOR EMERGENCY SHOWERS AND FOR OTHER UNITS WITHOUT

WASTE CONNECTIONS, FLOOR DRAINS SHOULD BE PROVIDED.

After an emergency eyewash or shower unit has been used, the waste water may contain hazardous

materials that cannot or should not be introduced into a sanitary sewer. It may be necessary to connect the

drain piping from the emergency equipment or oor drain to the building’s acid waste disposal system or to

a neutralising tank.

08

EMERGENCY RESPONSE

Simply installing emergency equipment is not sucient to assure worker safety. Employees must be trained

in the location of emergency equipment and in its proper use. Emergency equipment must be regularly

maintained (including weekly activation of the equipment) to assure that it is in working order and inspected

at least annually for compliance with the standard. Most importantly, employers should develop a response

plan to be used in the event that an accident does occur. The focus of the response plan should be to provide

assistance to the injured worker as quickly as possible.

Guardian oers a variety of alarm systems that may be installed in conjunction with our emergency

equipment. They serve to alert personnel and summon assistance if an eyewash or shower is activated.

WE RECOMMEND INSTALLING AN ALARM UNIT WITH ANY EMERGENCY EYEWASH OR SHOWER UNIT.

09

O&M INFORMATION

Under the standard, the manufacturer of the emergency equipment must provide detailed instructions on

the proper operation, inspection and maintenance of the emergency equipment. This information should

be accessible to maintenance personnel. Guardian oers detailed installation, operation and maintenance

guides for its equipment. These guides are available on the Dalton International’s website (dilnz.co.nz) and

from our sales representatives.

NOTE: THIS COMPLIANCE CHECKLIST IS INTENDED TO ASSIST DESIGN

PERSONNEL, FACILITY OWNERS AND OTHERS IN SELECTING, SPECIFYING,

INSTALLING AND MAINTAINING EMERGENCY EQUIPMENT. WE HAVE TRIED TO

ASSURE THAT IT IS COMPREHENSIVE AND ACCURATE. HOWEVER, PLEASE REFER

TO THE COMPLETE AS 4775:2007 STANDARD BEFORE PURCHASING OR

INSTALLING EMERGENCY EQUIPMENT. GUARDIAN EQUIPMENT CANNOT BE

RESPONSIBLE FOR ANY ERRORS OR OMISSIONS FROM THIS CHECKLIST, AND

CANNOT ASSURE THAT ANY PARTICULAR PRODUCT WILL PERFORM

SATISFACTORILY IN ANY PARTICULAR APPLICATION.

www.dilnz.co.nz | Tel: 0800 323 223

8

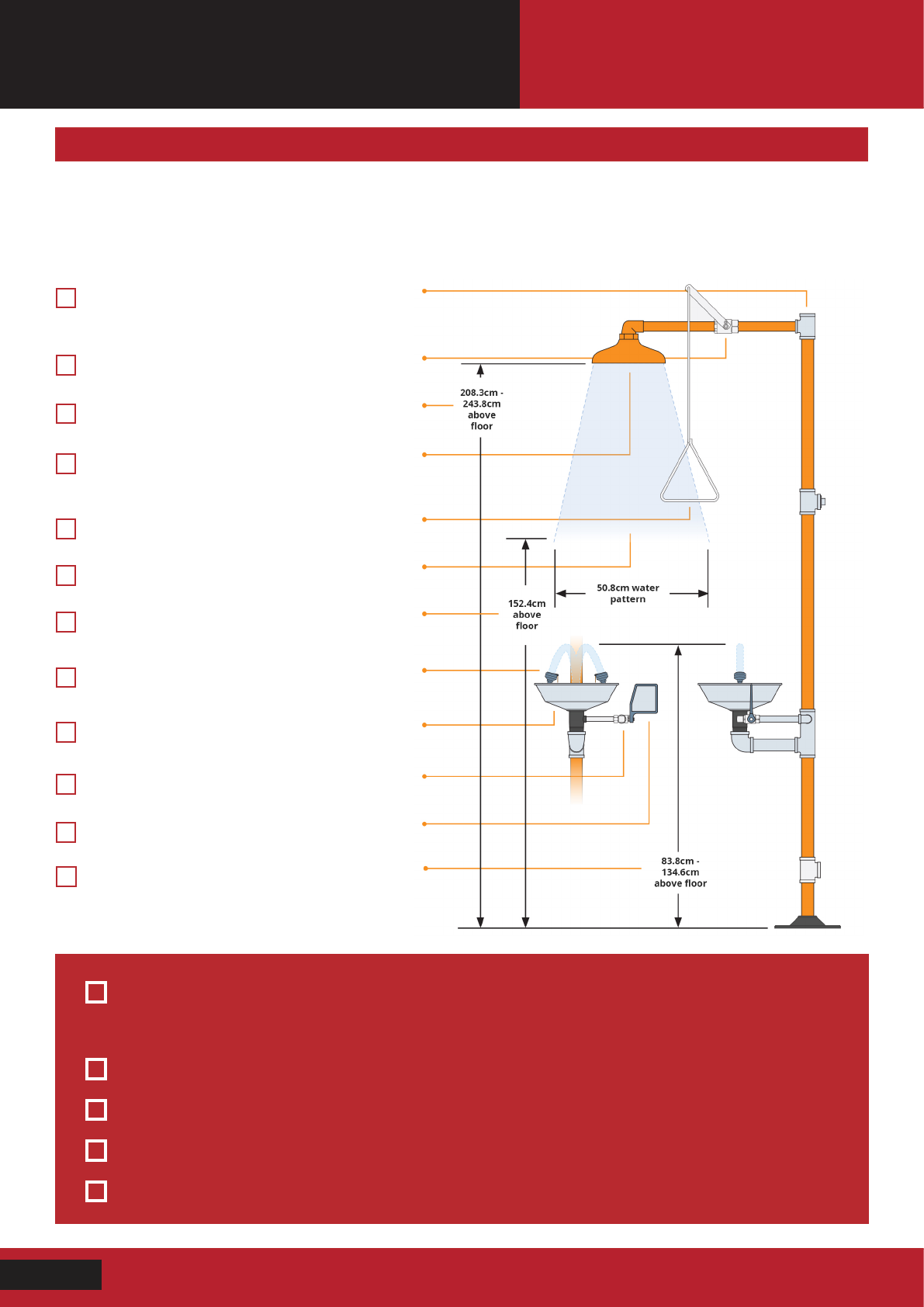

AS 4775:2007 COMPLIANCE CHECKLIST

EMERGENCY SHOWERS

This checklist is a summary of the provisions of AS 4775:2007 relating to emergency showers. Please refer to the standard for a

complete listing of these provisions.

All Guardian emergency showers are third-party certied to meet or exceed the provisions of ANSI Z358.1-2014.

Water supply is sucient to provide at least

75.7 LPM for 15 minutes.

Hands-free valve activates in one second or

less and remains open until manually closed.

Shower delivers 75.7 liters of water per

minute for 15 minutes in the required

pattern.

Height of water column is between 208.3 cm

and 243.8 cm above the oor.

Center of the water pattern is at least 40.6 cm

from any obstruction.

Easily located, accessible actuator is no more

than 173.3 cm above oor.

At 152.4 cm above the oor, the water

pattern is at least 50.8 cm in diameter.

If provided, shower enclosure has a minimum

diameter of 86.4 cm.

Location: Install shower within 10 seconds (approximately 16 m) of hazard, on the same level as hazard and

with unobstructed travel path. Where strong acids or caustics are being handled, emergency showers should be

located adjacent to the hazard, and an appropriate professional should be consulted for advice on the proper

distance.

Identication: Identify shower location with highly visible sign. Area around shower shall be well-lit.

Water Temperature: Water delivered by shower shall be tepid (16-38°C).

Training: Instruct all employees in the location and proper use of emergency showers.

Maintenance/Inspection: Activate plumbed shower at least weekly. Inspect all emergency showers annually

for compliance with standard.

www.dilnz.co.nz | Tel: 0800 323 223

9

AS 4775:2007 COMPLIANCE CHECKLIST

EYE/FACE WASHES

This checklist is a summary of the provisions of AS 4775:2007 relating to emergency eye/face washes. Please refer to the

standard for a complete listing of these provisions.

All Guardian eye/face wash units are third-party certied to meet or exceed the provisions of ANSI Z358.1-2014.

Controlled, low velocity ow completely rinses

eyes and face and is not injurious to user.

Water ow is suciently high to allow user to

hold eyes open while rinsing.

Spray heads are protected from airborne

contaminants. Covers are removed by water

ow.

Unit delivers at least 11.4 liters of water per

minute for 15 minutes.

Water ow pattern is positioned between

83.8 cm and 134.6 cm from the oor and

at least 15.3 cm from the wall or nearest

obstruction.

Hands-free stay-open valve activates in one

second or less.

Valve actuator is easy to locate and readily

accessible to user.

Unit washes both eyes simultaneously. Water

ow covers area indicated on Guardian test

gauge at no more than 20.3 cm above spray

heads.

Location: Install eye/face wash unit within 10 seconds (approximately 16 m) of hazard, on the

same level as hazard and with unobstructed travel path. Where strong acids or caustics are being handled,

emergency eye/face wash units should be located adjacent to the hazard, and an appropriate professional

should be consulted for advice on the proper distance.

Identication: Identify eye/face wash location with highly visible sign. Area around eye/face wash unit shall be

well-lit.

Water Temperature: Water delivered by eye/face wash shall be tepid (16-38°C).

Training: Instruct all employees in the location and proper use of eye/face wash units.

Maintenance/Inspection: Activate plumbed eye/face wash units at least weekly. Inspect all eye/face wash

units annually for compliance with standard.

www.dilnz.co.nz | Tel: 0800 323 223

10

AS 4775:2007 COMPLIANCE CHECKLIST

SAFETY STATIONS

This checklist is a summary of the provisions of AS 4775:2007 relating to eye or eye/face wash and shower combination stations.

Please refer to the standard for a complete listing of these provisions.

All Guardian safety stations are third-party certied to meet or exceed the provisions of ANSI Z358.1-2014.

Water supply delivers required ow when shower and

eye or eye/face wash are operated simultaneously.

Hands-free stay-open valve activates in one second or

less.

Height of water column is between 208.3 cm and 243.8

cm above the oor.

Shower delivers 75.7 liters of water per minute for 15

minutes in the required pattern.

Easily located, accessible actuator is no more than 173.3

cm above oor.

Center of the water pattern is at least 40.6 cm from any

obstruction.

At 152.4 cm above the oor, the water pattern is at least

50.8 cm in diameter.

Spray heads are protected from airborne contaminants.

Covers are removed by water ow.

Location: Install safety station within 10 seconds (approximately 16 m) of hazard, on the same level as hazard

and with unobstructed travel path. Where strong acids or caustics are being handled, safety station should be

located adjacent to the hazard, and an appropriate professional should be consulted for advice on the proper

distance.

Identication: Identify safety station location with highly visible sign. Area around safety station shall be

well-lit.

Water Temperature: Water delivered by safety station shall be tepid (16-38°C).

Maintenance/Inspection: Activate safety station at least weekly. Inspect all safety stations annually for

compliance with standard.

Training: Instruct all employees in the location and proper use of safety station.

Unit delivers at least 11.4 liters per minute (for eye/face

wash or 1.5 liters per minute (for eyewash) for 15

minutes.

Hands-free stay-open valve activates in one second or

less.

Valve actuator is easy to locate and readily accessible to

user.

Water ow pattern is positioned between 83.8 cm and

134.6 cm from the oor and at least 15.3 cm from the

wall or nearest obstruction.

www.dilnz.co.nz | Tel: 0800 323 223

11

GUARDIAN TECHNOLOGY

GUARDIAN EMERGENCY EYEWASH AND SHOWER TECHNOLOGY:

ENGINEERED FOR TODAY’S INDUSTRIAL ENVIRONMENTS.

Safe workplaces demand advanced emergency eyewash and shower equipment. Guardian is proud to oer the most complete

selection of emergency equipment designed for today’s industrial applications. Characterised by enhanced performance and

superior durability, all Guardian products feature the latest innovations in spray head technology. The unique GS-Plus™ and

FS-Plus™ spray heads deliver water in a soft, wide spray rather than a solid, narrow stream. The user receives more water over a

wider area than with any other type of outlet head. In an emergency, contaminants are ushed away quickly, gently, and completely.

These heads incorporate a variety of unique and important features:

CONSISTENT, BALANCED FLOW

An engineered ow control located inside each spray head is

calibrated to deliver 6.9 (GS-Plus™) or 12.1 (FS-Plus™) litres per

minute, at pressures from 20 to 100 PSI. The ow is consistent,

and evenly balanced between the spray heads

regardless of line pressure.

“FLIP TOP” DUST COVER

Each spray head is protected against dust and dirt by a “ip

top” cover which nests into the top of the outlet head when

equipment is not in use. Upon unit activation, water ow

swings the cover o the head. The cover is permanently

attached to the spray head by a stainless steel pin to pre-

vent removal or loss. Optional stainless steel covers are also

available.

FILTERED WATER

Each spray head contains an internal lter to

remove particles and debris from the water ow. During

ushing, the user’s eyes and face are protected against

any potential foreign matter which may exist in the water

or plumbing lines.

DURABILITY

The spray head bodies are molded from

tough, impact-resistant and corrosion

resistant polypropylene, while the “ip top”

dust covers are molded nylon. Both the

GS-Plus™ and FS-Plus™ spray heads stand up

to the harshest laboratory environments.

EASY MAINTENANCE

Water often contains dissolved minerals and

foreign matter which, over time can build up

and clog any spray head. The GS-Plus™ and

FS-Plus™ spray heads are designed such

that all working components are contained

within the head itself, making cleaning and

maintenance easy. Guardian’s emergency

equipment should never need disassembly in

the event of a clogged spray head.

www.dilnz.co.nz | Tel: 0800 323 223

12

INSTALLATION AND MAINTENANCE

>>SHOWERS

>>COMBINATION SHOWER-EYEWASH

>>COMBINATION SHOWER-EYE/FACE WASH

INSTALLATION

Unit should be assembled in accordance with the

manufacturer’s drawing, installed in close proximity to

hazard and should be in a location clearly identied and

free of obstructions.

Shut-o valve(s) (supplied by others) should be installed and

located in accordance with the local plumbing code.

Back ow prevention device(s) (supplied by others) should be

installed and located in accordance with the local plumbing

code.

Drain location and waste discharge should be installed and

located in accordance with the local plumbing code.

Mixing valve(s) (supplied separately) should be installed and

located in accordance with the Uniform Plumbing Code.

Shower head should be located between 82 and 96 inch-

es from the surface on which the user stands and center

of spray pattern should be at least 16 inches from any

obstruction.

Eye or eye/face wash water ow pattern shall be positioned

between 33 and 53 inches from the oor and at least 6

inches from the wall or nearest obstruction.

Handicap accessible units intended to meet ADA

requirements will have dierent eye/face wash clearance

requirements. Please refer to enclosed drawings.

Unit should be connected with a recommended

minimum 1” IPS line to a tepid, clean water source

capable of supplying 30-80 PSI owing pressure

for a minimum of 15 minutes. If shut-o valves are

installed inline, provisions should be made to prevent

unauthorized shut o.

Where freezing conditions exist, unit must be protected

from freezing.

Performance should be veried after installation. Check for

any leaks while all valves are in the closed position. Verify

that all

valves stay in the open position upon activation.

With the shower valve in the fully opened position, spray

pattern should be a minimum of 20 inches in diameter

at 60 inches above the surface on which the user stands.

Verify that the water is tepid and ow rate is at least 20

GPM.

With the eyewash valve in the fully opened position and

using a test gauge, the spray pattern should meet required

pattern per ANSI Z358.1. Verify that the water is tepid, and

ow rate is at least 0.4 GPM for eyewash and 3.0 GPM for

eye/face wash.

MAINTENANCE

All units should be tested on a weekly basis to clear supply

lines and verify proper activation. Units must also be inspected

annually to verify the continued conformance of required

performance standards stated above.

>>EYEWASH

>>EYE/FACE WASH

>>DRENCH HOSE

INSTALLATION

Unit should be assembled in accordance with the

manufacturer’s drawing, installed in close proximity to

hazard and should be in a location clearly identied and

free of obstructions.

Shut-o valve(s) (supplied by others) should be installed

and located in accordance with the local plumbing code.

Back ow prevention device(s) (supplied by others) should

be installed and located in accordance with the local

plumbing code.

Drain location and waste discharge should be installed and

located in accordance with the local plumbing code.

Mixing valve(s) (supplied separately) should be installed

and located in accordance with the Uniform Plumbing

Code.

Eye or eye/face wash water ow pattern shall be positioned

between 33 and 53 inches from the oor and at least 6

inches from the wall or nearest obstruction.

Handicap accessible units intended to meet ADA

requirements will have dierent eye/face wash clearance

requirements. Please refer to enclosed drawings.

Unit should be connected with a recommended minimum

1/2” IPS line to a tepid, clean water source capable of

supplying 30-80 PSI owing pressure for a minimum of 15

minutes. If shut-o valves are installed inline, provisions

should be made to prevent unauthorized shut o. Note:

Do not use 3/8” nominal ex connector as ow may be

insucient.

Where freezing conditions exist, unit must be protected

from freezing.

Performance should be veried after installation. Check

for any leaks while all valves are in the closed position. All

valves should stay in the open position upon activation.

With the eyewash valve in the fully opened position and

using a test gauge, the spray pattern should meet required

pattern per ANSI Z358.1. Verify that the water is tepid, and

ow rate is at least 0.4 GPM for eyewash and 3.0 GPM for

eye/face wash.

MAINTENANCE

All units should be tested on a weekly basis to clear supply

lines and verify proper activation. Units must also be inspected

annually to verify the continued conformance of required

performance standards stated above.

Drench Hose Note:

Do not exceed 90 PSI working pressure. Inspect at least

monthly for wear, abrasion, loss of exibility or loosening of end

connections. For use with water in accessible locations only.

www.dilnz.co.nz | Tel: 0800 323 223

13

CORROSIVE RESISTANCE GUIDE

Standard emergency eye wash and shower equipment is constructed from a variety of materials, including stainless steel (shower

pull rods and actuating arms), chrome plated brass (valves and eye wash components) and galvanized steel (pipe and ttings). In

addition, standard units may include plastic components (shower heads, eye wash bowls, spray heads, etc.) that are molded from

ABS, polypropylene and/or nylon.

When installed in industrial environments, emergency eye wash and shower equipment is exposed to all of the conditions present

in the environment, including temperature, humidity, sunlight and chemicals that may be present. In particular, the equipment

can be exposed to acids, caustics and other chemicals that will cause the materials in the equipment to corrode. Such corrosion

is a serious matter, since it can cause the equipment to deteriorate to the point of becoming nonfunctional. In an emergency,

the equipment may not be available to an injured person. While Guardian carefully selects the materials used in its products, the

possibility of corrosion cannot be eliminated.

Guardian oers several alternatives for improving the corrosion resistance of emergency equipment:

Powder Coated Finish. All of our units can be furnished with a powder coated nish applied over the galvanized steel and brass

components. The surfaces to be coated are cleaned and etched with phosphoric acid solution. Epoxy/polyester hybrid pow-

der is electrostatically applied to the metal surfaces and then baked to cure. The result is a smooth, hard surface that provides

excellent resistance to corrosion. Guardian powder coating is available in a variety of colors, including high visibility orange,

green, yellow and red. These colors provide the equipment with increased visibility in the industrial environment.

Polyvinyl Chloride (PVC) Construction. Guardian oers a wide array of units that are constructed of PVC and PVC-coated ma-

terials. All pipe and ttings are PVC. Valves, actuators and other components are brass with a PVC coating. These units can

provide better durability than standard emergency equipment in certain environments.

Stainless Steel. Guardian also oers a wide selection of units that are constructed entirely of stainless steel. These units are

highly resistant to corrosion, and are ideal for use in areas such as laboratories and clean rooms.

In order to assist in selecting the equipment that is best suited for a particular application, Guardian has compiled a “Corrosion

Resistance Guide”. This corrosion information is oered as a guideline only, to assist in selecting the equipment that will be best

suited for the user’s application.

Due to the innite number of combinations of chemicals found in any environment, as well as the eects of chemical

concentration, temperature, humidity, etc., Guardian cannot predict and cannot be held responsible for the eects of any

particular environment on any specic installation of emergency eye wash and shower equipment.

www.dilnz.co.nz | Tel: 0800 323 223

14

CORROSIVE RESISTANCE GUIDE

www.dilnz.co.nz | Tel: 0800 323 223

15

CORROSIVE RESISTANCE GUIDE

Notes:

The above table presents the relative corrosion resistant abilities of certain materials in the specic corrosive environments

described. This information should be considered as a general guide only. The table does not provide information on possible

combinations of concentrations of corrosive media or temperature levels that may be found in the eld. Even small changes

in the concentration of the corrosive media or in the temperature at which interaction takes place may generate dierent

results from those described above. Results dierent from those shown above may also result from impurities in the metals

or plastics, the actual condition of the environment in which the materials are used, or other factors.

NO GUARANTEE OF THE PERFORMANCE OF ANY METAL OR PLASTIC DESCRIBED IN THE TABLE IS EXPRESSED OR SHOULD BE IN-

FERRED. GUARDIAN RECOMMENDS THAT MATERIAL SAMPLES BE SUBJECTED TO ACTUAL OPERATING CONDITIONS BEFORE FINAL

SPECIFICATION.

The corrosion resistance data for powder coating is based upon laboratory testing consisting of subjecting coated samples

to drops of the listed chemicals for ten minutes. Dierent results may be obtained when coated materials are subjected to

chemicals for longer periods of time.

DALTON INTERNATIONAL LIMITED

Physical Address: Unit 6, 23 Ash Road, Wiri, Auckland, 2104

Postal Address: PO Box 259041, Botany, Auckland, 2163

Tel: 0800 323 223 or +64 09 263 3142 | Web: www.daltoninternational.co.nz | Email: [email protected]

DISTRIBUTED BY