Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

1

PROCESS CONTROL LAB

LAB MANUAL

For Temperature Control Trainer

List of Experiments:-

1. To study Tuning of controller (Using Auto Tuning method)

2. Study of open loop response (Manual control)

3. Study of on/off controller

4. Study of proportional controller

5. Study of proportional integral controller

6. Study of proportional derivative controller

7. Tuning of controller (Open loop method)

8. Tuning of controller (Closed loop method)

9. To study Tuning of controller (Using Auto Tuning method)

10. Study of stability of the system (Bode plot)

For Pressure Control Trainer

List of experiments:-

1. To study of open loop response (manual control)

2. To study of on/off controller.

3. To study of proportional controller

4. To study of proportional integral controller

5. To study of proportional derivative controller

6. To study of proportional integral derivative controller

7. To tuning of controller (open loop method)

8. To tuning of controller (closed loop method)

9. To tuning of controller (using auto tuning method)

10. To study stability of the system (Bode plot)

For Level Control Trainer

List of experiments:-

1. To study of open loop response (manual control)

2. To study of on/off controller.

3. To study of proportional controller

4. To study of proportional integral controller

5. To study of proportional derivative controller

6. To study of proportional integral derivative controller

7. To tuning of controller (open loop method)

8. To tuning of controller (closed loop method)

9. To tuning of controller (using auto tuning method)

10. To study stability of the system (Bode plot)

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

2

Temperature Control Trainer

1. Aim of the experiment:-

Study of open loop response (Manual control)

Apparatus required:-

Temperature Control Trainer

Theory: - :- Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

Procedure

Start up set up as explained in general instructions.

Click Select Experiment, select Open Loop and click Start

Decrease the controller output to 0%. Note down steady state process value.

Apply the step change by 10% to controller output and wait for the temperature to reach

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

3

the steady state value. Note down the process value.

Repeat the above step until the controller output reaches to maximum i.e. 100% and for

each change, note steady state process value.

Observations

Tabulate the observations as follows

Controller output in %

Process Value in

0

C

0

10

20

…

100

From the above data, note the output required for maintaining the temperature at desired

set points.

2. AIM OF THE EXPERIMENT:-

Study of on/off controller

Apparatus required:-

Temperature Control Trainer

THEORY: - :- Temperature control trainer is designed for

understanding the basic temperature

control

principles. The process setup consists of heating tank fitted with SSR controlled heater for

on-line heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

4

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select On-Off Mode and click Start

Change Hysteresis value to 1 %.( Range 0.1-10%)

Change the values of the set point and observe the On-Off control operation.

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

5

Observations

Observe that if process value exceeds the set point and increases than the value of (0.5x

Hysteresis), controller switches off the SSR and if process value decreases below the set point by

(0.5 x Hysteresis), SSR switches on i.e. controller operates like On/Off switch.

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

6

3. Aim of the experiment:-

Study of proportional controller

Apparatus required:-

Temp. Control trainer

Theory: - Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

Procedure

Start up set up as explained in general instructions.

Click Select Experiment, select P Mode and click Start

Keep the set point to 40%. (Set point should be 10% more than inlet water temperature)

Change output mode to Manual. Adjust output value so as to match the process value with

set point and apply this output value as bias value to the controller. Adjust the proportional

band to 50%.

Switch the controller to Auto mode.

Apply step change to set point, step change should be of 2 to 3 % and observe the response.

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

7

Switch the controller to Manual mode. Decrease proportional band to half of the previous

value & then shift controller to Auto mode. With each decrease, obtain a new response of

the step change. Ensure that the set point changes are around the same operating point (@

2-

3% only).

Using trial and error approach, find a value of proportional band so that the response to a

step change has at most one overshoot and one undershoot.

Set the controller to the settings obtained in the above step and wait for the system to

reach at

steady state.

Observations

Observe steady state error decreases as proportional band decreases.

Observe the effect of very low proportional band values (system works in oscillatory mode).

Observe the response of the system to load change. Load change can be given by slightly

varying the inlet flow rate.

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

8

4. Aim of the experiment:

To Study of proportional integral controller

Apparatus required:-

Temp control trainer

Theory: - Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

Procedure

Start up set up as explained in general instructions.

Click Select Experiment, select PI Mode and click Start

Adjust the process value by changing the output of controller in manual mode to a particular

temperature (set point =40%).

Set the proportional band estimated from Proportional control (from previous experiment).

Start with derivative time=0 and integral time=1000 sec., which will cut off the derivative

action and widen the effect of integral action.

Allow the process to reach at steady state. Record the steady state error.

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

9

Switch on the controller to manual mode. Reduce the integral time to half of the previous

value. Switch to Auto mode and apply step change to the set point by 2 to 3%. Note the

response of the system.

Using trial and error, find out an integral time, which gives satisfactory response to the step

change in set point.

Observations

Observe the effect of reducing integral time on offset and on the response of the process.

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

10

5. Aim of the experiment:-

To Study of proportional derivative controller

Apparatus required:-

Temp control trainer

Theory: - Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

Procedure

Start up set up as explained in general instructions.

Click Select Experiment, select PD Mode and click Start

Set the proportional band estimated from Proportional control (P only). Start with derivative

time=0 and integral time=6000 sec., which will cut off the derivative action and widen the

effect of integral action.

Set the set point to desired temperature (@40%). Allow the process to reach at steady state.

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

11

Note the response of the system.

Switch on the controller to manual mode. Increase the derivative time by 1 sec. Switch to

Auto mode and apply step change to the set point by 2 to 3%. Note the response of the

system.

Increase the derivative time gradually and observe the process response for step change.

Observations

Observe the effect of increasing derivative time. Also note that the process may show offset

as effect of integral action is cut off.

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

12

6. Aim of the experiment:-

To Study of proportional integral derivative controller

Apparatus required:-

Temperature control trainer

Theory: - Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

13

Procedure

Start up set up as explained in general instructions.

Click Select Experiment, select PID mode and click Start

Switch the controller to manual mode.

Change the proportional band to the value that estimated in proportional controller. Set

integral time and derivative time based on the responses in previous experiments.

Change the controller to Auto mode. Apply step change by 2 to 3% to the set point and

observe the response of the process.

Change the proportional band, integral time, derivative time and observe the response of

the process for step change for each change in setting.

Observations

Compare the steady state response of the PID controller with P, PI and PD controller

obtained in the previous experiments.

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

14

7. Aim of the experiment:-

To study Tuning of controller (Open loop method)

Apparatus required:-

Temp.control trainer

Theory: - Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

15

Procedure

Start up set up as explained in general instructions.

Click Select Experiment, select Process Reaction and click Start

Adjust the controller output and bring the process near set point of 40%.

Allow the system to reach steady state. Start data logging.

With the controller still in manual mode impose a step change of 30 - 40 % in

controller output. Record the step response. Wait for the steady state. Stop data

logging.

Plot the step response (Process reaction curve) from stored data. Find out the value of slope

at

the point of inflection and time lag.

Calculate P I D settings for different modes.

Select PID Mode option for control from software. (Click on “Change Expt.” Button, click

on

“Change”, Click on “PID Mode” button.) Switch on the controller to manual mode and

Keep

the set point to 40%. Adjust output value so as to match the process value to set

point.

Set the PID values obtained from the calculations. Switch on the controller to Auto mode.

Apply the step change & observe the response of the system. Allow the system to reach

steady state.

Observations

(Refer Theory process control for formula.)

Step change to the system P = Initial output- Final output of the controller.

Plot the graph of process value Vs Time on a graph paper.

From process reaction curve:

o Slope of the process reaction curve R =

o Time lag L=

Calculate P, PI, and PID setting from above values.

Observe response of the system for different PID settings.

17-04-2017

16

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

8. Aim of the experiment:-

To study Tuning of controller (Closed loop method)

Apparatus required:-

Temp. Control trainer

Theory: - Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

Procedure

Start up set up as explained in general instructions.

Click Select Experiment, select Close Loop and click Start

Set the proportional band value to maximum (Say 100). Set the controller to manual mode

and adjust the output so that the process is nearly at set point 40%.

Set controller to auto mode and impose step on the process by moving the set point for a

few seconds & then return to its original value (or apply the step change to the set point of

2%). Wait for some time & observe the response.

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

17-04-2017

17

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Decrease the proportional band to the half of previous and impose step on the process as

mentioned above. Wait for some time & observe the response.

Repeat the above procedure and find out correct value of proportional band for which the

system just goes unstable i.e. continuous oscillations are observed in the output of

controller.

Record the ultimate proportional band and ultimate period from the response.

Calculate the PID values from the table. Select the PID controller and apply the parameter

values obtained from the above steps. Observe the response of the process to a step change

with these settings.

Observations

Record the ultimate proportional band (Pbu) and ultimate period (Tu) from above

experiment.

Calculate PID values by referring theory part for different control actions.

Observe the process response for these settings.

Compare the values obtained with open loop response me

17-04-2017

18

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

9. Aim of the experiment:-

To study Tuning of controller (Using Auto Tuning method)

Apparatus required:-

Temperature control trainer

Theory: - Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring

the process in SCADA mode.

Solid State Relay

Electric Supply

Set Point

Rotameter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

17-04-2017

19

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select Autotune and click Start

Wait Till Auto tune is complete. (Blinking of green LED stops).

Controller automatically finds the PB, IT & DT values.

Find out PID values at different set points /flow rates.

Observations

The controller has preprogrammed logic for finding “Auto tune” values. Based on the

response of the process the controller calculates PID values or comes out without finding the

“Auto tune” values.

17-04-2017

20

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

10. Aim of the experiment:-

Study of stability of the system (Bode plot)

Apparatus required:-

Temp control trainer

Theory: - Temperature control trainer is designed for

understanding the basic temperature control

principles. The process setup consists of heating tank fitted with SSR controlled heater for on-line

heating of the water. The flow of water can be manipulated and measured by

rotameter.

Temperature sensor (RTD) is used

for temperature sensing. The process parameter (Temperature) is

controlled by microprocessor based digital indicating controller which manipulates heat input to

the process. These units along with necessary

piping and fitting are mounted on support frame

designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring

the process in SCADA mode.

Procedure

Start up set up as explained in general instructions.

Click Select Experiment, select Stability analysis and click Start

Solid State Relay

Electric Supply

Set

Point

Rota meter

Temperature

Controller

Temperature Sensor

Water Supply

Heater Heating Tank

Drain

17-04-2017

21

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Select function generator to apply the sinusoidal input to the output of the controller.

Enter Reference point, Amplitude and Period.

Observe the sinusoidal output of the controller and sinusoidal response of the process.

Log the data for records.

Change the period and repeat the observation for 3-4 different values of the period.

Note

: As the temperature process is very slow responsive, the amplitude and period for the

sinusoidal input should be large enough to observe response.

Observations

Form the data file stored note down the

Observe the output response of the process and note down the output amplitude. Measure

output wave period and note down as T sec. Measure the phase lag x and note down in sec.

Obs.

No.

Input

amplitude

A1 %

Output

amplitude

A2 %

Output Period

T in sec

Lag X

In sec

Frequency

Calculations

Calculate for each observation

Magnitude ratio as M =

A2/A1 Phase angle = (X/T)

x 360 Frequency = 1/T

cycles

/

sec.

17-04-2017

22

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Draw the graphs of:

Magnitude Vs frequency on log - log scale

Phase angle Vs frequency on semi-log coordinates.

Study the graph for stability conditions mentioned in theo

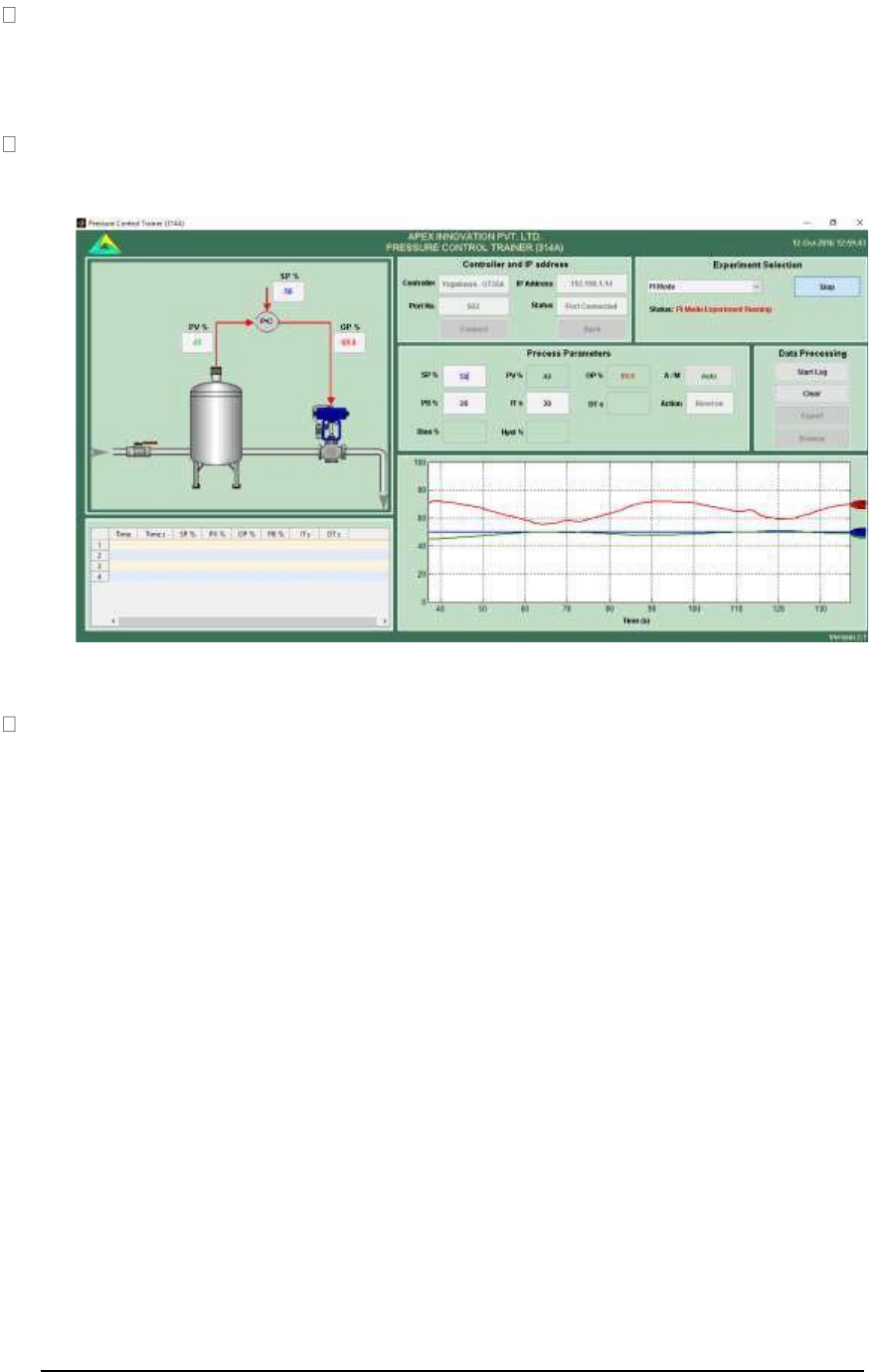

FOR PRESSURE CONTROL TRAINER

1. Aim of experiment:-

To Study of open loop response (Manual control)

Apparatus Required:-

Pressure control Trainer

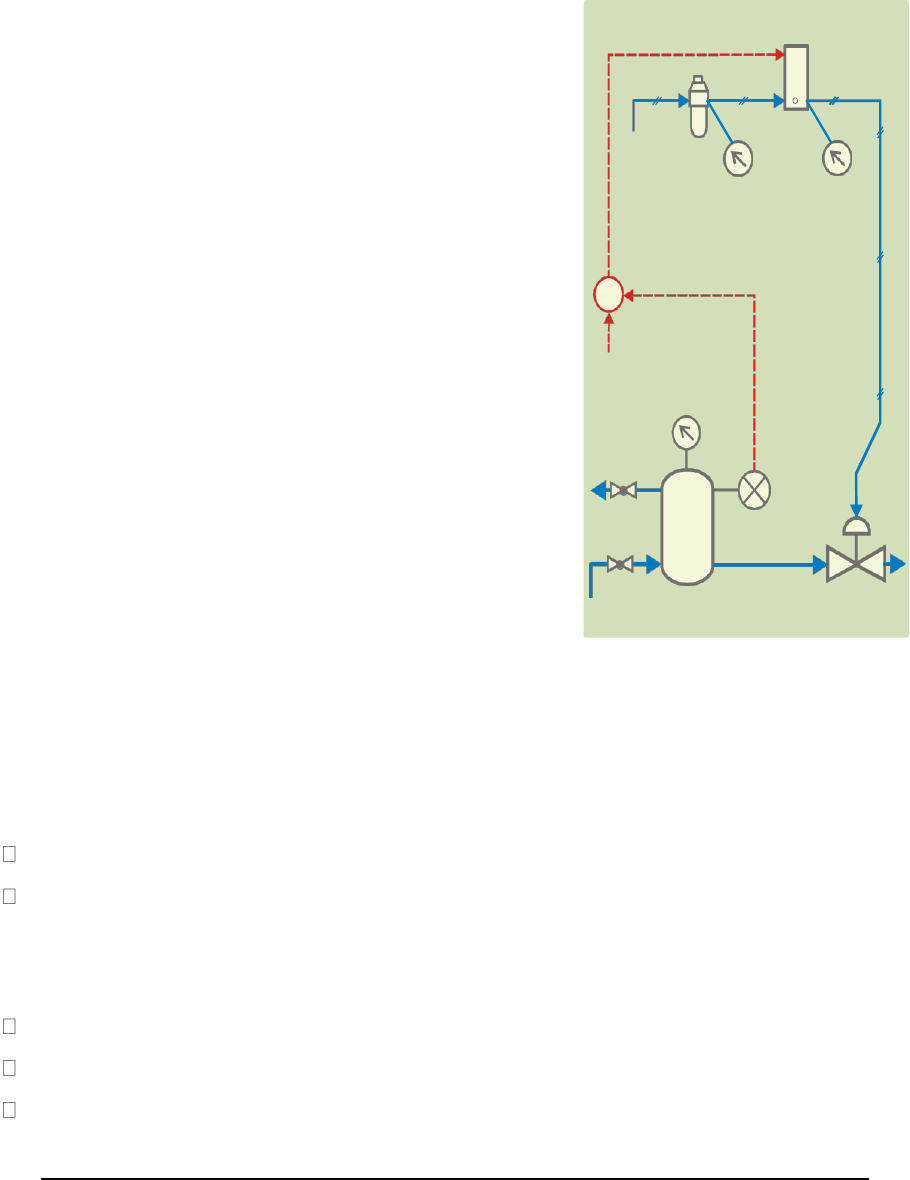

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select Open Loop and click Start

Close the control valve by increasing the controller output to 100%. Note down steady state

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

23

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

process value.

Apply the step change by 10% to controller output and wait for the process value to reach the

steady state value. Note down the process value.

Repeat the above step until the controller output reaches to minimum 0%.

Observations

Tabulate the observations as follows

Controller output in %

Process Value in %

100

90

80

…

0

From the above data, note the output required for maintaining the process at desired set

points. (For particular vent valve opening).

Set the output of the controller to the noted value and at steady state apply the load change to the

process. Load change can be given by slightly varying the vent valve. Observe new steady state

process value.

17-04-2017

24

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

2. Aim of the experiment:-

To Study of on/off controller

Apparatus required:-

Pressure control trainer

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select On-Off Mode and click Start

Change Hysteresis value to 1 %.( Range 0.1-10%)

Change the values of the set point and observe the On-Off control operation.

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

25

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Observations

Observe that if process value exceeds the set point and increases above the value of (0.5x

Hysteresis), control valve is full open and if process value decreases below the set point by (0.5

x Hysteresis), the control valve closes fully i.e. controller operates like On/Off switch.

17-04-2017

26

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

3. Aim of the experiment:-

Study of proportional controller

Apparatus required:-

Pressure control trainer

Theory: - - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general

instructions.

Click Select Experiment, select P Mode and click Start

Keep the set point to 60%. Change output mode to Manual. Adjust output value so as to

match the process value with set point and apply this output value as bias value to the

controller. Adjust the proportional band to 50%.

Switch the controller to Auto mode.

Apply step change of 10% to set point and observe the response.

Switch the controller to Manual mode. Decrease proportional band to half of the previous

value & then shift controller to Auto mode. With each decrease, obtain a new response of

the

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

27

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

step change. Ensure that the set point changes are around the same operating point (@

5-10%

only).

Using trial and error approach, find a value of proportional band so that the response to a step

change has at most one overshoot and one undershoot.

Set the controller to the settings obtained in the above step and wait for the system to reach at

steady state.

Observations

Observe steady state error decreases as proportional band decreases.

Observe the effect of very low proportional band values (system works in oscillatory mode).

Observe the response of the system at load change. Load change can be given by slightly

manipulating the vent valve of the tank.

Study of proportional integral controller

17-04-2017

28

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

4. Aim of the experiment:-

Study of proportional integral controller

Apparatus required:-

Pressure control trainer

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general

instructions.

Click Select Experiment, select PI Mode and click Start

Adjust the process value by changing the output of controller in manual mode to a particular

pressure (set point =60%).

Set the proportional band estimated from Proportional control (from previous experiment).

Start with derivative time=0 and integral time=1000 sec., which will cut off the derivative

action and widen the effect of integral action.

Set the set point to desired pressure (@60%). Allow the process to reach at steady state.

Record the steady state error.

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

29

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Switch on the controller to manual mode. Reduce the integral time to half of the previous

value. Switch to Auto mode and apply step change to the set point by 2 to 3%. Note the

response of the system.

Using trial and error, find out an integral time, which gives satisfactory response to the step

change in set point.

Observations

Observe the effect of reducing integral time on offset and on the response of the process.

17-04-2017

30

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

5. Aim of the experiment:-

Study of proportional derivative controller

Apparatus required:-

Pressure control trainer

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general

instructions.

Click Select Experiment, select PD Mode and click Start

Select PD controller. Set the proportional band estimated from Proportional control (P only).

Start with derivative time=0 and integral time=6000 sec., which will cut off the derivative

action and widen the effect of integral action.

Set the set point to desired pressure (@60%). Allow the process to reach at steady state.

Note

the response of the system.

Switch on the controller to manual mode. Increase the derivative time by 1 sec. Switch to

Auto mode and apply step change to the set point by 2 to 3%. Note the response of the

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

31

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

system.

Increase the derivative time gradually and observe the process response for step change.

Observations

Observe the effect of increasing derivative time. Also note that the process may show offset

as

effect of integral action is cut off.

17-04-2017

32

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

6. Aim of the experiment:-

Study of proportional integral derivative controller

Apparatus required:-

Pressure control trainer

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general

instructions.

Click Select Experiment, select PID mode and click Start

Switch the controller to manual mode.

Change the proportional band to the value that estimated in proportional controller. Set

integral time and derivative time based on the responses in previous experiments.

Change the controller to Auto mode. Apply step change by 2 to 3% to the set point and

observe the response of the process.

Change the proportional band, integral time, derivative time and observe the response of

the

process for step change for each change in setting.

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

33

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Observations

Compare the steady state response of the PID controller with P, PI and PD controller

obtained in the previous experiments.

17-04-2017

34

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

7. Aim of the experiment:-

Tuning of controller (Open loop method)

Apparatus required:-

Pressure control trainer

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general

instructions.

Click Select Experiment, select Process Reaction and click Start

Adjust controller output, so that the process value is maintained at 60%.

Start data logging.

With the controller still in manual mode impose a step change apply a 20 - 30 % change to

controller output. (Open the control valve) Record the step response. Wait for the steady

state.

Stop data logging.

Plot the step response (Process reaction curve) from stored data. Find out the value of slope

at the

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

35

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

point of inflection and time lag.

Calculate P I D settings for different modes.

Select PID Mode option for control from software. (Click on “Change Expt.” Button, click on

“Change”, Click on “PID Mode” button.) Switch on the controller to manual mode and Keep

the set point to 60%. Adjust output value so as to match the process value to set point.

Set the PID values obtained from the calculations. Switch on the controller to Auto mode.

Apply the step change & observe the response of the system. Allow the system to reach

steady state.

Observations:-

(Refer Theory process control for formula.)

Step change to the system P = Initial output - Final output of the controller.

Plot the graph of process value Vs Time on a graph paper.

From process reaction curve:

Slope of the process reaction curve R =

Time

lag L=

Calculate P, PI, and PID setting from above values.

Observe response of the system for different PID settings.

17-04-2017

36

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

8. Aim of the experiment:-

To study the Tuning of controller (Closed loop method)

Apparatus required:-

Pressure control trainer

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general

instructions.

Click Select Experiment, select Close Loop and click Start

Set the proportional band value to maximum (Say 100). Set the controller to manual mode

and

adjust the output so that the process is nearly at set point (60%).

Set controller to auto mode and impose step on the process by moving the set point for a few

seconds & then return to its original value (or apply the step change to the set point of 5%).

Wait for some time & observe the response.

Decrease the proportional band to the half of previous and impose step on the process as

mentioned above. Wait for some time & observe the response.

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

37

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Repeat the above procedure and find out correct value of proportional band for which the

system just goes unstable i.e. continuous oscillations are observed in the output of

controller.

Record the ultimate proportional band and ultimate period from the response.

Calculate the PID values from the table. Select the PID controller and apply the parameter

values obtained from the above steps. Observe the response of the process to a step change

with

these settings.

Observations

Record the ultimate proportional band (Pbu) and ultimate period (Tu) from above

experiment.

Calculate PID values by referring theory part for different control actions.

Observe the process response for these settings.

Compare the values obtained with open loop response method.

17-04-2017

38

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

9. Aim of the experiment:-

To study the Tuning of controller (Using Auto Tuning method)

Apparatus Required:-

Pressure control trainer

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general

instructions.

Click Select Experiment, select Auto tune and click Start

Wait Till Auto tune is complete. (Blinking of green LED stops).

Controller automatically finds the PB, IT & DT values.

Find out PID values at different set points /vent valve positions rates.

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

39

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

17-04-2017

40

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

10. Aim of the experiment:-

To study stability of the system (Bode plot)

Apparatus required:-

Pressure control trainer

Theory: - Pressure control trainer is

designed for

understanding the basic

principles of pressure

control. The process

set up consists of

pressure vessel fitted with

pneumatic control

valve. Pressure

transmitter is used for pressure sensing.

The process parameter (Pressure) is

controlled by microprocessor based digital

indicating controller which

manipulates

pneumatic control valve fitted at

Outlet of pressure tank outlet through I/P

converter. These units along with necessary

piping are fitted on support housing designed

for tabletop mounting.

The controller can be connected to computer

through Ethernet /USB port for monitoring

the process in SCADA mode.

Procedure:-

Start up set up as explained in general

instructions.

Click Select Experiment, select Stability analysis and click Start

Select function generator to apply the sinusoidal input to the output of the controller.

Enter Reference point, Amplitude and Period.

Observe the sinusoidal output of the controller and sinusoidal response of the process.

Log the data for records.

Change the period and repeat the observation for 3-4 different values of the period.

I/P Converter

Air Regulator

Air Supply

Supply Signal

Pressure

Pressure

Pressure Controller

Set Point

Tank

Pressure

Pressure

Vent Valve

Transmitter

N

N

Air

Process Tank

Control Valve

Supply

17-04-2017

41

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Observations

Form the data file stored note down the

Observe the output response of the process and note down the output amplitude. Measure

output wave period and note down as T sec. Measure the phase lag x and note down in sec.

Obs.

No.

Input

amplitude

A1 %

Output

amplitude

A2 %

Output Period

T in sec

Lag X

In sec

Frequency

Calculations

Calculate for each observation

Magnitude ratio as M = A2/A1

Phase angle = (X/T) x 360

Frequency = 1/T cycles

/

sec.

Draw the graphs of: Magnitude Vs frequency on log - log scale

Phase angle Vs frequency on semi-log coordinates.

Study the graph for stability conditions mentioned in theory

17-04-2017

42

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

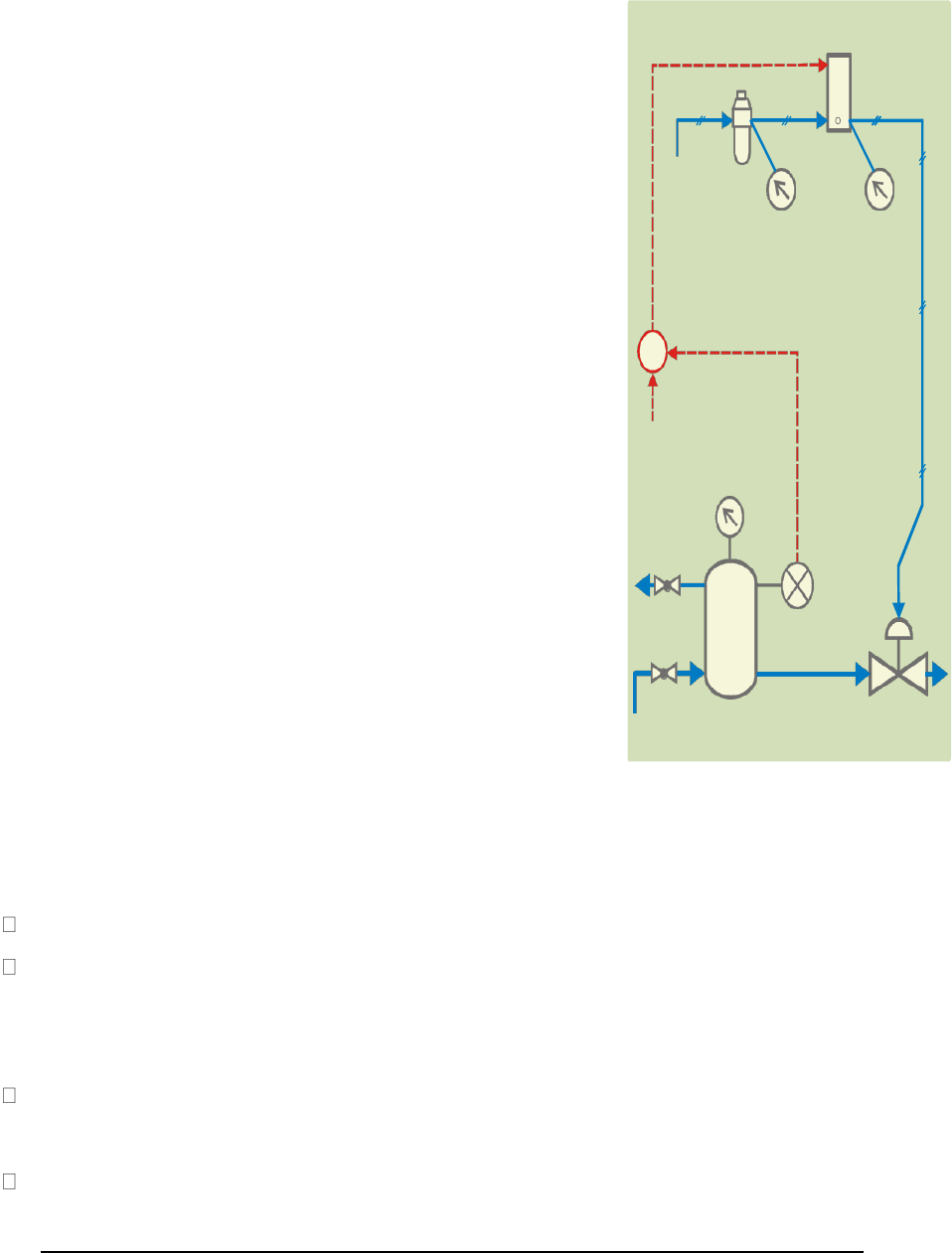

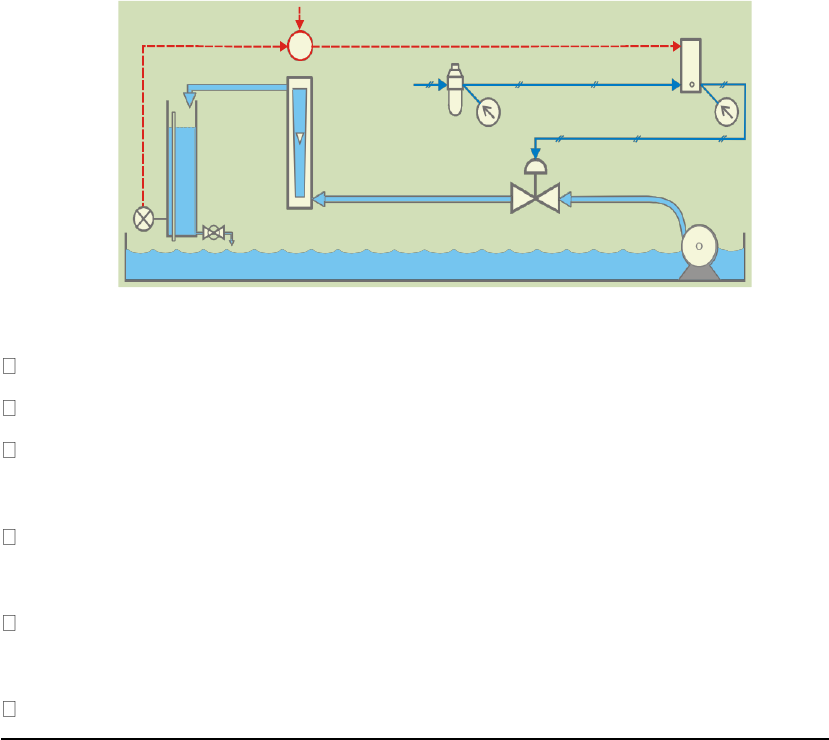

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

Level Control Trainer

1.Aim of the experiment:-

To Study of open loop response (Manual control)

Apparatus required:-

Level control Trainer

Theory: - Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select Open Loop and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click on

Auto, Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and 100%

Change the controller to Auto mode

Close the control valve by increasing the controller output to 100%.

Apply the step change by 10% to controller output in manual mode, wait for the level

17-04-2017

43

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

to reach the steady state value.

Repeat the above step until the controller output reaches to minimum i.e. 0%.

Observations

Tabulate the results as follows

Controller output in

%

Process Value in %

100

90

…

0

From the above data, note the output required for maintaining the level at desired set

points. (For particular drain valve opening).

Set the output of the controller to the noted value and at steady state apply the load change

to the process. Load change can be given by slightly varying the drain valve. Observe new

steady state process value.

17-04-2017

44

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

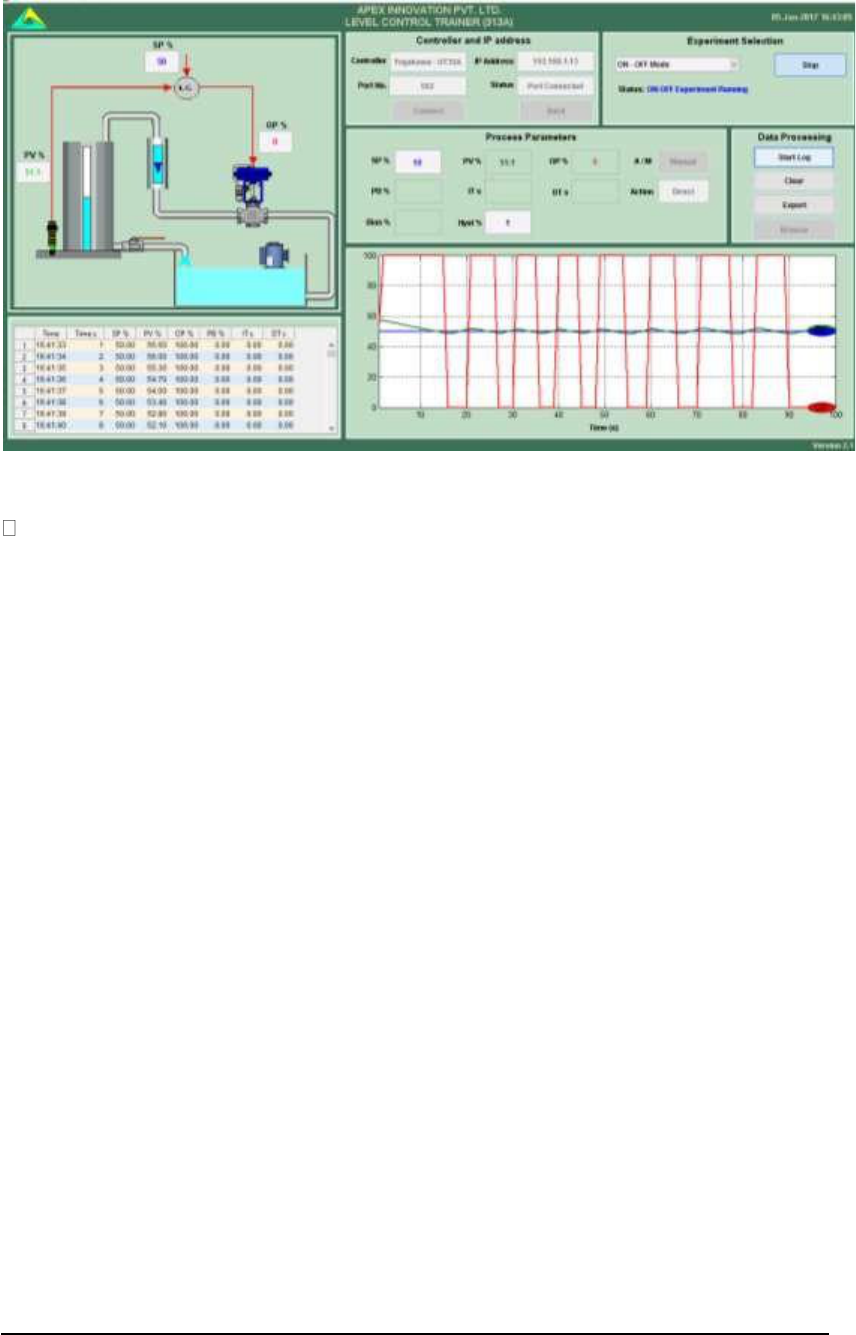

2.Aim of the experiment:--

To Study of on/off controller

Apparatus Required:-

Level control Trainer

Theory: - - Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select On-Off Mode and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click on Auto,

Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and 100%

Change

the controller to Auto mode

Change Hysteresis value to 5%.(Range 0.1-10%)

Change the values of the set point and observe the On-Off control operation.

17-04-2017

45

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Observations

Observe that if process value exceeds the set point and increases above the value of (0.5x

Hysteresis), control valve is fully closed and if process value decreases below the set point by

(0.5 x Hysteresis), the control valve opens fully i.e. controller operates like On/Off switch.

17-04-2017

46

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

3. Aim of the experiment:-

Study of proportional controller

Apparatus Required:-

Level control Trainer

Theory: - Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select P Mode and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click on Auto,

Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and 100%

Change

the controller to Auto mode

Adjust the process value by switching the controller to manual mode to a particular level (say 50

%) on the screen and apply output of the controller as bias value. Change the proportional band

to 100%.

Switch the controller to auto mode.

Apply step change of 10% to set point.

17-04-2017

47

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Switch the controller to manual mode. Decrease proportional band to half of the previous

value. With each decrease, obtain a new response of the step change. Ensure that the set

point changes are around the same operating point (Say 50%).

Observations

Observe the effect of very low proportional band values (system works as on-off control).

Observe the response of the system at load change. Load change can be given by slightly

manipulating the drain valve of the tank.

17-04-2017

48

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

4 .Aim of the Experiment:-

Study of proportional integral controller

Apparatus Required:-

Level Control Trainer

Theory: - Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select PI Mode and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click on

Auto, Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and 100%

Change the controller to Auto mode

Set the proportional band estimated in Proportional control. Set derivative time to 0 sec and

integral time 6000 sec, which will cut off the derivative action and widen the effect of

integral action.

Set the set point to desired level value (@50%). Allow the process to reach at steady state.

17-04-2017

49

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Record the steady state error.

Switch the controller to manual mode. Reduce the integral time to half of the previous

value. Switch to Auto mode and apply step change(+/- 10%) to the set point. Note the

response of the system.

Repeat above step to observe the effect of changes in Integral setting.

Observations

Observe the effect of reducing integral time on the response of the process.

17-04-2017

50

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

5. Aim of the Experiment:-

Study of proportional derivative controller

Apparatus Required:-

Level control trainer

Theory: - Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select PD Mode and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click on

Auto, Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and 100%

Change the controller to Auto mode

Set the proportional band estimated from Proportional control (P only) Set derivative time

to 0 and integral time=6000 sec.

Set the set point to desired value. Allow the process to reach at steady state. Note the

response of the system.

17-04-2017

51

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Switch the controller to manual mode Increase the derivative time by 1 sec. Switch to Auto

mode and apply step change to the set point by 5 to 10%. Note the response of the system.

Increase the derivative time gradually and observe the process response for step change.

Observations

Compare the steady state response of the PD controller with PI controller obtained in the

previous experiment.

17-04-2017

52

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

6. Aim of the experiment:-

Study of proportional integral derivative controller

Apparatus Required:-

Level control Trainer

Theory: - Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select PID mode and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click on

Auto, Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and 100%

Change the controller to Auto mode

Switch the controller to manual mode.

Change the proportional band to the value that estimated in proportional controller. Set

integral time and derivative time based on the responses in previous experiments.

Adjust the set point to @ 50 %. Switch the controller to auto mode. Apply step change of

17-04-2017

53

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

10%. Observe the process response.

Change the proportional band, integral time, derivative time and observe the response of

the process for step change for each change in setting.

Observations:-

Compare the steady state response of the PID controller with P. PI and PD controller

obtained in the above experiment.

17-04-2017

54

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

7. Aim of the Experiment:-

Tuning of controller (Open loop method)

Apparatus Required:-

Level control trainer

Theory: - Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select Process Reaction and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click on

Auto, Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and 100%

Change the controller to Auto mode

Adjust controller output, so that the process value is maintained at 50%.

Start data logging.

Apply a 20 - 30 % change to controller output. (Open the control valve) Record the step

response. Wait for the steady state.

17-04-2017

55

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Stop data logging.

Plot the step response (Process reaction curve) from stored data. Find out the value of slope

at

the point of inflection and time lag.

Calculate P I D settings for different modes.

Select

close loop,

switch auto manual key to auto mode and then select controller to study.

Set the PID values obtained from the calculations. Apply the step change & observe the

response of the system. Allow the system to reach steady state.

Observations

(Refer Theory process control for formulae.)

Step

chan

g

e

t

o

the

s

y

stem

P

=

In

itial

o

u

tpu

t

-

Fi

n

al

o

u

tpu

t

o

f

the

c

o

n

tr

o

ll

er.

Plot the graph of process value Vs Time on a graph paper.rom process reaction curve:

Slope of the process reaction curve R =

Time lag L=

Calculate P, PI, and PID setting from above values.

Observe response of the system for different PID settings.

17-04-2017

56

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

8. Aim of the experiment:-

Tuning of controller (Closed loop method)

Apparatus Required:-

Level control Trainer

Theory: -

Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up

set up as explained in general instructions.

Click Select Experiment, select Close Loop and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click on

Auto, Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and 100%

Change the controller to Auto mode

Select P controller only. Set the proportional band value to maximum (Say 100). Set the

controller to manual mode and adjust the output so that the process value reaches to 50%.

Switch the controller to auto mode and decrease the proportional band and apply the step

change to the set point and observe the process response.

17-04-2017

57

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Repeat the above procedure and find out correct value of proportional band for which the

system just goes unstable i.e. continuous oscillations are observed in the output of

controller.

Record the ultimate proportional band and ultimate period from the response.

Calculate the PID values from the table. Select the PID controller and apply the parameter

values obtained from the above steps. Observe the response of the process to a step change

with these settings.

Observations

Record the ultimate proportional band (

Pbu

) and ultimate period (

Tu

) from above

experiment.

Calculate PID values by referring theory part for different control actions.bserve the process

response for these settings.

Compare the values obtained with open loop response method.

17-04-2017

58

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

9. Aim of the experiment:-

Tuning of controller (Using Auto Tuning method)

Apparatus Required:-

Level Control Trainer

Theory: - Level control trainer is designed for understanding the basic principles of level

control. The process setup consists of supply water tank fitted with pump for water

circulation. The level transmitter used for level sensing is fitted on transparent process tank.

The process parameter (level) is controlled by microprocessor based digital indicating

controller which manipulates

pneumatic control valve through I/P converter. A pneumatic

control valve adjusts the water flow

in to the tank. These units along with necessary piping are

fitted on support housing designed for tabletop mounting.

The controller can be connected to computer through Ethernet

/

USB port for monitoring the

process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select Auto tune and click Start

Wait Till Auto tune is complete. (Blinking of green LED stops).

Controller automatically finds the PB, IT & DT values.

Find out PID values at different set points /flow rates

17-04-2017

59

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Observations

The controller has preprogrammed logic for finding “Auto tune” values. Based on the

response of the process the controller calculates PID values or comes out without finding the

“Auto tune” values.

17-04-2017

60

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Level Controller

Set Point

I/P Converter

Air Regulator

Air Supply

Process Tank

Rotameter

Supply Pressure

Signal

Pressure

LT

Outlet Valve

Pump

Control Valve

10. Aim of the Experiment:-

To study stability of the system (Bode plot)

Apparatus required:-

Level Control Trainer

Theory: - Level control trainer is designed for understanding the basic principles of

level control. The process setup consists of supply water tank fitted with pump for

water circulation. The level transmitter used for level sensing is fitted on transparent

process tank. The process parameter (level) is controlled by microprocessor based

digital indicating controller which manipulates

pneumatic control valve through I/P

converter. A pneumatic control valve adjusts the water flow

in to the tank. These units

along with necessary piping are fitted on support housing designed for tabletop

mounting.

The controller can be connected to computer through Ethernet

/

USB port for

monitoring the process in SCADA mode.

Procedure:-

Start up set up as explained in general instructions.

Click Select Experiment, select Stability analysis and click Start

Open the control valve fully by decreasing the controller output to 0%. (Click

on Auto, Change it to Man then change OP to 0%)

Adjust the tank drain valve such that the tank level shall remain between 90 and

100%

Change the controller to Auto mode

Start data logging.

Select function generator to apply the sinusoidal input to the output of the controller.

17-04-2017

61

Im314A

Department of Chemical Engineering, Veer Surendra Sai University of Technology Burla

Enter Reference point, Amplitude and Period.

Observe the sinusoidal output of the controller and sinusoidal response of the process.

Log the data for records.

Change the period and repeat the observation for 3-4 different values of the period.

Repeat above procedure for different amplitude and period values.

Observations

From the data file stored observe the output response of the process and note

down the output amplitude.

Measure output wave period and note down as T sec. Measure the phase lag x and

note

down in sec.