A Case Study of the STS Indirect and

Support Costs

Lessons to be Learned for the Next Generation Launch System

Zachary C. Krevor

AE 8900 Special Project

April 23, 2004

School of Aerospace Engineering

Space System Design Laboratory

Georgia Institute of Technology

Atlanta, Georgia 30332-0150

Advisor: Dr. John R. Olds

TABLE OF CONTENTS

LIST OF FIGURES........................................................................................................III

LIST OF TABLES............................................................................................................V

ACRONYMS AND SYMBOLS.....................................................................................VI

1.0 RESEARCH GOAL ................................................................................................... 1

2.0 INTRODUCTION ...................................................................................................... 3

3.0 STS BACKGROUND................................................................................................. 5

4.0 NASA SHUTTLE RESPONSIBILITIES............................................................... 10

4.1 FIELD CENTER ROLES IN THE STS PROGRAM........................................................... 10

4.2 JSC AS LEAD STS CENTER ....................................................................................... 13

4.3 MISSION CONTROL CENTER DEVELOPMENT ............................................................ 18

5.0 STS CONTRACTORS ............................................................................................. 20

5.1 CONTRACTOR USE IN MANNED SPACEFLIGHT HISTORY .......................................... 20

5.2 THE STS CONTRACTORS.......................................................................................... 24

5.3 UNITED SPACE ALLIANCE........................................................................................ 29

5.4 CURRENT PRIME CONTRACTOR BREAKDOWN.......................................................... 30

6.0 BREAKDOWN OF 1994 SHUTTLE COSTS........................................................ 32

6.1 SYSTEMS MANAGEMENT, OPERATIONS AND PLANNING .......................................... 33

6.2 CONCEPT-UNIQUE LOGISTICS .................................................................................. 37

6.3 OPERATIONS SUPPORT INFRASTRUCTURE ................................................................ 39

6.4 TRAFFIC AND FLIGHT CONTROL............................................................................... 41

6.5 VEHICLE DEPOT MAINTENANCE .............................................................................. 43

7.0 ANALYSIS AND IMPROVEMENT IDEAS FOR THE STS PROGRAM........ 46

7.1 SYSTEMS MANAGEMENT RESTRUCTURING.............................................................. 46

7.2 REDUCING COSTS IN THE CONCEPT-UNIQUE SYSTEMS AREA .................................. 53

7.3 OTHER AREAS FOR COSTS REDUCTION.................................................................... 57

7.4 COMPLETE STS PRIVATIZATION .............................................................................. 60

7.5 TOTAL COST SAVINGS ............................................................................................. 63

8.0 FUTURE DESIGN RECOMMENDATIONS........................................................ 65

8.1 A FUTURE LAUNCH VEHICLE SYSTEM ..................................................................... 67

9.0 CONCLUSIONS AND FUTURE WORK.............................................................. 70

9.1 CONCLUSIONS.......................................................................................................... 70

9.2 FUTURE WORK......................................................................................................... 73

10.0 REFERENCES........................................................................................................ 76

APPENDIX A: STS 1994 WORKFORCE BREAKDOWN

18

.................................... 79

APPENDIX B: STS WORKFORCE BREAKDOWN FROM 1993-2003

8

............... 91

APPENDIX C: SECOND-LEVEL DSM..................................................................... 91

APPENDIX D: ENDNOTES......................................................................................... 92

ii

List of Figures

Figure 1: Iceberg Analogy for STS Program..................................................................... 2

Figure 2: Rockwell Resuable Shuttle Design. ................................................................... 7

Figure 3: Rockwell Early External Tank Configuration.................................................... 8

Figure 4: Rockwell's Final Shuttle Design. ....................................................................... 9

Figure 5: NASA Installations and Prime Contractor Locations. ..................................... 10

Figure 6: STS at KSC Launch Complex.......................................................................... 11

Figure 7: Marshall Space Flight Center in Huntsville, AL.............................................. 12

Figure 8: SSC SSME Test Bed........................................................................................ 12

Figure 9: Original Area for JSC Development................................................................ 15

Figure 10: Aerial View of JSC......................................................................................... 16

Figure 11: MCC at JSC.................................................................................................... 19

Figure 12: Mercury Capsule delivered by McDonnell.................................................... 21

Figure 13: Gemini Spacecraft.......................................................................................... 22

Figure 14: Apollo Contractors and Physical Locations................................................... 24

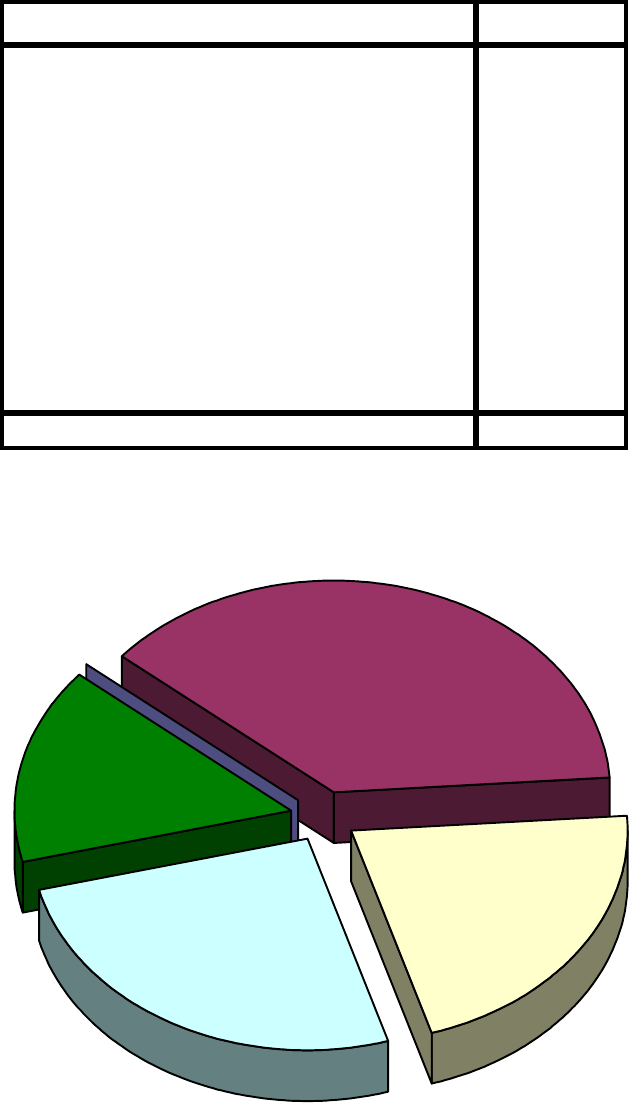

Figure 15: 1994 STS Contractor Percentage Breakdowns.

14

........................................... 26

Figure 16: Thiokol SRB Testing...................................................................................... 26

Figure 17: Dan Goldin announcing USA's Partnership with NASA............................... 29

Figure 18: Current STS Breakdown. ............................................................................... 31

Figure 19: Systems Management Area broken into Sub-Functions. ............................... 34

Figure 20: Concept-Unique Breakdown Percentages...................................................... 38

Figure 21: Percentage Breakdown of Operations Support Infrastructure Cost. .............. 40

Figure 22: Percentage Breakdown of Traffic and Flight Control.................................... 42

Figure 23: Vehicle Depot Percentage Breakdown........................................................... 44

Figure 24: STS Program Management. ........................................................................... 47

Figure 25: STS Management DSM.................................................................................. 49

Figure 26: Proposed STS Management Structure............................................................ 50

Figure 27: New Management DSM................................................................................. 52

Figure 28: STS Program Hardware Flow. ....................................................................... 54

Figure 29: Shuttle at the Palmdale Facility...................................................................... 59

iii

Figure 30: Monte Carlo Simulation for Cost Savings. .................................................... 64

Figure 31: Delta IV Heavy Preparing to be Loaded Vertically onto the Launch Pad. .... 67

Figure 32: Shuttle Undergoing Routine Processing in the OPF. ..................................... 69

Figure 33: Summary of Indirect Cost Region Reduction ................................................ 71

iv

List of Tables

Table 1: 1994 Prime Contractor Breakdowns.................................................................. 25

Table 2: Systems Management Breakdown..................................................................... 34

Table 3: Breakdown of Program Management and NASA Institution Employees......... 35

Table 4: Launch and Landing Sub-Areas. ....................................................................... 36

Table 5: Mission Operations Sub-Area............................................................................ 36

Table 6: Concept-Unique Logistics Cost Breakdown. .................................................... 37

Table 7: Major Employee Areas of Concept-Unique Logistics Section.......................... 38

Table 8: Breakdown of Operations Support Infrastructure Cost..................................... 40

Table 9: Largest Employee Regions within Launch and Landing Operations................ 41

Table 10: Cost Breakdown of Traffic and Flight Control................................................ 42

Table 11: Vehicle Depot Maintenance Cost Breakdown................................................. 43

Table 12: Summary of Indirect Costs by category in $M FY 1994................................. 45

Table 13: Indirect Cost Summary broken down into Employee Numbers...................... 45

Table 14: Input Distributions for Monte Carlo Simulation ............................................. 64

Table 15: Statistics from the Monte Carlo Simulation .................................................... 64

v

Acronyms and Symbols

ARC Ames Research Center

CA Contributing Analyses

CEV Crew Exploration Vehicle

COTS Commercial Off the Shelf

DOD Department of Defense

ET External Tank

EVA Extravehicular Activity

FY Fiscal Year

GAO General Accounting Office

GEAE General Electric Aircraft Engines

GFE Ground Furnished Equipment

GSE Ground Support Equipment

GSFC Goddard Space Flight Center

HRST Highly Reusable Space Transportation

ISS International Space Station

JSC Johnson Space Center

KSC Kennedy Space Center

LCC Life Cycle Cost

LEO Low Earth Orbit

LEM Lunar Excursion Module

LaRC Langley Research Center

LRU Line Replacement Unit

MAF Michoud Assembly Facility

MCC Mission Control Center

MOD Mission Operations Directorate

MSC Manned Spacecraft Center

MSFC Marshall Space Flight Center

NAA North American Aviation

vi

NASA National Aeronautics and Space Administration

OMB Office of Management and Budget

OMS Orbital Maneuvering System

OPF Orbiter Processing Facility

P & W Pratt and Whitney

RCS Reaction Control System

RFP Request for Proposal

SFOC Space Flight Operations Contract

SRB Solid Rocket Booster

SRM Solid Rocket Motor

S R & QA Safety, Reliability and Quality Assurance

SSC Stennis Space Center

SSMEs Space Shuttle Main Engines

STG Space Task Group

STS Space Transportation System

STSOC Space Transportation System Operations Contract

TPS Thermal Protection System

VAB Vehicle Assembly Building

vii

1.0 Research Goal

On January 14, 2004, President George W. Bush laid out an ambitious plan to

return the United States to the moon. Additionally, he set a course for the future human

exploration of the planet Mars. These plans give the National Aeronautics and Space

Administration (NASA) a clear mission for its future. Within NASA’s new initiative,

plans were made to retire the current United States human launch vehicle. The current

United States human launch vehicle, the Space Transportation System (STS), was not

built to explore any region beyond a Low Earth Orbit (LEO). Therefore, to complete this

exciting program, a new launch vehicle system for manned exploration must be

developed. The STS program has provided a wealth of information for human launch

systems. Knowledge gained from all areas of the STS program must be applied in

developing the new human launch system.

For the new space initiative, the cost of the program will be one of the biggest

influencing factors upon whether or not the mission plan is carried out. If the costs are

deemed too high, the public and the current political climate will kill the initiative.

Therefore, in order to achieve this stirring goal of planetary exploration, costs must be

factored into every design decision. The effects of a design choice must not only be

considered for the development cost, but also for effects on Life Cycle Cost (LCC). This

includes any new launch vehicle system that may be developed.

In order to achieve the new initiative, access to space must become cheaper. The

current STS program uses approximately one-third of NASA’s available budget. In

1994, the year for which the most detailed cost data is available, the STS program budget

was over $3.3 billion dollars (FY 1994)

1

. However, approximately 90% of these costs

went to indirect and support costs. These areas include program management, logistics

sections, and support groups for a wide range of work within the program. The direct

operations aspect of the STS program has been studied in great detail. However, these

indirect costs have not been examined, and therefore potential savings may exist within

these areas. Also, investigating the indirect costs of the STS program will result in

important knowledge about how to reduce these costs for the next generation launch

1

system. The lessons learned from this examination will show how far various design

choices go towards influencing LCC.

The main goal of this project is to examine the indirect costs of the STS program

for cost savings. A more detailed examination of these indirect costs will lead to areas

where inefficiency in the program is occurring. Additionally, another goal of this project

is to show how design decisions greatly impact the LCC. In the short term, these choices

may have aided vehicle performance, but they ended up costing the program more to

perform its mission. Another goal of this project is to use the knowledge gained from

examining the indirect and support costs to help influence the next generation launch

vehicle. It is imperative that costs for this program are kept as low as possible, without

compromising safety, in order to achieve the new space exploration initiative.

The inspiration for this project came directly from the work completed by Mr.

Edgar Zapata and Mr. Carey McClesky at NASA KSC. They have provided the budget

charts for which the main crux of this project is based upon. Figure 1 is the iceberg chart,

describing the analogy between an iceberg and the shuttle program. Most of the structure

of the iceberg is below water, while most of the shuttle program costs are below the

support line. It has been said that for every person working directly on the shuttle, there

are between 7 and 10 more employees supporting him or her.

Figure 1: Iceberg Analogy for STS Program.

Direct (Visible) Work

<10%

“Tip of the Iceberg”

+

~20%

Indirect (Hidden)

Support (Hidden)

+

~70%

Recurrin

g

O

p

s

$$

s

Generic

Operations Function

Total

$M

FY94

Total

(%)

Elem. Receipt & Accept. 1.4

0.04%

Landing/Recovery 19.6

0.58%

Veh Assy & Integ 27.1

0.81%

Launch 56.8

1.69%

Offline Payload/Crew 75.9

2.26%

Turnaround 107.3

3.19%

Vehicle Depot Maint. 139.0

4.14%

Traffic/Flight Control 199.4

5.93%

Operations Support Infra 360.5

10.73%

Concept-Uniq Logistics 886.4

26.38%

Trans Sys Ops Plan'g & Mgmnt 1487.0

44.25%

Total ($M FY94) 3360.4 100.00%

STS Budget "Pyramid"

(FY 1994 Access to Space Study)

2

2.0 Introduction

The space shuttle program has been the launch vehicle for manned systems in the

United States for the last 20 years. Throughout the shuttle’s history, it has undergone

many fluctuations in budget, various re-structuring efforts, and constant upgrades. The

program has also seen large fluctuations in its workforce. These oscillations in the

program are a result of the technical challenge of launching humans into space; this task

has proved to be a very complex problem.

This paper will first look at the background of the STS program. The shuttle

design will be examined to show how certain design choices resulted in its high LCC.

Additionally, the role of each NASA center will be considered to show the complexity of

the total launch vehicle system. By scrutinizing the role of each NASA field office,

possible savings may be realized because of duplicity of roles and responsibilities.

Finally, the choice of Johnson Space Center (JSC) as both the lead center for the shuttle

program, and for mission control will be looked at to determine its effect upon the

program LCC.

The next section of this paper will examine the contractor role within the STS

program. The program uses many different contractors. While the main hardware

contractors have stayed constant, with some slight changes, big changes throughout the

program have been made in the area of operations. In using so many different

contractors, there exists the possibility of overlap. This project will further detail the

contractor involvement in the STS program, and reveal some areas where cost savings

can be created. Additionally, future recommendations for the next launch system will be

made based upon how contractors impact the current launch vehicle system.

By detailing the indirect and support costs, important information can be gleaned

about how program decisions affect LCC. Five main areas have been identified within

the STS program that are counted as indirect and support costs. Those five areas are:

• Systems Management, Operations and Planning

• Concept-Unique Logistics

• Operations Support Infrastructure

• Traffic and Flight Control

• Vehicle Depot Maintenance

3

This project will inspect these areas inside the STS program. In some areas there are

inefficiencies occurring that could probably be reduced. These improvements would help

with the LCC. In other areas, initial design choices for the STS program led to costs that

cannot be reduced. Yet, with the program being retired by 2010, it is imperative to use

all of the knowledge gained from examining these indirect costs for use in the next

launch vehicle.

After suggesting improvements to reduce the indirect and support costs,

recommendations will be made for future systems. These recommendations will

hopefully aid future launch vehicle decisions. Historical trends will be examined to

reveal more trends in the indirect and support costs. Finally, possible deviations from the

historical method of accomplishing space access will be discussed. There areas include

possible ideas such as the complete privatization of launch services, with NASA as

strictly oversight organization. Different management ideas will be introduced and a

different methodology for designing the next generation launch vehicle will be discussed.

The lessons learned from reviewing the indirect costs must be applied for future

launch vehicle systems. The LCC of the program must be kept to a minimum in order to

go back to the moon and beyond. To achieve this, the indirect and support costs must be

reduced. NASA cannot afford to have its launch vehicle system use one-third of its

budget on the way to further space exploration. Additionally, any potential next

generation launch system cannot afford to have its indirect and support costs using ninety

percent of the available budget. This paper will show where the indirect and support

costs are occurring, what can be done to reduce them, and how the knowledge of these

costs must be used for recommendations with the future launch system.

4

3.0 STS Background

In the late 1960s, even with the Apollo project in full swing, the NASA

administration began to look towards the future. The success of the Apollo project, and

the public support that NASA enjoyed led the administration to dream large. In 1969, the

NASA administrator, Thomas Paine, met with then President Richard Nixon to push the

expansion of the space frontiers. Paine envisioned a future with an orbiting space station

for use as a stopover on the way to both lunar and Martian base stations

2

. The vehicle to

accomplish these missions would be NASA’s new, fully reusable space shuttle.

The Saturn launch vehicle was developed and used by the Apollo program. While

this launch vehicle accomplished its mission with a high rate of success, the cost per

launch was very expensive. Each Saturn launch cost $185M in 1970; this translates to a

staggering cost of $734M

3

(FY 2004) in today’s economy. Additionally, the Saturn was

an expendable vehicle, and a new one was used for each Apollo launch. Many advocates

of a reusable space program claimed this was akin to flying on a new airplane and

throwing it away after each flight. Therefore, NASA decided that a new vehicle, fully

reusable, would usher in the post-Apollo era.

Unfortunately, the decade of the 1970s was a turbulent one. The Vietnam War

was dividing the country, inflation was soaring, and space began to fade from the public

eye. Under budget constraints, the Office of Management and Budget (OMB) cut

NASA’s budget request by $1B (FY’ 70). Plans for exploration bases immediately

halted, and concentration was placed on a space station and the shuttle. As the budget

reduced further, a transition began towards simplifying the shuttle design. Additionally,

the increase of inflation caused NASA to choose between the space station and the

shuttle. Since the space station could not be created without the shuttle, the space station

program was put on hold. The shuttle program became the main thrust of NASA’s effort.

The final orbiter design was created through the combination of NASA needs

and the Air Force influence. NASA justified this system with economic estimates that it

could capture the launch vehicle market using the shuttle. Initial estimates put the cost

per shuttle launch at approximately $10M (FY 1970)

2

. Since current expendables then

cost $12M, the shuttle would be used on virtually all space launches. Initially, the shuttle

5

program was on the verge of being deemed to expensive. The OMB looked to cut the

shuttle program entirely in 1971, and it was only with the aid of the Air Force that the

shuttle program stayed. NASA appealed to the Air Force for support; in exchange, the

Air Force would be able to help shape the design requirements. NASA convinced the Air

Force that it could complete all future launches using the NASA vehicle. The Air Force

had been having its own problems getting its space programs funded, and recognized that

the shuttle could greatly aid their agenda. With the Air Force’s support the shuttle

requirements began to take shape. The Air Force wanted to be able to launch large

military satellites into a polar orbit. These satellites could weigh upwards of 40,000

pounds. This requirement translated into a 65,000 pound requirement to LEO on a due

East inclination launch. The payload bay would also have to be very large in order to

accommodate such large satellites. Additionally, the Air Force wanted the shuttle to have

abort capability after a single orbit, and the ability to land back at its launch site; thus, a

large cross range requirement was imposed

4

. With the polar orbit requirement, a cross

range of 1,000 miles was needed in order to land back at Vandenberg. The orbiter now

needed a higher lift to drag ratio than previously designed, and would require greater

thermal protection, which led to heavier wings. With the shuttle weight beginning to

grow, the boosters also had to grow in size and capability.

Various different shuttle designs were considered. Initial designs from Lockheed

included a two-stage, fully reusable shuttle built with all aluminum. With the Air Force

influencing the shuttle program, it further recommended the use of aluminum. The Air

Force had performed a study that showed the current aerospace industry did not have the

tooling needed to fabricate large structures from titanium

. NASA and contractors further

studied the titanium versus aluminum consideration. These trade studies showed that a

titanium shuttle would weigh 15% less than its aluminum counterpart. Titanium could

withstand an additional 350°F, and would save in the amount of thermal protection

required, in addition to being a lighter material. Yet, titanium carried a greater

development risk, and therefore a greater development cost. The full revolution of LCC,

and quality from initial design had not yet begun to take root in the United States. The

focus during this period of design was on keeping the development costs down. Thus,

aluminum was used for the shuttle structure. Many future decisions were also made with

6

low development cost in mind; these decisions would have large impacts on the later

phases of the shuttle program.

A new engine had to be developed to meet the requirements of the space shuttle;

this engine would become the Space Shuttle Main Engine (SSME). The experience of

using liquid hydrogen and liquid oxygen engines to achieve higher Isp levels led to a

preference for this fuel. NASA designers wanted an engine to produce 415,000 pounds

of thrust, and the Saturn J-2 could only provide 230,000 pounds of thrust. Pratt and

Whitney (P & W), plus Rocketdyne emerged as the two competitors for this contract. P

& W had working for many years on developing high performance liquid hydrogen and

liquid oxygen engines. While P & W focused on developing the turbopumps,

Rocketdyne decided to run tests that would demonstrate other features of the SSME

design by building a complete thrust chamber: this included the required thrust levels,

stable combustion, and the proper chamber pressure

. NASA designers then increased the

desired thrust to 550,000 pounds to match an increased payload capacity. Rocketdyne

demonstrated an initial superior product, since its thrust levels reached 505,000 pounds

while P & W only went to 350,000 pounds. Rocketdyne was eventually awarded the

contract, although there was a contentious battle fought through auditors that concluded

NASA had made a sound decision.

Figure 2: Rockwell Resuable Shuttle Design.

The initial 1

st

stage booster concepts for the shuttle were large winged vehicles

that would fly back to Earth. Rockwell’s initial design used 12 SSMEs’, and 12 jet

engines for use during flyback

. However, under the tightening budget due to OMB cuts,

7

the program could no longer fund a completely reusable vehicle. Again, an emphasis in

the United States on LCC was nowhere near the levels where it is now; thus, the

emphasis was placed on the development cost of the shuttle. Lockheed Martin had

already been working on a partially reusable concept. This design would carry the

hydrogen in an expendable, external tank. This tank could be aluminum, and would burn

up upon entry. The development costs would be reduced, and the orbiter no longer had to

carry the bulky hydrogen inside its structure. Additionally, the orbiter weight would be

reduced since the hydrogen tanks no longer needed to be thermally protected to the levels

required by re-entry. After reviewing this idea, NASA immediately directed Rockwell

and McDonnell Douglas, who were also competing for the prime shuttle contract, to

consider storing the liquid hydrogen in expendable tanks

. The next progression was to

realize that the oxygen fuel should also be stored in the expendable tank. Now the orbiter

could be smaller and independent of the external tank designs, except for the structural

interfaces. With a smaller orbiter, the staging point could occur lower in the trajectory,

which would reduce the booster requirement, which would reduce the development cost.

Figure 3: Rockwell Early External Tank Configuration.

While the external tank (ET) was taking shape, a debate was occurring over how

to accomplish finishing the booster stage. Martin Marietta began to push its Titan rocket

concept, where six solid rocket boosters would surround the external tank. Thiokol,

Aerojet, and United Technology were pushing their own solid rocket booster designs.

The NASA Marshall Space Flight Center entered with a desire for pressure-fed liquid

8

boosters surrounding the core

. However, the OMB continued to press NASA for

lowering development costs, and therefore the solid booster design was chosen

. The Air

Force had experience in building large solid rocket motors with their work on the Titan

III, and this further convinced the OMB that NASA should use solid boosters.

Additionally, NASA conceded that some boosters may be lost at sea, and solids would be

cheaper to replace. Therefore, the OMB appropriated NASA’s shuttle development

accordingly for this option

.

Once NASA had decided upon the design of the STS, requests for proposals

(RFPs) went out on March 17, 1972. Four companies responded: Rockwell, McDonnell

Douglas, Lockheed and Grumman. Lockheed had no experience with building piloted

spacecraft, and their proposal for the orbiter was heavier than the other three.

Additionally, Lockheed’s orbiter would cost $40M (FY ’72) more than Rockwell’s

shuttle design

. While McDonnell Douglas had built the Mercury and Gemini spacecraft,

their review went poorly

. They answered questions with vague, general answers, and did

not leave NASA’s shuttle review team with a good impression

. Grumman and Rockwell

had worked together on building the maneuvering portion of Apollo. Yet, Rockwell won

the proposal due to a lower orbiter dry weight and a lower development cost. Rockwell’s

proposal included the least amount of “man-years” for the shuttle program, and NASA

administration officials recognized that this is where true savings would be realized

.

Rockwell was contracted for the STS program.

Figure 4: Rockwell's Final Shuttle Design.

9

4.0 NASA Shuttle Responsibilities

The STS program is split over many different parts of the United States. Six

different field centers have some direct contribution to the shuttle program. Several other

field centers and Department of Defense (DOD) facilities make contributions.

Additionally, many private contractors work in the STS program. This section will

explore the responsibilities of each field center, and examine why Johnson Space Center

(JSC) was chosen as both the lead center for Shuttle, and the site for mission control.

4.1 Field Center Roles in the STS Program

NASA headquarters, which is located in Washington D.C., controls the various

space flight centers and installations that constitute the total NASA program. It has

responsibility for determining projects and their direction. Headquarters also shapes

NASA policy decisions. They perform design reviews and evaluate the progress of all

programs across NASA. Finally, the establishment of management structure, procedures

and performance criteria are all completed at Headquarters. The STS program is one

program that is monitored directly by this office

5

.

Figure 5: NASA Installations and Prime Contractor Locations.

10

JSC, located in Houston, Texas, is the lead center for the STS program and the

program office for the STS resides here. JSC is NASA’s main center for the design,

development and testing of manned spacecraft systems. This center had a principal role

in the shuttle design: this included the orbiter, payload integration and overall STS

program integration. This center is currently “responsible for operational planning,

astronaut selection, crew and console operator training, flight control, and control of

experiments and payload aboard

” the STS. The mission control center (MCC) at JSC

runs the flight operations for the shuttle immediately after launch and until landing is

completed. JSC also runs the White Sands testing facility, which is responsible for the

hypergol propulsion testing.

Kennedy Space Center (KSC), located at Cape Canaveral, FL, is the launching

pad for STS missions. KSC was developed in the late 1950s with the specific goal of

launching manned spacecraft. Currently, it is the home to the shuttle fleet: Atlantis,

Endeavor, and Discovery. KSC is the primary NASA center for test, checkout and

launch of manned space vehicles. This center handles the post-processing of the shuttle

once it has safely landed. All shuttle logistics, including items such as propellant storage,

happen at KSC. Also, KSC operates the facilities which are used for mating the orbiter to

the external tank (ET) and the solid rocket boosters (SRB).

Figure 6: STS at KSC Launch Complex.

Marshall Space Flight Center (MSFC), located in Huntsville, Alabama, is in

charge of the propulsion aspects of the STS system. This center is known as “rocket

11

city” due to its role in developing launch vehicles for use by NASA. Wernher von Braun,

one of the pioneers of rocketry, was at one time director of this center. MSFC has the

principal role for providing the ET, the SSMEs, and the SRBs. MSFC operates the

Michoud Assembly Facility (MAF) where the ETs’ are manufactured. This center also

has a key role in the development of shuttle payloads. This includes Spacelab, which is a

reusable “modular scientific research facility carried in the Shuttle cargo bay”

5

.

Figure 7: Marshall Space Flight Center in Huntsville, AL.

Stennis Space Center (SSC), located near Bay St. Louis, Mississippi, is

responsible for SSME and other orbiter propulsion testing. Its large test beds were used

for developing the SSME, and continued to be used for developing upgrades. These test

beds can accommodate full SSME testing and thus provide an important service to the

STS program.

Figure 8: SSC SSME Test Bed.

12

Another NASA center that provides support for the STS program is the Goddard

Space Flight Center (GSFC), in Greenbelt, Maryland. This is the primary facility for

tracking and communicating with the Shuttle. Goddard is in charge of maintaining

relations with the various tracking stations around the world that are used during a shuttle

mission. GSFC also operates the Wallops Flight Facility, which is a small launching pad

that performs a variety of research missions.

Both the Ames Research Center (ARC), located near San Jose, California, and

the Langley Research Center (LaRC), provide support for the STS program. ARC

provides support through wind tunnel testing and thermal protection system development.

LaRC is the primary research facility for structures and materials. It is at LaRC that the

landing gear for the shuttle is tested. In addition, LaRC also performs

aerothermodynamics analysis for space vehicles and preliminary aerodynamics research.

The DOD is another agency that provides support for the STS program. This

support is provided by the “Air Force Space Division” located in California

. This

division would be the primary “contingency support for the Space Shuttle in the event of

an emergency landing”. Additionally, the Space division designed a second launch

complex at Vandenberg Air Force Base in California. Initially begun in 1966, but

canceled three years later due to cost overruns, this shuttle complex never developed into

the launch site foreseen by the Air Force. In 1979, $4B was injected to finish

development, but following the Challenger accident, NASA and the Air Force decided to

consolidate and focus launch operations solely at Cape Canaveral.

4.2 JSC as lead STS center

JSC has held the title of lead center for the STS program for virtually all of the

program’s lifetime. A break did occur after the Challenger accident, which will be

discussed later, but JSC was eventually restored to lead status once again. Using this lead

center style of management has wide ranging effects upon the STS program. There has

been debate within NASA about whether the lead center arrangement is the most optimal

for managing a large program. However, the tradition of lead center management dates

all the way back to NASA’s predecessor, the National Advisory Committee for

Aeronautics (NACA)

6

. LaRC was typically the research lead in cross center projects,

13

while Lewis Research Center and ARC took more of a secondary role. Thus, a precedent

had been set to which the NASA administration was accustomed.

JSC was created in 1961 as the Manned Spacecraft Center (MSC). This was to be

the new home for the Space Task Group (STG), which was the precursor to the official

human spaceflight program at NASA. This group was initially formed at Langley in

conjunction with the formation of NASA, which was a direct response to the Soviet

launch of the satellite Sputnik. The United States administration could not believe that

the country was now second to the USSR in terms of space technology. The U.S. also

feared what kind of military capabilities the USSR might also be able to launch in space.

Thus, NASA was created, and charged with the future of the U.S. space program. Once

NASA began officially functioning on October 1, 1958, one of the first orders of business

was to organize the Space Task Group.

This group was formed at Langley, and initially did not have a good course of

action. The public and many officials in government did not believe that the American

response to Sputnik should be to put an “American in space”

. However, under the

effective leadership of former President Lyndon B. Johnson (for whom the Houston

facility is named after), who was a senator at the time, the public and government was

quickly convinced of the necessity for human space travel. During this period, the STG

immediately began to come up with ideas for a manned launch. The group went to meet

with Wernher von Braun and his associates at MSFC to discuss this plan further. After

consulting with von Braun and his team of engineers, the preliminary designs for what

would later become the Mercury project were completed. NASA administration quickly

realized that the STG would need a new home.

While operating at LaRC, the STG reported directly to NASA headquarters

.

Some within LaRC wanted to keep the STG at LaRC, but make them operate within the

center. NASA administrator James Webb believed that STG should be its own entity and

thus began a study of where this group should work. Friction had begun between STG

and other researchers at LaRC due to the fact that STG did not report directly to LaRC

management. GSFC initially believed that they should receive the new group, but this

transfer was quickly ruled out due to a lack of facilities. Others in the NASA

administration believed that ARC should be the new home of STG

. This would provide

14

better contact with the eventual contractors for Mercury, and provide an easy way for

both NASA and the contractors to help create the Mercury project. Webb eventually

decided that a new facility should be created for this group. A task force was created to

study possible sites for the new MSC. The initial location that was chosen was Tampa,

Florida

. The conditions for choosing a site included both flight test facilities, and large

tracts of land. Tampa had both, with an Air Force base that was due to close. However,

two months after the study was completed, but before a final decision had been made, the

Air Force decided to keep the base in Tampa open. The second choice for the MSC was

Houston, Texas. Houston also had an Air Force base, Ellington, but this base had not

been used since World War II

. Additionally, Rice University immediately recognized the

benefits of having a science organization in their “backyard”, and agreed to donate 1,000

acres of land

. Finally, whether or not political pressure was truly applied, it definitely

helped Texas that Senator Johnson, leading the charge for human space exploration, was

also from Texas. The Representative in charge of Appropriations, and therefore NASA’s

“purse”, was from the Houston district. All of these factors led to the creation of the

MSC in Houston, Texas.

Figure 9: Original Area for JSC Development.

7

While the MSC was being constructed, STG remained the lead center for the

Mercury program. After the facilities were constructed, the center immediately became

the lead for the Gemini, and Apollo missions. Development on these last two programs

had begun before the finish of construction at MSC due to the push by President John F.

Kennedy, who further defined NASA’s mission when he declared that the United States

15

would be headed to the Moon. All three manned programs operated out of JSC. Thus,

when time came for the development of the STS program, it seemed only natural that JSC

remain as the lead center. Headquarters also designated JSC as the lead for negotiations

with the contractors, which further entrenched JSC in this role. Finally, the American

public had become used to the astronauts as the face of NASA. The astronauts operated

out of JSC, and thus the public viewed this facility as the proper center of manned

spaceflight.

Figure 10: Aerial View of JSC.

As the budget in the 1970s began to dwindle, Headquarters wanted to keep

staffing at their location to a minimum, probably due to the fact they were so visible to

Washington. This further entrenched JSC as the lead center for shuttle operations. The

lead center style of management was thought to be the most effective use of resources in

this budget slashing era. Headquarters would still control the major milestones, but MSC

had direct program management responsibility. Both KSC and MSFC would report to

MSC (which did “rankle” a few employees at MSFC). Integration panels were created

for each center, which all reported to the Systems Integration Office at JSC. MSFC was

designated lead center for developing the propulsion systems, while KSC was in charge

of designing and directing the launch and recovery facilities.

JSC would stay as the lead center for the STS program until the Challenger

accident. It oversaw all the initial launches and successes of the program. However, the

16

Challenger accident led to internal reviews, which revealed flaws within this management

structure. Headquarters took control of the STS program office, and reorganized the STS

structure accordingly. JSC had lost some stature with headquarters and in the public eye

due to the Challenger accident. Furthermore, crew systems and flight capsule

development were transferred to MSFC. This structure was relatively constant until

NASA administrator Dan Goldin shook up the NASA organization with the “faster,

better, cheaper” mantra and style. Goldin, in 1996, decided that JSC should once again

be the lead center for the STS program. In trying to cut costs from NASA’s budget, he

also believed that the lead center management style was the most cost effective for the

STS program. This was part of a general move of all program management

responsibilities to the NASA field centers

8

. Once again JSC would have authority over

the funding and management of Shuttle activities. MSFC did not like the new

arrangement, and others in the administration wondered why the shuttle should return to

the flawed management structure of before. No mishaps had occurred while the STS

program was under the watchful eye of Headquarters, but the transfer was completed

nonetheless.

As will be seen later, the structure of the STS program has many influences upon

the LCC of the program. While some benefits are realized from removing Headquarters

from day to day operations of the Shuttle, a lead center with multiple other

responsibilities outside of the STS program can result in overlap of responsibilities. JSC

is also in charge of the International Space Station (ISS) program and must devote many

of its resources to successful operation of that program. In addition, overlapping

responsibilities can occur within the program if the center roles are not truly defined.

One example is how both JSC and KSC operate flight operations. KSC is in charge of

the launch operations until the shuttle clears the tower; then JSC is responsible for flight

operations until the STS program is on the ground again. Yet, exactly where each of

these centers takes over their role is not completely defined. Obviously, once in orbit,

JSC has complete control of the shuttle; however, both KSC and JSC will monitor launch

and landing operations. The choice of how this occurred, and why JSC was also

designated the site for the MCC is the discussion of the next section.

17

4.3 Mission Control Center Development

For the first manned spaceflight program, the Mercury project, KSC had initial

flight control operation with the flight monitoring systems located at GSFC. The Cape

Canaveral launch facilities, which started with missile development and testing, were

turned over to NASA by President Eisenhower in 1959. During the development of the

Gemini and Apollo programs, the NASA administration quickly realized that a new,

state-of-the-art MCC needed to be built. KSC immediately thought that this should be

built at their site in Florida. They claimed intimate flight operation knowledge because

they were already used to operating the flight controls for project Mercury; although this

operation did not require much after the launch of the spacecraft since Mercury was a

non-maneuvering vehicle. However, communications at the Cape were a source of

controversy and politics. There was an ownership question about who controlled the

current networking existing at the Cape. The DOD insisted that they owned the cabling

inside the fences, while Radio Corporation of America said they carried the cable to the

fence itself. Also, NASA employed three different telephone carriers that could not agree

about how to construct new cable for the Cape. Meanwhile, both Gemini and Apollo

program directors were clamoring that MCC should be at JSC. With MCC at JSC, it

would put the flight controllers in direct contact with the design engineers of each

program. NASA also realized that through the use of new networking technology, they

could build a MCC virtually anywhere. JSC became the choice for a brand new MCC

center. However, with the construction of new facilities for the Saturn launch vehicle at

KSC, a new control center was also built for monitoring launches.

JSC has monitored flight operations since Gemini IV. Other center participation

included KSC who provided backup services for launch and trajectory, and GSFC

continued their involvement with vehicle tracking. The MCC was very busy throughout

the Gemini and Apollo programs, with constant launches and monitoring. With the

advent of the shuttle program, MCC would be the focal point of flight operations for that

vehicle. There was no incentive to adjust, plus the STS program was worried about

keeping itself afloat. However, as will be seen later, the choice of MCC at JSC has led to

overlaps within the STS program that should be evaluated for the next generation launch

vehicle.

18

Figure 11: MCC at JSC.

19

5.0 STS Contractors

Throughout the history of manned space flight, NASA has consistently used the

help of private industry to accomplish its missions. From the project Mercury, to the ISS,

private contractors have had a hand in developing human spaceflight. For the early

projects, NASA engineers had most of the experience due to their research work for

NACA. There was very little turnover in NASA during the early years, and thus a great

deal of expertise existed at the organization. With their hands-on experience through

previous research, NASA engineers were able to effectively manage and guide the

contractors to the final design of the project. The NASA engineers were collaborators

with the private contractors, rather than simply purchasing hardware. This situation

changed as industry gained more experience, and dwindling budgets within NASA

caused greater turnover. By the time of full scale development of the STS program,

NASA had already undergone major personnel changes and losses. The relationship with

contractors moved towards a more traditional role of buying hardware. However, with

program management for STS in NASA hands, NASA engineers still played a major role

in defining the hardware designs. This section will examine the use of contractors

through history, and examine the contractor situation as it has changed for the STS

program.

5.1 Contractor Use in Manned Spaceflight History

For the first human spaceflight, project Mercury, the competition for the prime

contract came down to Grumman Aircraft and McDonnell Aircraft. This was the contract

to build the capsule that the astronauts would fly in. At the time, Grumman had many

Navy projects it was working on that were only in the conceptual phases of their design.

NASA was worried about both scheduling conflicts and the priorities of Grumman, and

awarded the prime contract for the capsules to McDonnell Aircraft. The initial contract

for twelve space capsules was worth $18.3 M (FY ’59), with a fee of $1.15M (FY ’59)

9

.

However, costs quickly spiraled up due to the combination of an optimistically low bid

and more requirements that were added, such as a request for spare parts. Additionally,

each of the capsules delivered was unique and tailored for the specific mission.

20

McDonnell eventually included some 4000 suppliers, 596 direct sub-contractors

from 25 different states, and 1500 second-tier subcontractors. As alluded to earlier,

NASA engineers and McDonnell worked closely together. STG drew up the original

fifty page document for its ideas of what the final capsule design should look like.

Included in this document was a great amount of detail and some fifteen different

subsystems. Thus, it would be up to the McDonnell production engineers to expand on

these preliminary specifications and flesh out the design. They made the blueprints, and

also designed the tooling necessary to turn the capsule design into a piece of hardware.

After much collaboration with STG, McDonnell delivered their first capsule on April 1,

1960. Though it was stripped of many of its subsystems, this delivery showed that the

Mercury project was truly on its way toward launching a human into space. The final

capsule cost for the delivered twenty vehicles was $45.6M (FY ’59)

.

Figure 12: Mercury Capsule delivered by McDonnell.

10

The next manned spacecraft, project Gemini, was originally seen as an extension

of the Mercury program, except that the capsule would now carry two people. Since the

project was to be the same concept as Mercury, NASA decided that no competitive

bidding was required and the contract was awarded to McDonnell Aircraft again. With

Mercury still going at the time, the initial parameters set the contract ceiling limit as

$25M (FY ’61) with further cost parameters to be determined later. In the initial

contract, NASA told McDonnell to use equipment that had already been developed. This

is an early example of engineers realizing the benefit of using commercial-off-the-shelf

(COTS) parts

11

.

21

For the launch vehicle, NASA decided that the Air Force should be included in

some manner for this project. Therefore, they decided to “contract” the Air Force for the

launch vehicle systems. The Air Force was to provide the fifteen Titan II launch vehicles

and eleven Atlas-Agena target vehicles required for the program

. The Air Force in turn

contracted out Martin-Baltimore for the Titan and Lockheed Missiles and Space for the

Atlas-Agena. The DOD was contracted out to provide launch and recovery support, plus

aid in choosing the astronauts for the program. Including the Air Force added another

layer of management to the program. MSC could only set guidelines for launch vehicle

development; if they saw a problem, the procedure was for them to tell the Air Force,

which would then tell the private contractors. Also, since MSFC had already been

working on the Agena vehicle, NASA administration decided that MSFC should be in

charge of those vehicles. Thus, for changes in that program, MSC had to first tell MSFC,

which would then tell the Air Force, who would then tell Lockheed of the new business.

MSC completed its first down payment for the Atlas-Agena vehicles in March of 1962,

but the Air Force did not tell industry to begin work until a full two weeks later.

Many contractors, sub-contractors and vendors would be used for this program.

Over 200 of them had contracts worth $100,000 (FY ‘1966) or more

12

. Even though this

project was building upon Mercury, and was supposed to use COTS, the first system was

delivered to the launch site over a year late. The project ran into budget, design and

communication problems which caused this delay. The final spacecraft cost for the total

Gemini capsules was $696M (FY ’67).

Figure 13: Gemini Spacecraft.

22

The last manned spacecraft to launch from Earth before the STS launches began

was the Apollo capsule. This program was large and very challenging technically. Many

contractors and vendors would come together to work on this program. The prime

contract was to build the command module, the service module, an adapter and the

ground support equipment. Four contractors came back with proposals for the program.

The final choice was not without controversy as the Martin Company came back with the

highest rated overall score, which was a combination of three categories: technical

approach, technical qualification, and business

13

. North American Aviation (NAA),

which would later merge with Rockwell Corporation, had the highest technical

qualification score. Additionally, NAA had worked with NASA/NACA before on

projects such as the X-15 and Navajo. NASA administration chose NAA due to the fact

that they had worked with them before. However, word had leaked out that Martin Co.

had received the highest total score, and NASA administration had to answer before

Congress about why NAA was chosen for the contract.

There were many other contracts to be awarded for this ambitious program.

Grumman Aircraft was give prime contract for the Lunar Excursion Module (LEM).

They in turn used six major subcontractors. The launch vehicle was to be developed

from the Saturn program, for which MSFC would be in charge. Rocketdyne was the

contractor for the new engine, while Douglas, P & W, Convair, Chrysler and others were

used on the rest of the vehicle. The Saturn V, which would launch the Apollo astronauts,

used three separate stages. The first stage was contracted to Boeing, while Rockwell

received the second stage and Douglas the third. Apollo culminated with 15 manned

launches, and six successful moon landings. The use of contractors throughout such a

large program set the precedent for the STS vehicles.

23

Figure 14: Apollo Contractors and Physical Locations.

5.2 The STS Contractors

The STS program uses many different contractors throughout its structure. As

mentioned earlier, Rockwell, which eventually merged into Boeing, held the prime

contract for developing the orbiter. Rocketdyne, which merged with Rockwell, was the

prime contractor for the SSMEs. This section will further detail the prime contractors for

the STS program, list a few subcontractors, and show a breakdown of the contractor

structure in 1994. Again, 1994 is used because of the detail of the data that was found for

this year. The dollar amount and private workforce of each contractor is listed in Table

1; this table lists the contractor full-time equivalent of an employee. Figure 15 illustrates

the percentage of the STS program budget that goes to each contractor.

First, under the MSFC are the various hardware contractors. Rockwell

Rocketdyne, in conjunction with P & W, is the developer in charge of the SSMEs. These

engines are built and tested in various parts of California, Mississippi, and Florida. Two

of the subcontractors involved with this project are Honeywell and Hydraulic Research.

Lockheed Martin is in charge of the ET. They perform all designs and assemblies of the

tank. This tank has almost half a million parts and is produced at the MAF. Some of the

sub-contractors that work for Martin Marietta are Kaiser Aluminum, Reynolds Metals,

GE, and Grumman. Thiokol and USBI perform the work required for the SRBs. Thiokol

24

Table 1: 1994 Prime Contractor Breakdowns.

14

Contractor Function $M (FY '94)

Contractor

Workforce

Rocketdyne

SSME

$287 2018

P & W

SSME

$85 334

Martin Marietta

External Tank

$372 2635

Thiokol

Reusable Solid Rocket Motors

$404 2589

USBI

Solid Rocket Boosters

$152 1024

Lockheed

Shuttle Processing Contract

$533 6309

Rockwell

Orbiter Logistics

$199 1340

EG & G

Base Operations

$38 520

Rockwell 1

Orbiter Production, Ops/Launch

Support, Spares (Orbiter Project)

$288 1803

Rockwell 2

System & Ops Integration

(Program Office)

$151 699

Rockwell 3

Space Operations Contract

(Mission Operations)

$264 2214

Loral 1

Flight Software Development

$35 280

Loral 2

SR & QA

$20 251

Loral 3

Mission Support Contract (MCC

Dev)

$21 170

Lockheed

Engineering, Test & Analysis

$39 490

Krug

Medical Sciences

$4 39

Kelsey Seybold

Medical Sciences

$1 13

Johnson Eng.

Flight Crew Support

$12 120

Ham Std.

EVA

$25 119

SPAR

RMS

$13 60

Boeing

Flight Equipment Processing

$35 333

MSFCKSCJSC

is responsible for the design, manufacturing and testing of the solid rocket motors (SRM).

They perform testing at their facilities in Utah. Thiokol is also a major sub-contractor for

Lockheed Space Operations. They perform many portions of the Shuttle processing

work, “including inspection, assembly and checkout of the [SRBs] and [ET]

”.

Additionally, Thiokol also aids in recovering, performing disassembly, cleaning,

25

SSME, 8.31%

Shuttle

Processing

Contract, 22.28%

Orbiter Logistics,

4.73%

NASA

Institution,

18.71%

Orbiter

Production,

Ops/Launch

Support, Spares ,

6.37%

SRM, 12.76%

Other, 5.40%

Space Operations

Contract (Mission

Operations),

7.82%

System & Ops

Integration ,

2.47%

ET, 9.31%

KSC Base

Operations,

1.84%

Figure 15: 1994 STS Contractor Percentage Breakdowns.

14

Figure 16: Thiokol SRB Testing.

26

inspecting, and refurbishing the boosters. USBI is in charge of processing and

refurbishing the non-motor segments of the SRBs. USBI directly refurbishes the frustum,

plus the forward and aft skirt of the SRB. It also rebuilds the thrust vector control

system. USBI has also developed an efficient logistics system that helps manage over

70,000 required parts; this system is also copied for use on the ISS. Furthermore, USBI

performs many activities at the SRB Assembly and Refurbishment Facility at KSC.

These functions include replacement of insulation on the booster components, installation

of electronic and guidance systems, and installation of the parachutes.

At KSC in 1994, there were only three main contractors. However, the largest

contractor, Lockheed, held the biggest single contract within the STS program. This

Lockheed contract was for their Space Operations division. They were responsible for all

ground processing of the shuttle fleet at KSC. Their overall responsibility for shuttle

processing included operation of all the main facilities. These facilities include the

Orbiter Processing Facility (OPF), the Vehicle Assembly Building (VAB), and the

Orbiter Refurbishment and Maintenance Facility. Lockheed Space Operations also

maintains both shuttle launch pads: Launch Complexes 39-A and 39-B. Two more

facilities that are maintained within this contract are the logistics facility and the

hypergolic maintenance facility. Lockheed also provides services in support of the

shuttle at Vandenberg Air Force Base. Among the sub-contractors supporting Lockheed

are Thiokol, mentioned earlier, Grumman Technical Services, Johnson Controls,

Rocketdyne, USI, and EG & G.

Another contract operating out of KSC is for orbiter logistics by Rockwell. Since

Rockwell manufactured the orbiters’, this contract is appropriate for the base. At KSC,

Rockwell is involved with the integration of the Shuttle system, and helps to maintain the

technical integrity and configuration of the orbiters. Rockwell also provides logistic

support.

The last prime contractor shown above that operates out of KSC is E G & G

Florida: they are NASA’s base operations contractor for the Cape. They are responsible

for the operation of the utilities, maintenance of the facilities, administrative services and

technical operations. They are also the technical support for KSC computers and data

processing. Finally, E G & G is responsible for fire protection and security.

27

With the program office at JSC, most of the contractors in the STS program are

centered here. Rockwell occupies the largest amount due to its direct responsibility for

building the orbiter. It is through the JSC office that Rockwell manages production of

spares, and systems integration. Rockwell also helps support customer integration

through JSC. The MCC is operated by Rockwell employees; they are responsible for the

flight operations of the shuttle. Rockwell has numerous sub-contractors working for

them including SAIC, Honeywell and Allied Signal.

Another contractor who supports the MCC is Loral systems. They are responsible

for much of the software used by the STS program. Three separate contracts exist for

Loral: one for upgrades and development for the MCC, one for software for the shuttle,

and finally a contract for safety, reliability and quality assurance (S R & QA). Loral uses

the sub-contracting team of IBM, Syscom Development, GHG, Cimarron Software, and

Booz-Allen, in addition to others. Other direct contractors at JSC include Hamilton

Standard for the space suits, SPAR for robotic arm development and support, and

Johnson Engineering for flight crew support.

In 1994, there were many different contractors operating out of the three main

field centers that worked on the STS program. JSC was managing 86 different contracts

with over 56 direct contractors

. With budget cuts looming, and the belief that

overlapping responsibilities were plaguing the STS program, this region of NASA was

seen as an area for which costs could be improved. Over 28,000 employees, including

contractors and civil service workers, were charging to the shuttle. Various studies were

performed on the STS program, including the “Functional Workforce Review”, which

suggested that NASA could reduce its STS workforce by 13% without compromising

safety. In 1995, the “Kraft Report” was published that made various claims such as the

STS as a mature system. This report advocated drastic changes within the STS program,

such as consolidating “operations under a single entity”

8

. NASA’s independent safety

committee, the Aerospace Safety Advisory Panel, strongly disagreed with the Kraft

conclusions and rebuked it sharply. Additionally, many engineers within NASA felt that

the STS program was headed back towards the days of the pre-Challenger era and began

to voice their concerns. However, during this time period under the Clinton

administration, the government as a whole was looking for ways to reduce bureaucracy.

28

Goldin, the sitting NASA administrator, thought favorably upon the idea that NASA

could lead the way towards implementing the President’s vision. Thus, the Kraft report’s

recommendations were implemented, and NASA issued a contract for the prime Shuttle

operations. This contract would be wide ranging, and worth a large sum of money per

year. Rather than take their chances alone, both Lockheed and Rockwell teamed up to

form a new company, with each having a 50% stake. This new company, United Space

Alliance (USA), won the sole source contract in 1995, and a new era in Shuttle

operations was ushered in.

5.3 United Space Alliance

USA was awarded the contract based upon their experience and wealth of

knowledge. In actuality, it is doubtful that any other companies could have truly

competed for this contract, which became known as the Space Flight Operations Contract

(SFOC). The contract was split into two phases. Phase I duties included:

• Flight operations

• Mission design and planning

• Software development and integration

• Payload integration

• Logistics operations

• Astronaut and flight controller training

• Shuttle processing, launch and recovery

Figure 17: Dan Goldin announcing USA's Partnership with NASA.

29

Other companies submitting bids would know that if they won, they would have to

purchase much of the infrastructure that was put into place by both Rockwell and

Lockheed. Additionally, maintaining the orbiter would have become a big challenge to

any outside company because of its technical complexity. Regardless, USA won the

contract and became responsible for 61% of the shuttle operations. While some in

Congress had reservations about safety integrity, the contract was pushed through and

completed.

USA believed they could cut shuttle operating costs between $500M and $1B per

year (FY ’95). They would accomplish this through streamlining operations and

reducing personnel even further. At the time of formation, once the organization had

been completed, the number of employees in USA was 9,900. The total NASA STS

workforce at this time was just under 20,000.

The complete savings under USA never fully materialized as initially estimated.

Although exact savings for the program are difficult to ascertain, one estimate has put

them at $167M per year

. Unfortunately, these estimates have never been verified by the

General Accounting Office (GAO)

15

. The full cost savings were supposed to be realized

from the completion of Phase II responsibilities: these responsibilities included

transferring the control of the MSFC contracts for the main shuttle hardware over to

USA. Yet, MSFC managed to successfully resist this turnover and USA’s complete

streamlined approach would never be implemented.

5.4 Current Prime Contractor Breakdown

The STS program currently has about 92% of its total program budget earmarked

for contractors. A breakdown of the contractors is shown in Figure 18. USA operates the

largest part of the shuttle program. Boeing, which bought Rockwell, and therefore

Rockwell’s share of USA, is now responsible for the orbiter itself. Lockheed Martin

purchased Martin Marietta, and is now responsible for the ET. Compared to 1994,

NASA has been further removed from the STS program. MSFC is still in charge of the

big hardware contracts for the shuttle, with the exception being the SRB non motor

segment. That portion has been taken over by USA.

30

Thiokol

12%

Lockheed

10%

Rocketdyne

9%

Boeing

18%

NASA

9%

USA

42%

Figure 18: Current STS Breakdown.

While the move towards privatization has reduced costs of the STS program,

there is still room for improvement. With MSFC resisting the transfer of contracts for

further consolidation, cost savings may be missed. However, NASA admitted that they

had not performed a true cost benefit analysis with regards to full consolidation of the

contracts

16

. NASA simply believed that full consolidation of the contracts under a sole

entity would produce savings. While this did agree with the Kraft report findings, that

report was a source of controversy within NASA. Additionally, only one center, JSC was

ever considered as the source for full consolidation. Without a true cost benefit analysis,

that considered all options, NASA could not be entirely sure of how much the STS

program could be further reduced by consolidating the contractors.

31

6.0 Breakdown of 1994 Shuttle Costs

In this report, the most detailed data about the workforce and cost was obtained

from a 1994 study of the STS program

. The program has changed quite a bit since that

time, and the latter portions of this project will reflect that. However, this data will be

used to lay a foundation for why the STS program has such a high cost. Examining the

STS breakdown will also lead to ideas and plans that could result in cost savings to use

for the current structure.

As mentioned earlier, five main areas were designated as indirect and support

costs. These areas charge the STS program, yet do not work directly on the orbiter itself.

Each segment will be broken down into various sub-sections to show which functions of

the STS program are responsible for the high cost. Through an examination of each of

these sections, this project will show why such a high cost occurs, and later reveal

possible solutions for the current STS program and future manned spacecraft.

Each of the five areas of indirect and support cost can be broken down further into

eleven sub-regions. These eleven sub-regions are as follows

:

• Program Integration, Program Management, & NASA Institution

• Launch and Landing

• Solid Rocket Motor Project

• ET Project

• Orbiter Project and Logistics

• Mission Operations (JSC)

• SRB Project (MSFC)

• SSME Project (MSFC)

• Crew Operations and Training (JSC)

• Payload Support (KSC)

• Propellants (Cryogenics-KSC)

These sub-regions are mostly self-explanatory. The program integration category refers

to NASA management, administration and indirect support people that aid the STS

program in general. The propellants category only refers to the actual propellants and not

32

any of the support or facility cost that may be associated with it. These eleven sub-

regions will be used as an insight into the indirect and support costs of the STS program

6.1 Systems Management, Operations and Planning

This category of the STS program is responsible for a whopping 44% of the total

program cost in 1994. Throughout the shuttle program, there is a lot of management and

institution support that directly charges this area of NASA. Of the five indirect and

support cost regions, this area has the most man-hours being utilized. The top-level

functions of this area are defined below

17

:

• Customer relations

• Vehicle manifesting and scheduling

• Ground systems scheduling and management

• Software production (upgrades and mission unique)

• Personnel management

• Sustaining operations engineering (vehicle and facilities)

• Work control

• Public affairs

• Economic development

• Business management (contracts, procurement, legal, financial)

• Advanced planning

• S R & QA

Table 2 lists the breakdown of cost of each sub-region under the Systems

planning and management category. Figure 19 provides the breakdown of this category

into its eleven sub-regions using percentage values. As can be seen from both the table

and the chart, NASA management and institution costs are the biggest region from this

category. In the 1994 STS workforce breakdown

18

, as can be seen in Appendix A,

NASA institution has over 5000 employees who are charging the STS program under this

category. All of these employees are civil servants who work directly for NASA. Within

the institution heading, the workforce is further broken down into the field center and the

number of employees that fit within one of three categories: direct labor and travel,

indirect labor and travel, and operation of installation. With JSC as an example, the

33

Table 2: Systems Management Breakdown.

System Planning & Management: Sub-Regions $M (FY '94)

Program Management & NASA Institution 860.8

Launch & Landing 192

Crew Operations & Training 71.8

External Tank 31.4

Orbiter Project & Logistics 25

Mission Operations 135.4

Solid Rocket Boosters 52.1

Solid Rocket Motors 67.2

SSME 51.3

KSC P/L -

KSC Propellants -

Total 1487

MSN Ops

9%

SRB

4%

SRM

5%

Launch &

Landing

13%

Program

Management &

NASA

Institution

60%

ET

2%

Orb Proj &

Logistics

2%

Crew Ops &

Training

5%

Figure 19: Systems Management Area broken into Sub-Functions.

34

institution has 1662 employees who charge this area. 798 are for direct labor and travel,

166 are for indirect labor and travel, and 698 are responsible for the operation of the

installation. The direct labor employees are believed to be engineers and scientists who

support the STS program, while the indirect labor employees are secretaries and other

administrative employees who provide the overhead support to the engineers and

scientists. The operation of the installation category most likely refers to employees who

manage the utilities of the installation. The breakdown of this area is listed in Table 3.

Also shown in this table are the numbers of program management at each field center.

Table 3: Breakdown of Program Management and NASA Institution Employees.

Institution

5328

JSC 1662

Direct Labor & Travel 798

Indirect Labor & Travel 166

Operation of Installation 698

KSC 2197

Direct Labor & Travel 974

Indirect Labor & Travel 188

Operation of Installation 1035

MSFC 749

Direct Labor & Travel 242

Indirect Labor & Travel 37

Operation of Installation 470

Hq 615

Operation of Installation 615

SSC 105

Operation of Installation 105

Program Management

380

JSC 165

KSC 100

MSFC 100

SSC 15

EmployeesProgram Management & NASA Institution

The launch and landing sub-category is the next major area within the systems